Large-size imbricate cell structure

A large-scale, battery technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of bumps and fragments, battery bending, etc., to reduce the amount of bumps or fragments, improve the yield, and reduce the risk of component rework. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

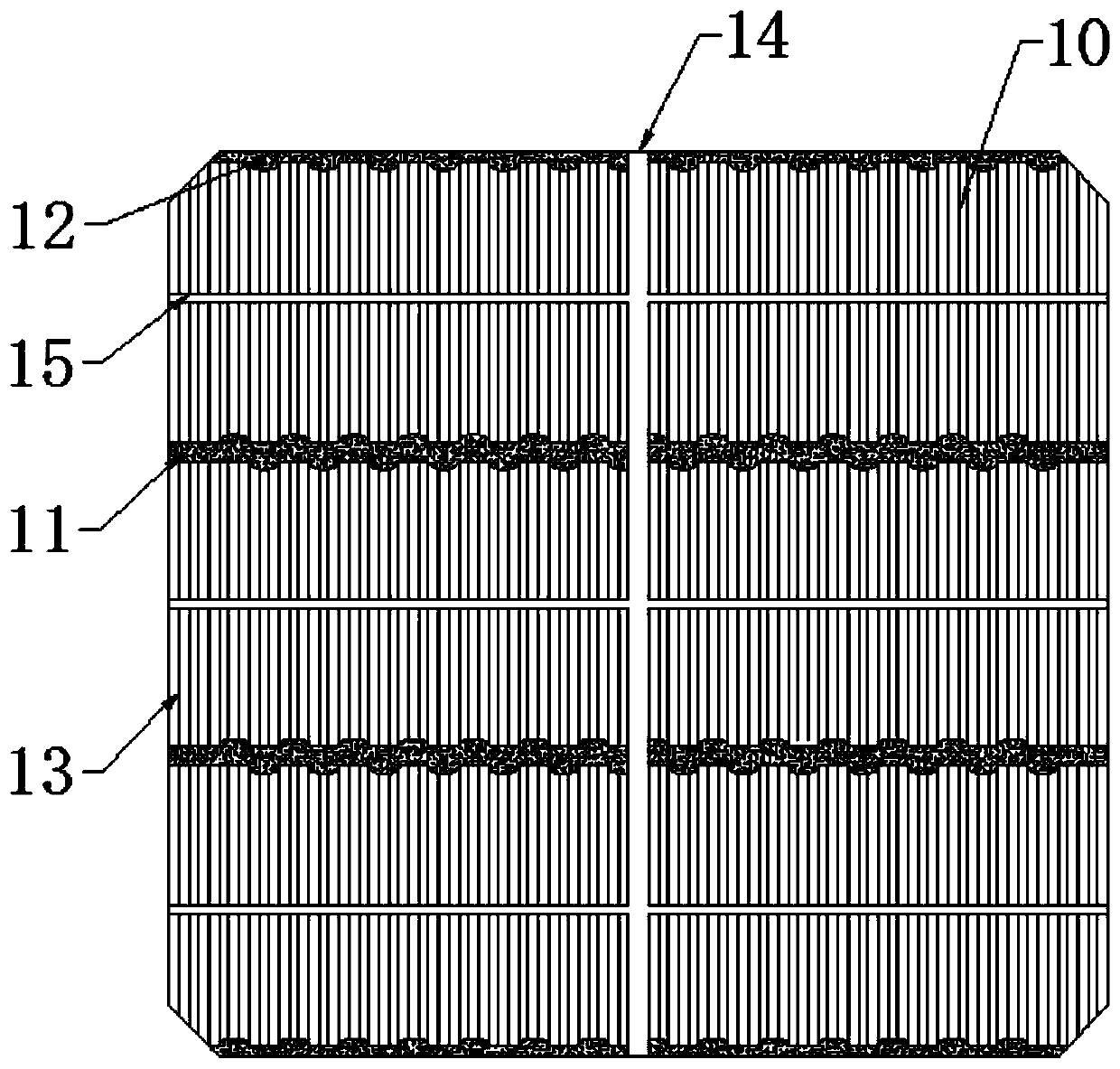

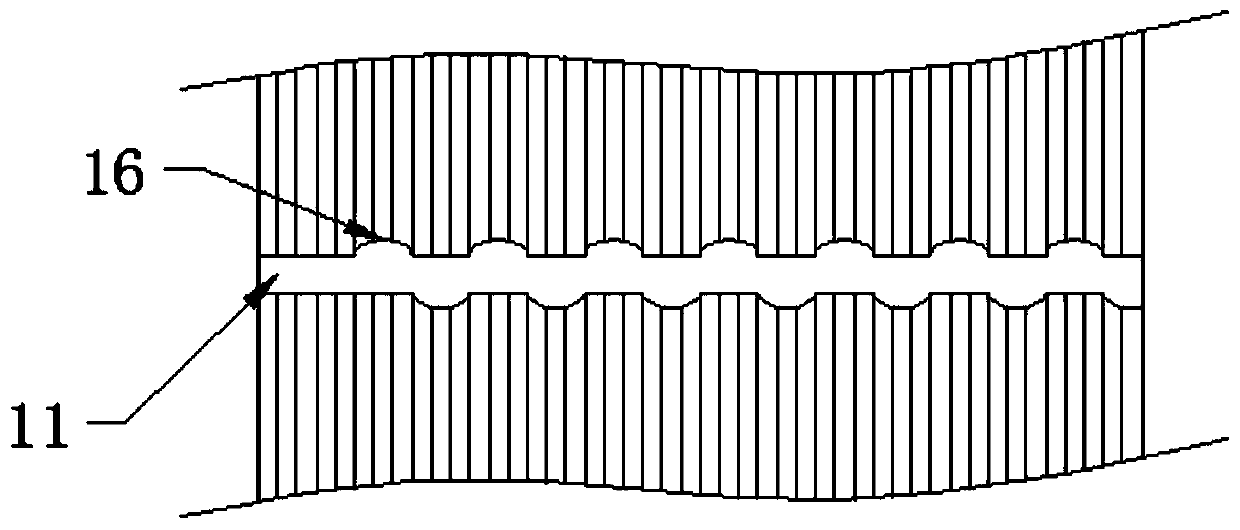

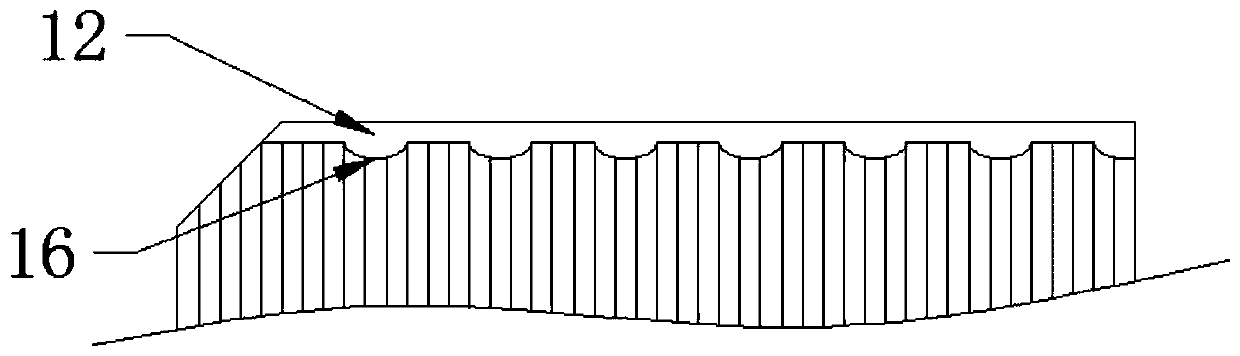

[0027] The present invention proposes a large-scale shingled battery structure, such as Figure 1-5 As shown, it includes a front side 10 and a back field 20. The front side 10 includes several first main grids 11 and second main grids 12 arranged in parallel. The first main grid 11 is located inside the front side 10, and the second main grids 12 are respectively located upper and lower edges, specifically as figure 1 shown. The back field 20 includes a plurality of back electrodes 21 arranged in parallel. The back electrodes 21 are arranged in parallel with the first main gate 11 and offset. The structure of the back electrodes 21 is the same as that of the first main gate 11 . In this embodiment, there are two first main grids 11 and two second main grids 12, the first main grids 11 are respectively located on the upper half and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com