Retaining wall built on soft base and construction method of retaining wall

A technology for retaining walls and bases, which is applied in construction, infrastructure engineering, underwater structures, etc., and can solve problems such as endangering underground safety operations and slurry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

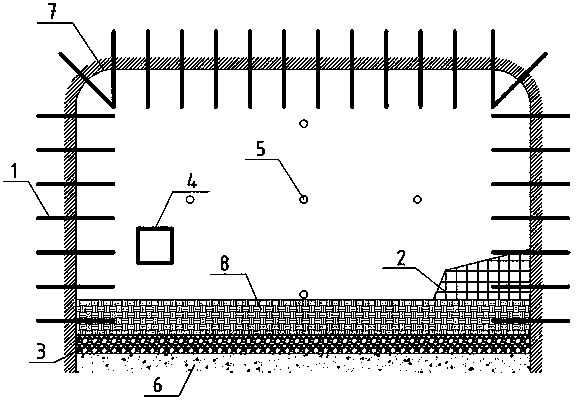

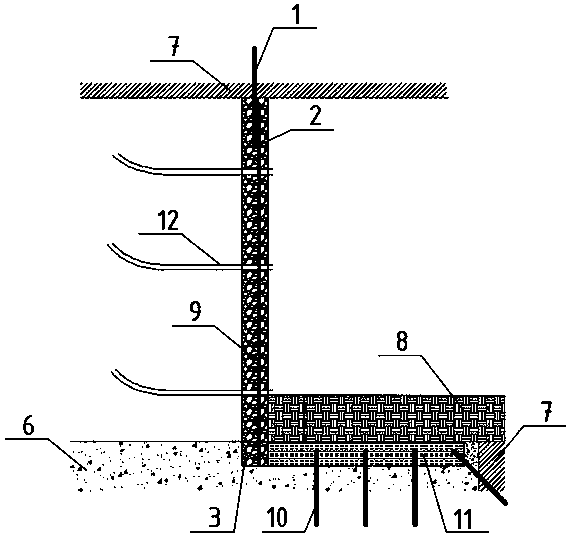

[0030] refer to figure 1 : A retaining wall built on a soft base, comprising a body of wall and a groove, the groove is a groove dug on the base, the body of the wall is installed in the groove, the body of the wall is connected to the roof by an anchor The rock, the side rock and the base are fixedly connected, the inside of the wall is provided with a steel mesh, and the wall is provided with drainage holes penetrating the thickness of the wall.

[0031] According to the size of the retaining wall to be constructed and the characteristics of the filling slurry, the force of the retaining wall is analyzed and calculated. The filling slurry undergoes three processes of settlement, dehydration, and condensation and hardening during the filling process. The force of the wall is the largest, assuming the conditional parameters of the mechanical analysis: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com