A kind of solid-liquid propellant and its preparation method and use method

A technology of propellant and liquid oxidant, applied in offensive equipment, explosive processing equipment, explosives, etc., can solve the problems of short combustion time, small combustion specific impulse, and limited use, and achieve low environmental pollution, high energy, and high safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of solid-liquid propellant, described liquid oxidizer: comprises the following steps:

[0040] Step (1), take raw materials according to the following mass percentage content:

[0041] Solid oxidant 5-80%, hydrogen peroxide 20-95%;

[0042] Step (2), adding the solid oxidizing agent described in step (1) into the liquid hydrogen peroxide and stirring to form a uniform solution.

[0043] A kind of preparation method of solid-liquid propellant is characterized in that described solid fuel: comprises the following steps:

[0044] Step (1), take raw materials according to the following mass percentage content:

[0045] 10% to 60% of metal and metal hydride fuel, 0 to 90% of explosive, and 0 to 30% of forming agent.

[0046] Step (2), mixing the raw materials described in step (1) uniformly to make slurry or powder;

[0047] In step (3), the slurry or powder described in step (2) is loaded into a mold, and the required shape is made by heatin...

Embodiment 1

[0078] This embodiment provides a solid-liquid propellant:

[0079] 1. See Table 1 for the formula of solid-liquid propellant:

[0080] Table 1 A kind of solid-liquid propellant formula

[0081] Table 1a Liquid Oxidizers

[0082]

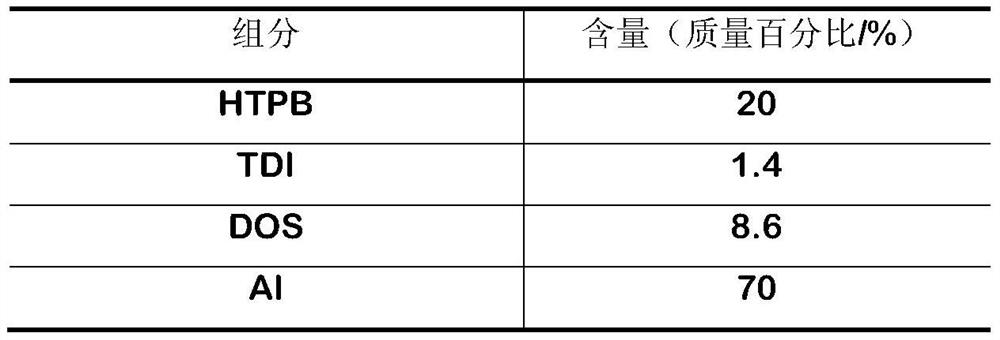

[0083] Table 1b Solid Fuels

[0084]

[0085] Liquid-solid ratio (mass ratio of liquid oxidant to solid fuel): 1.5~2.5:1

[0086] 2. The preparation method of solid-liquid propellant comprises the following steps:

[0087] Step (1): taking raw materials according to the formula in Table 1a;

[0088] Step (2): Add the ADN in the raw material to H 2 o 2 (concentration 90%), stir and mix evenly; obtain liquid oxidant.

[0089] Step (3): taking raw materials according to the formula in Table 1b;

[0090] Step (4): Add plasticizer DOS, Al powder, and curing agent TDI to the adhesive HTPB system at 50-60°C, mix evenly to obtain propellant slurry, vacuum cast, and cure at 50-70°C for 120- After 168 hours, solidified solid fuel can be prepare...

Embodiment 2

[0095] This embodiment provides a solid-liquid propellant:

[0096] 1. See Table 2 for the solid-liquid propellant formula:

[0097] A kind of solid-liquid propellant formula of table 2

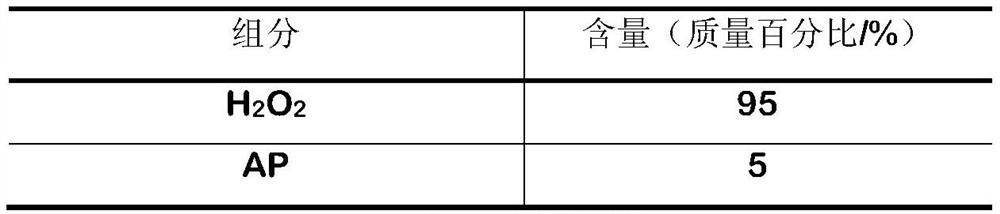

[0098] Table 2a Liquid Oxidizers

[0099]

[0100] Table 2b Solid Fuels

[0101]

[0102] Liquid-solid ratio: 1.5~2.5:1

[0103] 2. The preparation method of solid-liquid propellant comprises the following steps:

[0104] Step (1): taking raw materials according to the formula in Table 2a;

[0105] Step (2): Add AP in the raw material to H 2 o 2 (concentration 90%), stir and mix evenly; obtain liquid oxidant.

[0106] Step (3): taking raw materials according to the formula in Table 2b;

[0107] Step (4): Add plasticizer DOS, Al powder, AlH3, and curing agent TDI to the adhesive HTPB system at 30-40°C, mix evenly to obtain propellant slurry, vacuum cast, and cure at 40-45°C After 120-168 hours, a solid fuel that is solidified and molded can be obtained.

[0108] 3. The obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com