Rail rust removal grinding device

A track and grinding mechanism technology, applied in the field of rail transit, can solve the problems of accelerating track aging and affecting the service life of the track, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

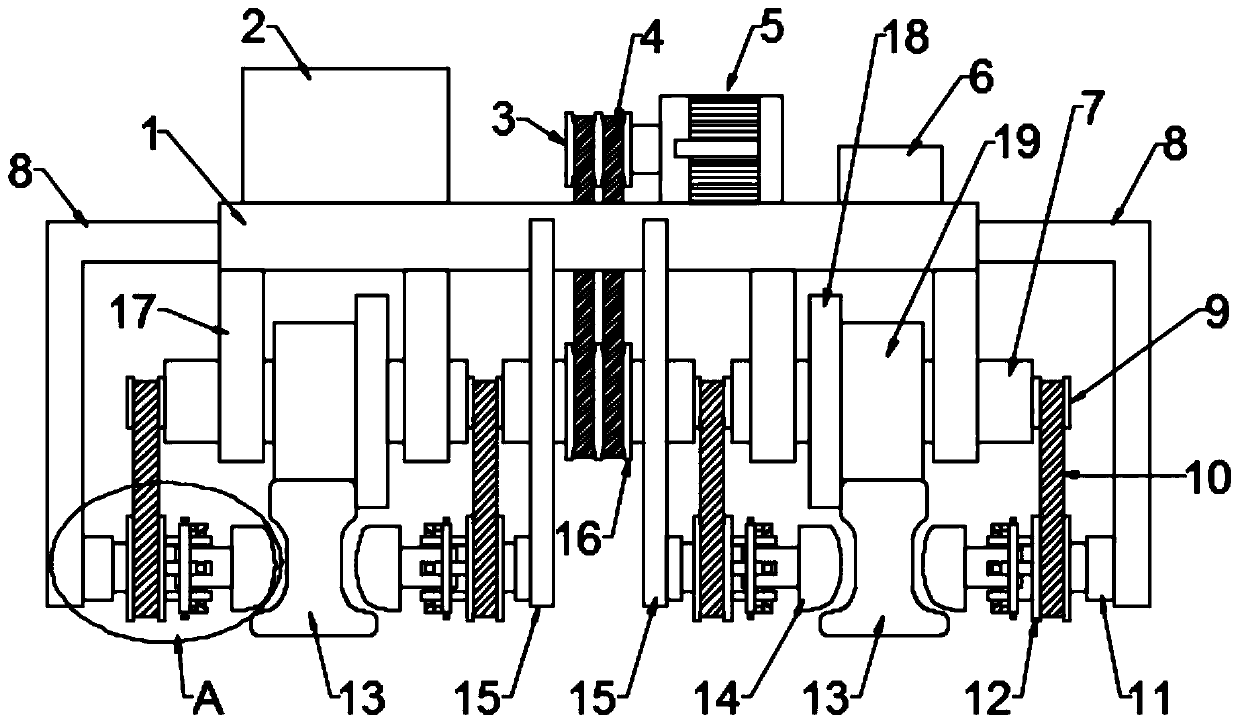

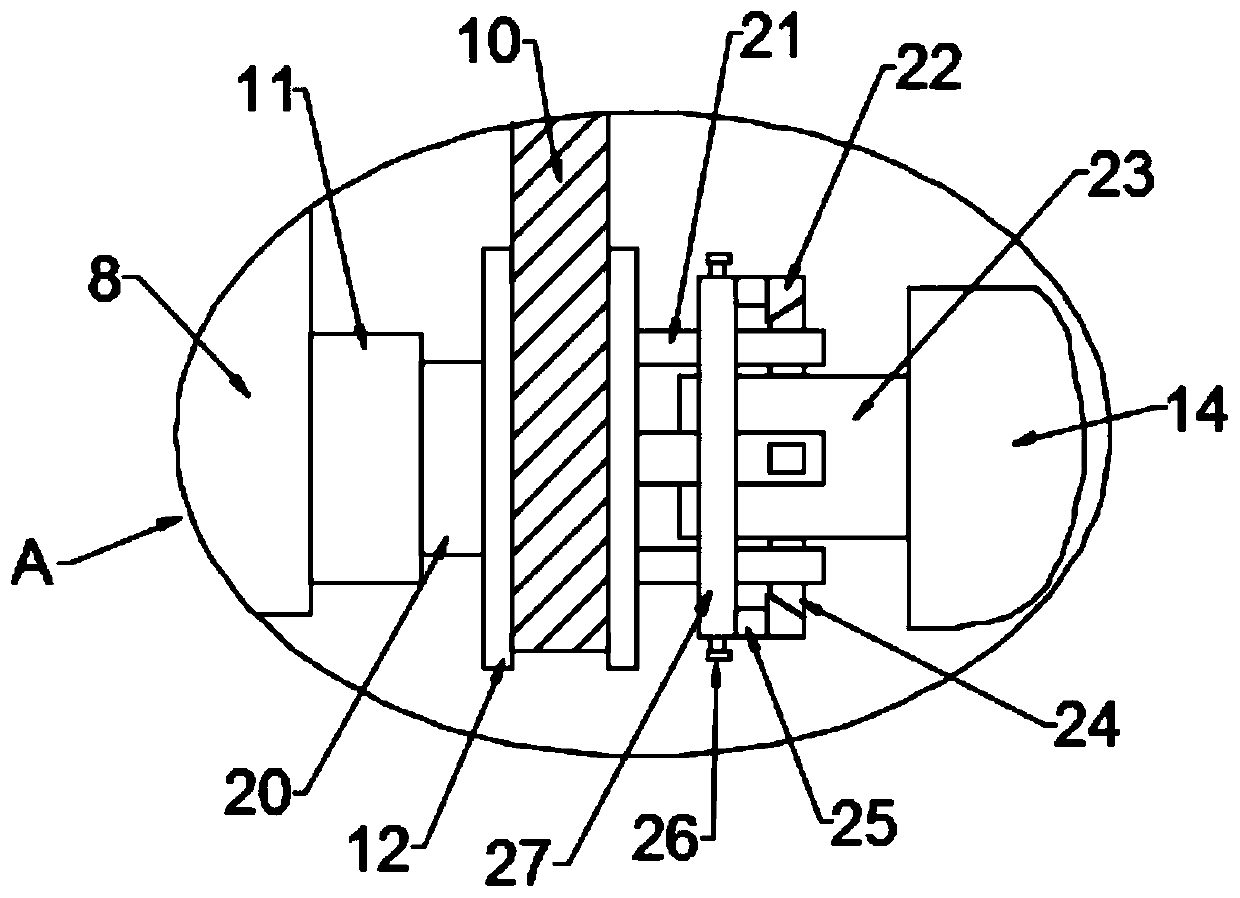

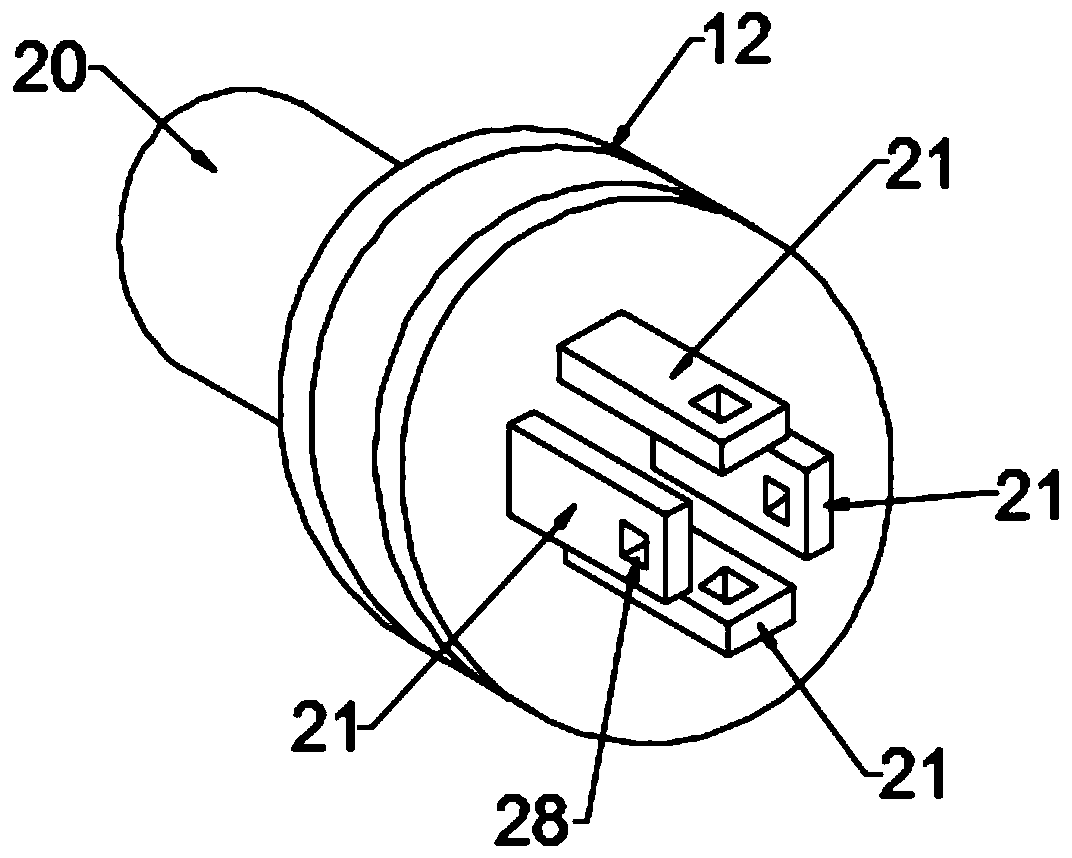

[0034] see Figure 1-5 , in an embodiment of the present invention, a track derusting and polishing device includes a base 1, a support plate 17 is installed on the bottom of the base 1, the bottom bearing of the support plate 17 is connected with a support shaft 7, and a wheel is arranged on the support shaft 7. 19, the inner side of the wheel 19 is provided with a rim 18;

[0035] The base 1 is provided with a driving mechanism for driving the wheels 19 to rotate, and the track derusting and polishing device also includes a polishing mechanism for derusting the side of the rail 13; the driving mechanism can drive the wheels 19 to rotate, and reuse The cooperation of the wheel rim 18 and the track 13 drives the wheel 19 to roll on the track 13, so that the track derusting and polishing device moves along the track 13; meanwhile, the side of the track 13 can be polished to remove rust by the grinding mechanism. Extend the service life of the track 13.

[0036] Further, the d...

Embodiment 2

[0051] see Figure 6 , in the embodiment of the present invention, a track derusting and polishing device is different from embodiment 1 in that a fixed column 30 is fixed on the base 1, and a solar panel 31 is installed on the fixed column 30; through the solar panel 31, the Solar power is used to generate electricity, and the electric energy is stored in the storage battery 2 for the operation of the drive motor 5, which has the effect of saving energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com