Sliding rail assembly and sliding rail kit thereof

A slide rail assembly and slide rail technology, which is applied to furniture parts, household appliances, drawers, etc., can solve problems such as unsmooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

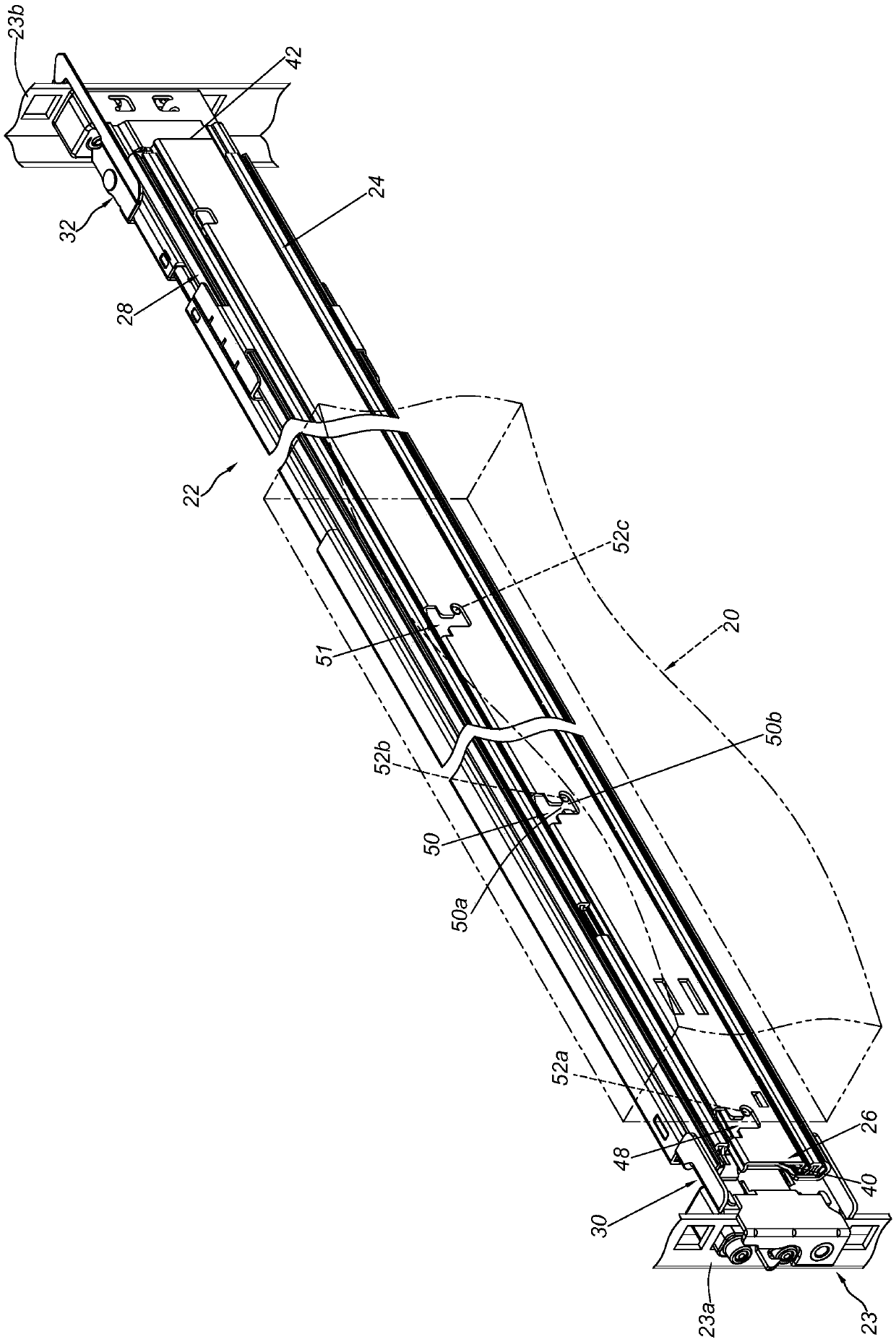

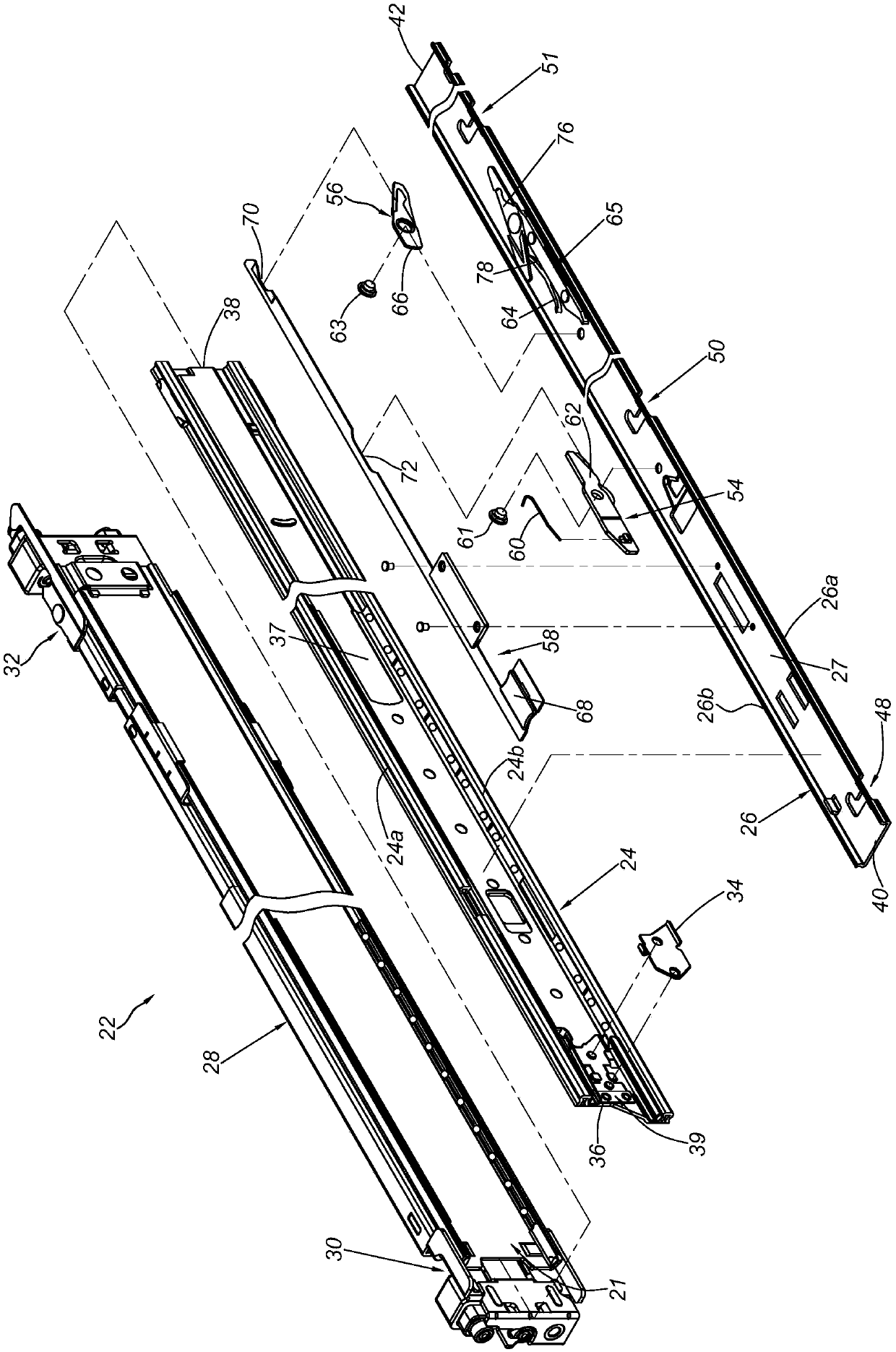

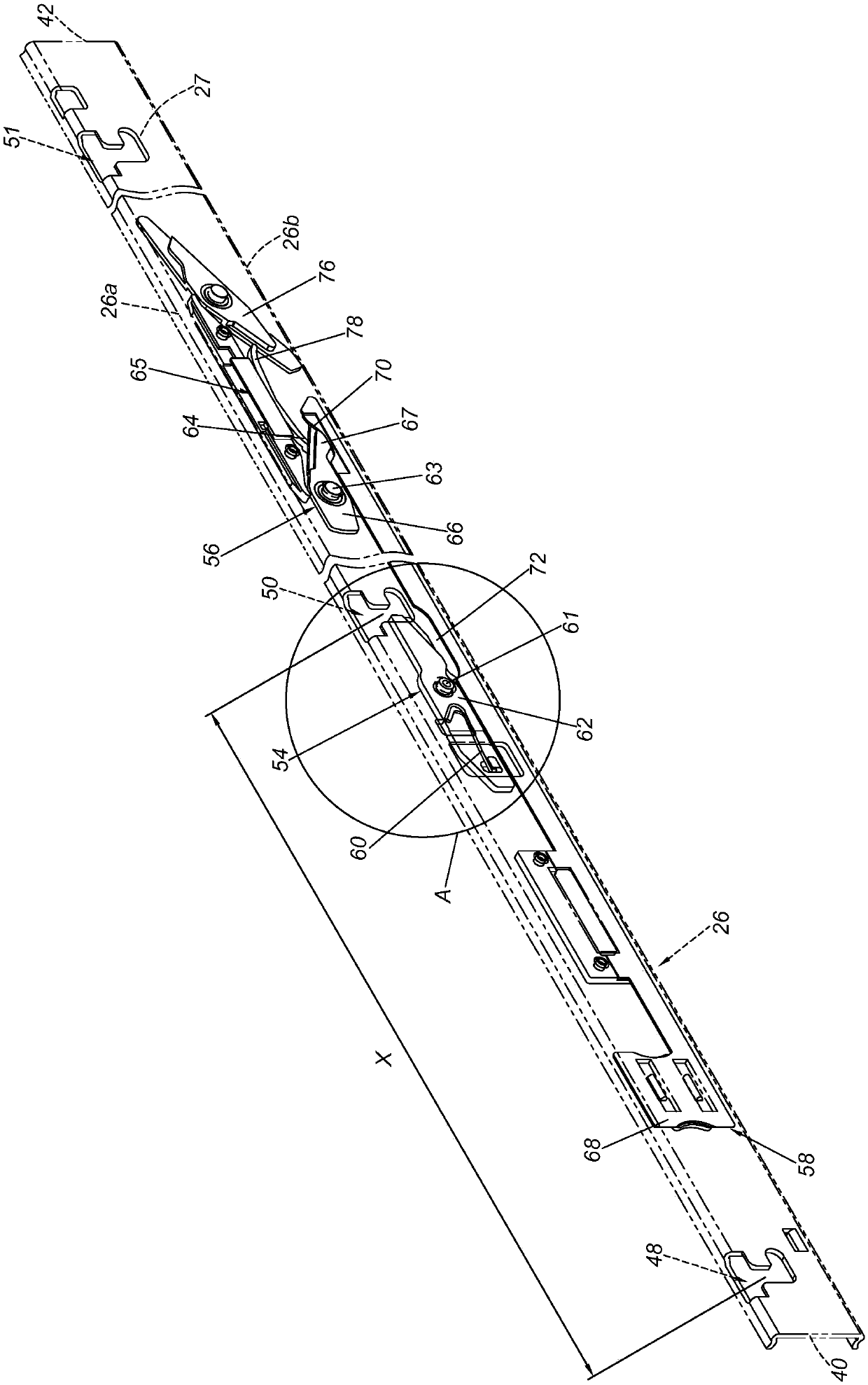

[0031] like figure 1 and figure 2 As shown, in a rack system, a load 20 can be mounted to a rack 23 (rack) through a slide rail assembly 22 . The carrier 20 is, for example, an electronic device, a chassis, or a drawer. The slide rail assembly 22 includes a first rail 24 and a second rail 26 displaceable longitudinally relative to the first rail 24 . Preferably, a third rail 28 is also included. Wherein, the first rail 24 is movably installed between the third rail 28 and the second rail 26 .

[0032] The third rail 28 can be mounted to a first column 23 a and a second column 23 b of the rack 23 through a first bracket 30 and a second bracket 32 . Furthermore, the third rail 28 has a channel 21 .

[0033] The first rail 24 is movably mounted to the channel 21 of the third rail 28 . A stop 34 is arranged on the first rail 24 . The blocking portion 34 is located between a first end 36 (eg front end) and a second end 38 (eg rear end) of the first rail 24 . Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com