Fabricated wall panel mounting structure with stable support

A technology for stabilizing support and installing structures, which is applied in building construction, covering/lining, construction, etc., and can solve problems such as wall panel indentation, abnormal noise, and uneven wall surface, so as to improve support force and flatness , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

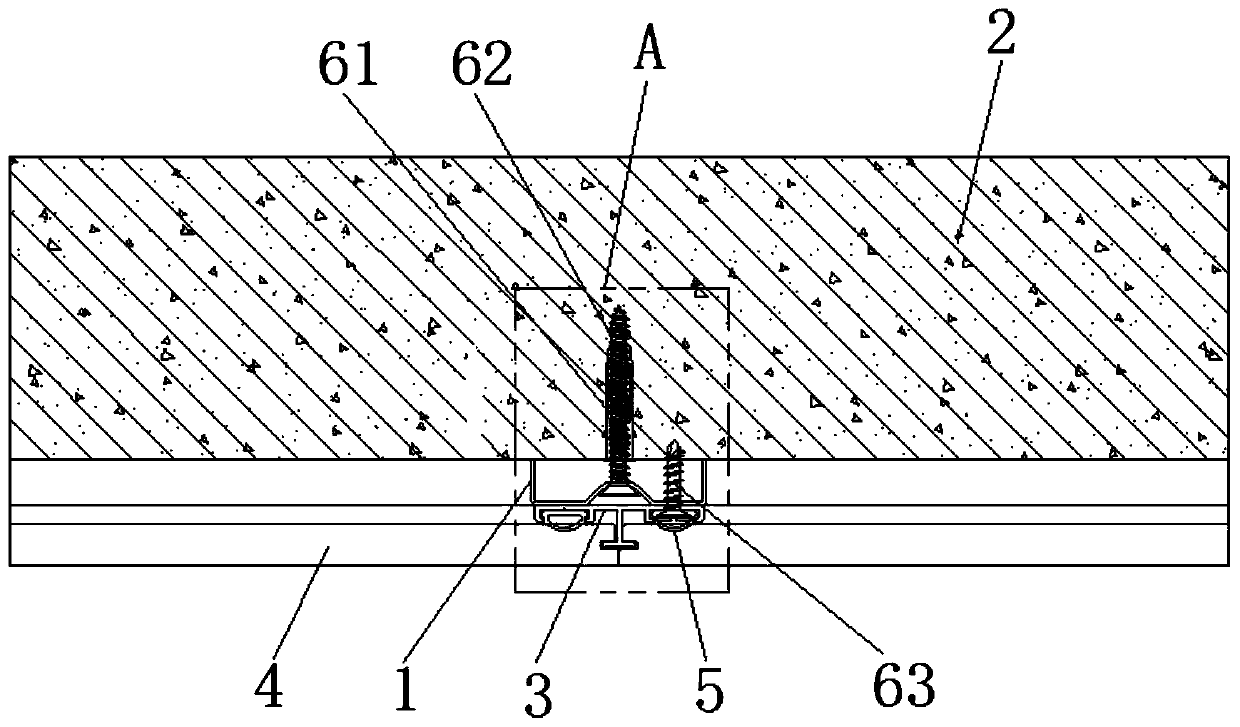

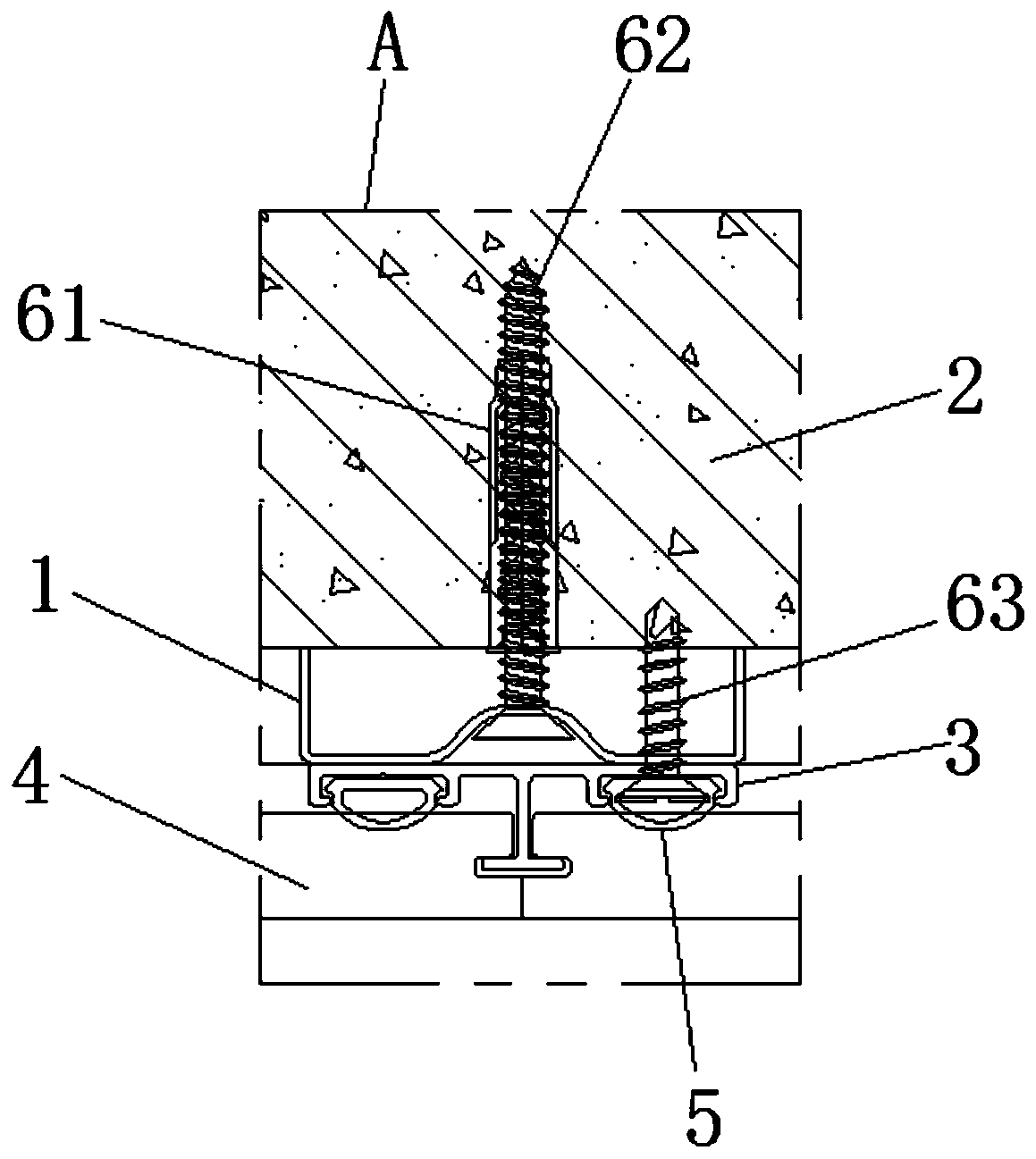

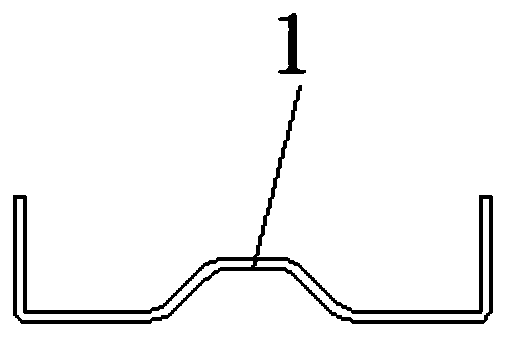

[0035] see Figure 1 to Figure 2 , the figure shows a stably supported assembled wall panel installation structure provided by Embodiment 1 of the present invention, which includes: keel 1, which is fixedly connected to the base wall 2; edge strip 3, which is the word "工" type aluminum alloy lines, the top of the trim strip 3 is fixedly connected with the keel 1, and the width of the top of the trim strip 3 is greater than the width of the bottom; , which is arranged in the edge strip 3, between the edge strip 3 and the wall panel 4, and symmetrically arranged on both sides of the edge strip 3. Among them, the keel 1 is an M38 light steel keel, and the keel 1 is connected with the base wall 2 through the expansion tube 61 and the first screw 62, and the expansion tube 61 is sleeved on the first screw 62; the edge strip 3 and the keel 1 pass through The second screw 63 is connected.

[0036] A stably supported assembled wall panel installation structure provided in this embod...

Embodiment 2

[0044] see figure 2 , Figure 4 , the figure shows a stably supported assembled wall panel installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Both sides of the long side of the side bar 3 are provided with "L" shaped hooks 31 , the hooks 31 are arranged symmetrically to form a slot 32 , and the buffer strip 5 is embedded in the slot 32 . Wherein, a triangular notch 33 is provided on the top of the card slot 32 . Through the setting of the above structure, the buffer strip 5 can be firmly clamped in the slot 32, and the hook 31 can also prevent the buffer strip 5 from falling off; in addition, the triangular notch 33 provides more squeeze space for the buffer strip 5 Pressure, easy to cushion, improve the cushioning effect.

Embodiment 3

[0046] see figure 2 , Figure 5 , the figure shows a stably supported prefabricated wall panel installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: buffer The bar 5 comprises a straight line 1 and an arc segment 52 closed and connected thereto. The straight line 51 corresponds to the side bar 3, and the arc segment 52 corresponds to the wall panel 4; The protruding card edge 53. Wherein, the buffer strip 5 is made of EPDM rubber. Through the setting of the above structure, the straight line section 51 is in contact with the card slot 32 to increase the clamping force, the arc section 52 is in contact with the wallboard 4, and the card edge 53 corresponds to the position of the hook 31, and will not fall off from the hook 31. , plus the material of EPDM rubber, so that the entire buffer effect reaches the best; meanwhile, the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap