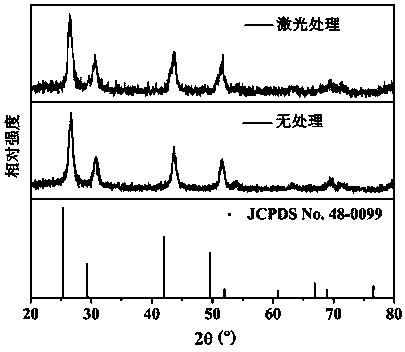

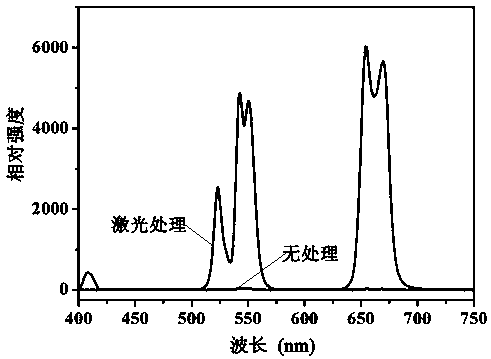

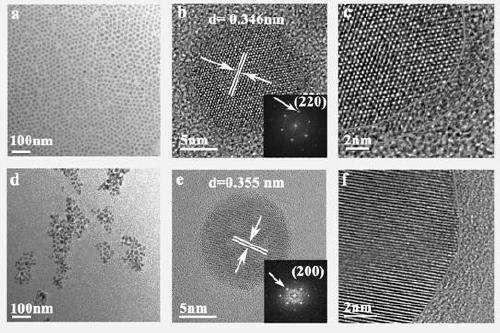

Method for improving luminous efficiency by laser treatment of up-conversion nano material

A nano-material and laser processing technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of small high brightness and difficult preparation, and achieve the effects of enhancing luminous intensity, good shape, and improving up-conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0036] Embodiment 1: A method for laser processing up-conversion of nanomaterials to improve luminous efficiency, the specific steps are as follows:

[0037] (1) Prepare the mixed rare earth nitrate solution of the rare earth matrix element (La), the rare earth luminescence center element (Er) and the rare earth sensitizer element (Yb): the oxide of the rare earth matrix element (La) 2 O 3 ), oxides of rare earth luminescence central elements (Er 2 O 3 ) And oxides of rare earth sensitizer elements (Yb 2 O 3 ) Was added to concentrated nitric acid (commercially available) and mixed uniformly, then heated at a constant rate to 200 ℃ and reacted at a constant temperature until crystals were produced, cooled to room temperature, then added deionized water and ultrasonicated for 10 min to obtain a mixed rare earth nitrate solution; The molar ratio of the rare earth matrix element, the rare earth luminescence center element and the rare earth sensitizer element is 78:2:20;

[0038] (2) M...

Example Embodiment

[0046] Embodiment 2: A method for laser processing up-conversion of nanomaterials to improve luminous efficiency, the specific steps are as follows:

[0047] (1) Prepare the mixed rare earth nitrate solution of the rare earth matrix element (Lu), the rare earth luminescence center element (Er) and the rare earth sensitizer element (Yb): the oxide of the rare earth matrix element (Lu) 2 O 3 ), oxides of rare earth luminescence central elements (Er 2 O 3 ) And oxides of rare earth sensitizer elements (Yb 2 O 3 ) Was added to concentrated nitric acid (commercially available) and mixed uniformly, then heated at a constant rate to 200 ℃ and reacted at constant temperature until crystals were produced, cooled to room temperature, then added deionized water and ultrasonicated for 30 min to obtain a mixed rare earth nitrate solution; The molar ratio of the rare earth matrix element, the rare earth luminescence center element and the rare earth sensitizer element is 78:2:20;

[0048] (2) Mix...

Example Embodiment

[0054] Embodiment 3: A method for laser processing up-conversion of nanomaterials to improve luminous efficiency, the specific steps are as follows:

[0055] (1) Prepare the mixed rare earth nitrate solution of the rare earth matrix element (Gd), the rare earth luminescent center element (Er) and the rare earth sensitizer element (Yb): the oxide of the rare earth matrix element (Gd) 2 O 3 ), oxides of rare earth luminescence central elements (Er 2 O 3 ) And oxides of rare earth sensitizer elements (Yb 2 O 3 ) Was added to concentrated nitric acid (commercially available) and mixed uniformly, then heated at a constant rate to 200°C and reacted at a constant temperature until crystals were produced, cooled to room temperature, then added deionized water and ultrasonicated for 30 minutes to obtain a mixed rare earth nitrate solution; The molar ratio of the rare earth matrix element, the rare earth luminescence center element and the rare earth sensitizer element is 78:2:20;

[0056] (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com