A multi-angle adjustable clamping machine for pipeline installation

A pipe installation, multi-angle technology, applied to workpiece clamping devices, manufacturing tools, etc., can solve problems such as soreness, unfavorable pipe installation, etc., and achieve the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

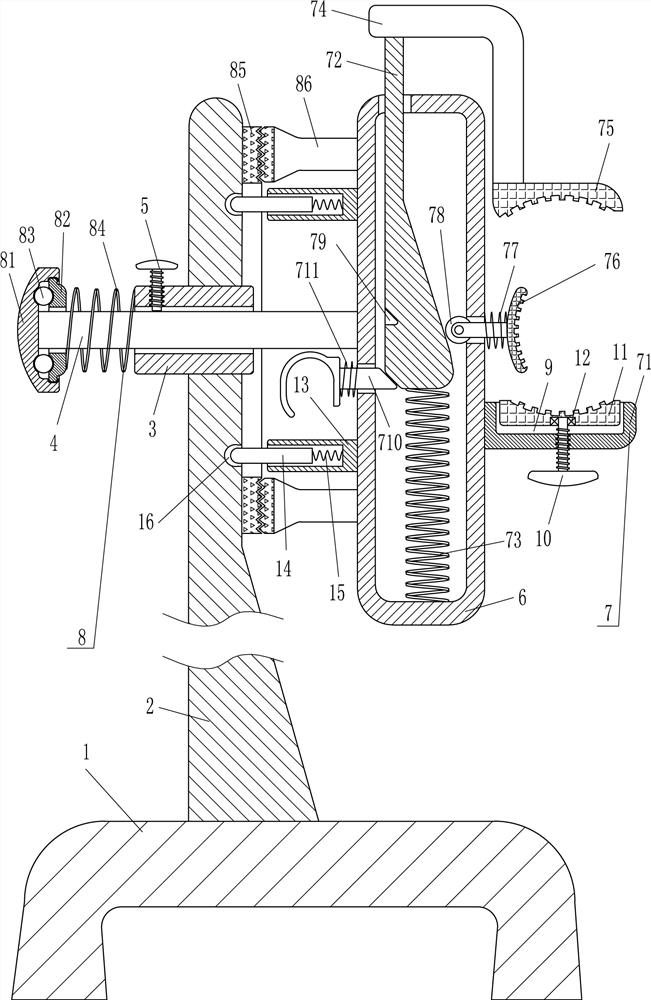

[0020] A multi-angle adjustable clamping machine for pipeline installation, please refer to figure 1 , including a base 1, a support plate 2, a shaft sleeve 3, a movable rod 4, a fastening bolt 5, a hollow tube 6 and a clamping mechanism 7, a support plate 2 is installed on the top of the base 1, and a shaft is embedded in the upper part of the support plate 2 Sleeve 3, the movable rod 4 is arranged in the shaft sleeve 3, the fastening bolt 5 matched with the movable rod 4 is arranged on the left side of the shaft sleeve 3, the hollow tube 6 is installed on the right end of the movable rod 4, and the hollow tube 6 is provided on the right Clamping mechanism 7.

[0021] The clamping mechanism 7 includes a fixed splint 71, a wedge block 72, a first spring 73, an L-shaped bar 74, a movable splint 75, a push rod 76, a second spring 77, a guide wheel 78, a clamp bar 710 and a third spring 711, The lower part of the outer right side of the hollow tube 6 is equipped with a fixed spl...

Embodiment 2

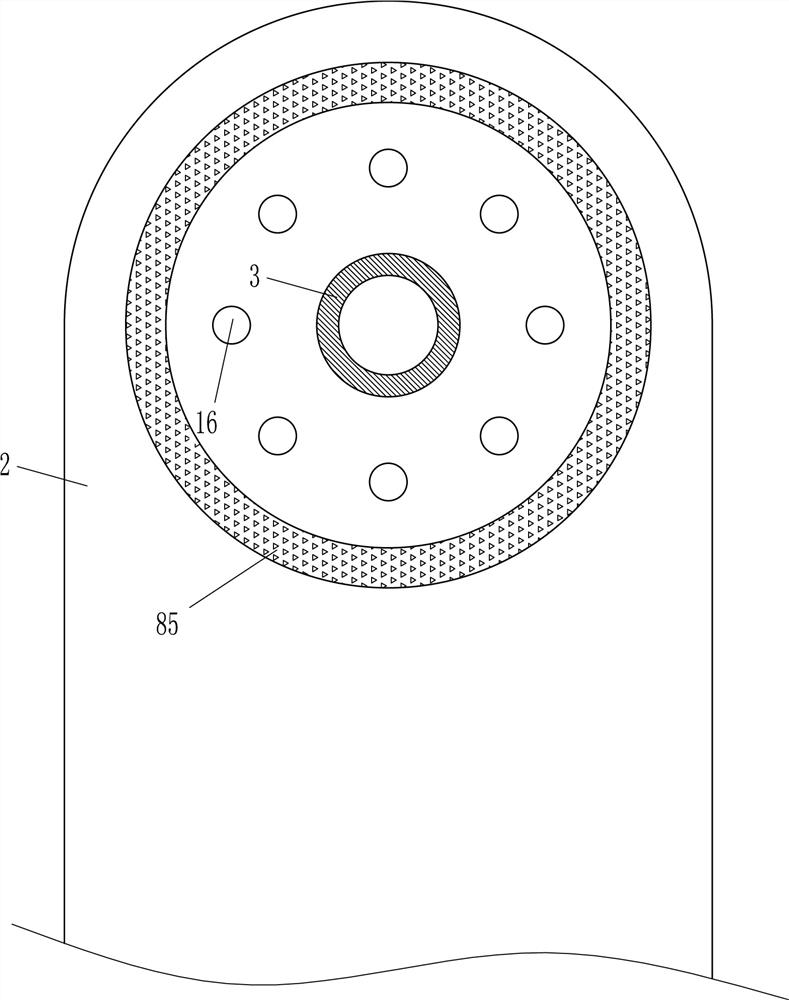

[0025] On the basis of Example 1, please refer to figure 1 and figure 2 , also includes clamping device 8, and clamping device 8 comprises circular groove plate 81, annular plate 82, ball 83, the 4th spring 84, annular friction plate 85 and friction bar 86, movable rod 4 left ends are fixedly connected with circle Shape groove plate 81, circular groove plate 81 inner movable type is provided with annular plate 82, and movable bar 4 passes through annular plate 82, and evenly spaced between annular plate 82 left side and circular groove plate 81 inner left side is provided with The ball 83, the fourth spring 84 is connected between the right side of the annular plate 82 and the left side of the shaft sleeve 3, the fourth spring 84 is wound on the movable rod 4, and an annular friction plate 85 is installed on the upper right side of the support plate 2, The upper and lower sides of the outer left side of the hollow tube 6 are equipped with friction rods 86, and the left end o...

Embodiment 3

[0028] On the basis of Example 2, please refer to figure 1 , also includes screw rod 10, movable block 11 and bearing 12, has groove 9 on the upper part of fixed splint 71, is provided with movable block 11 slidingly in groove 9, and bearing 12 is embedded in the bottom of movable block 11, and fixed splint 71 The lower part is screwed with a screw rod 10, and the top of the screw rod 10 is connected with the bearing 12 through an interference connection.

[0029] Also comprise sleeve 13, slide bar 14 and the 5th spring 15, both sides of hollow tube 6 outer left side surface are fixedly connected with sleeve 13, slide type is provided with slide bar 14 in sleeve 13, slide bar 14 right-hand sides A fifth spring 15 is connected with the sleeve 13 , and eight grooves 16 are evenly spaced on the upper right side of the support plate 2 , and the grooves 16 cooperate with the slide bar 14 .

[0030] The working process of this device is as follows: When the PVC pipe is fixed, if th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com