Anti-slip fixing tray

A technology for fixing trays and trays, used in conveyor objects, printing, rotary printing machines, etc., can solve the problems of high scratch ratio, easy occurrence of silicone printing, damage, etc., to avoid sliding damage, reduce scratch ratio, application high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the following will be clearly and completely described in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them.

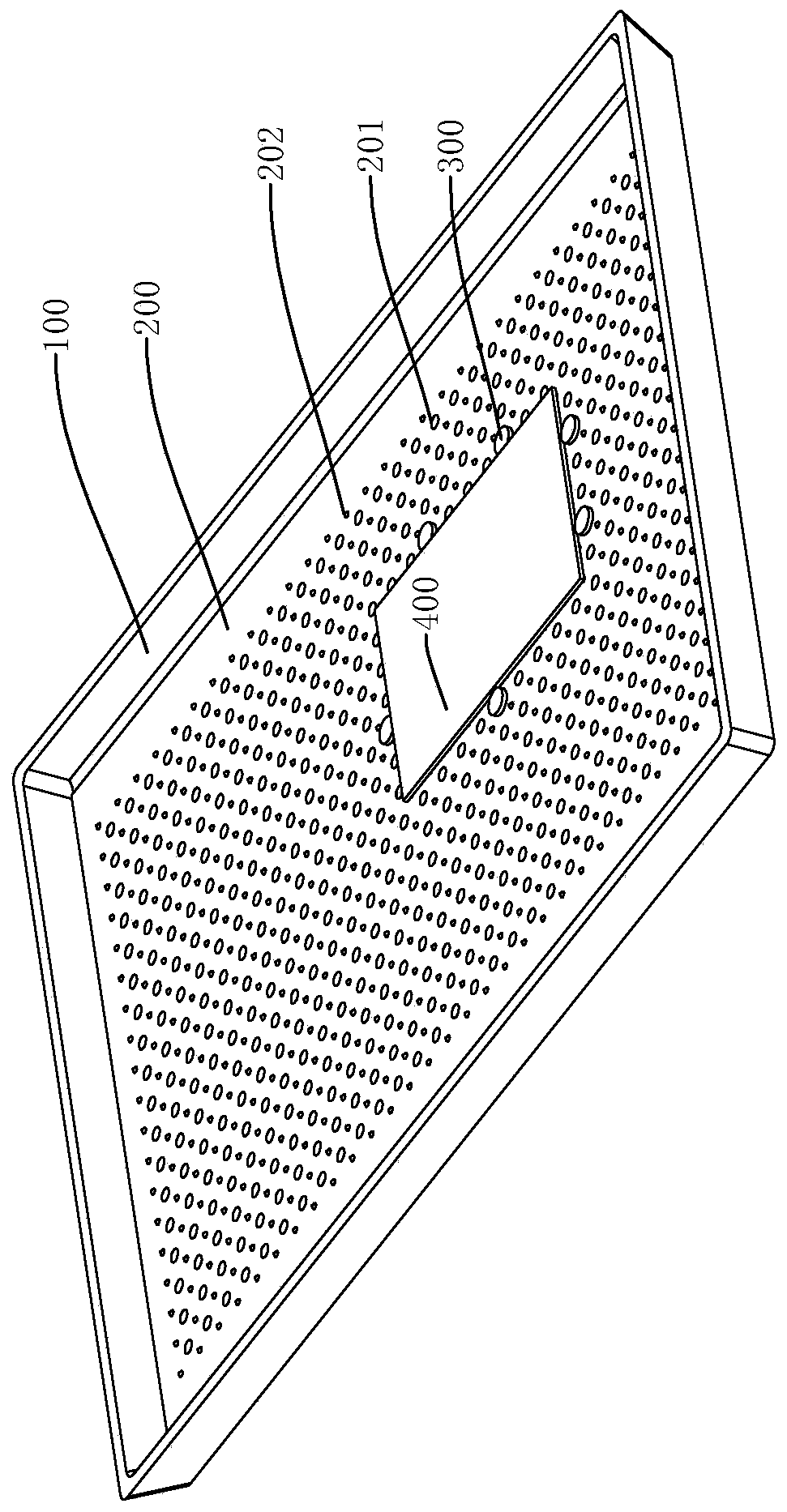

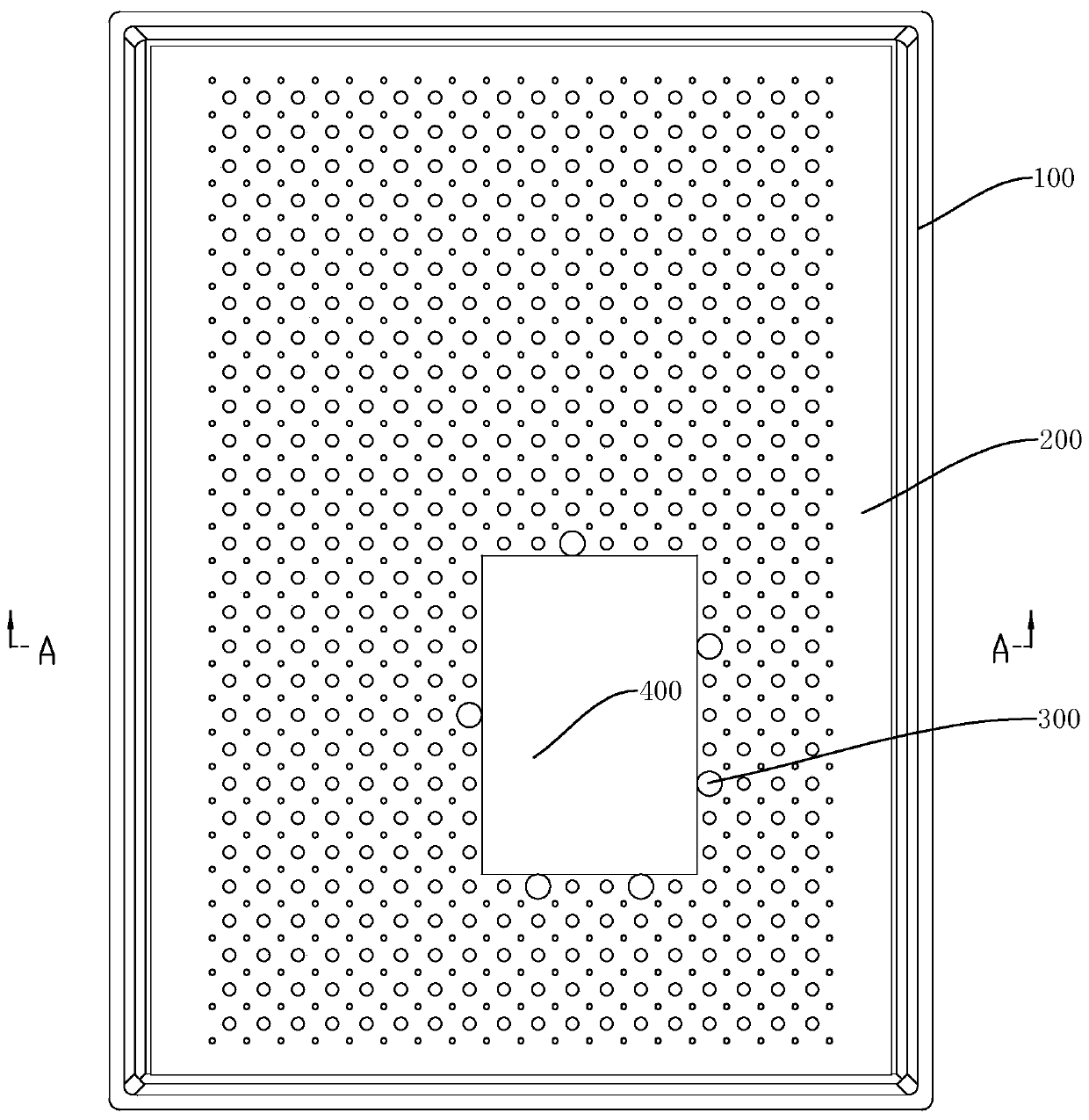

[0026] like Figure 1-3 and Figure 5 The shown non-slip fixed tray includes: a tray body 100 , a release pad 200 and several rubber nails 300 .

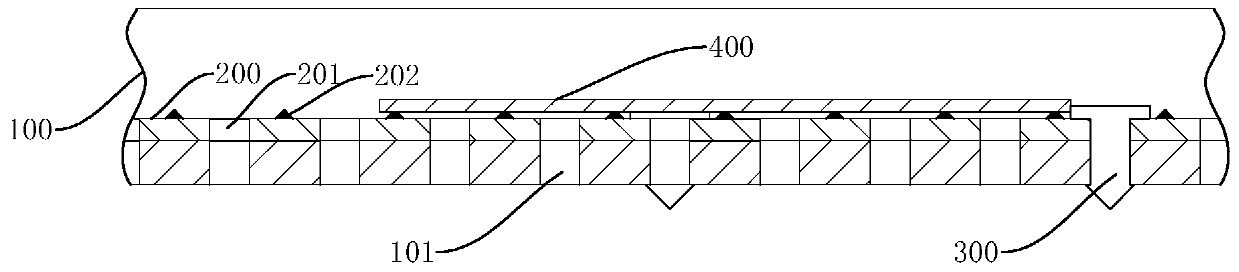

[0027] The tray body 100 is provided with a plurality of first through holes 101 , the release pad 200 is laid on the tray body 100 , and the release pad 200 is provided with a plurality of second through holes 201 corresponding to the first through holes 101 one by one.

[0028] The structure of rubber nail 300 is as follows Figure 4 As shown, it includes a positioning cap 301, a clamping post 302 and a plug head 303 arranged in sequence from top to bottom, and the plug head end of the rubber n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com