Leather surface treatment equipment

A technology for surface treatment and equipment, applied in the field of leather surface treatment equipment, can solve the problems that the surface treatment uniformity of leather products cannot be guaranteed, the retro effect of leather products is affected, and the labor intensity is high, so as to protect from damage, ensure the health of workers, The effect of avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

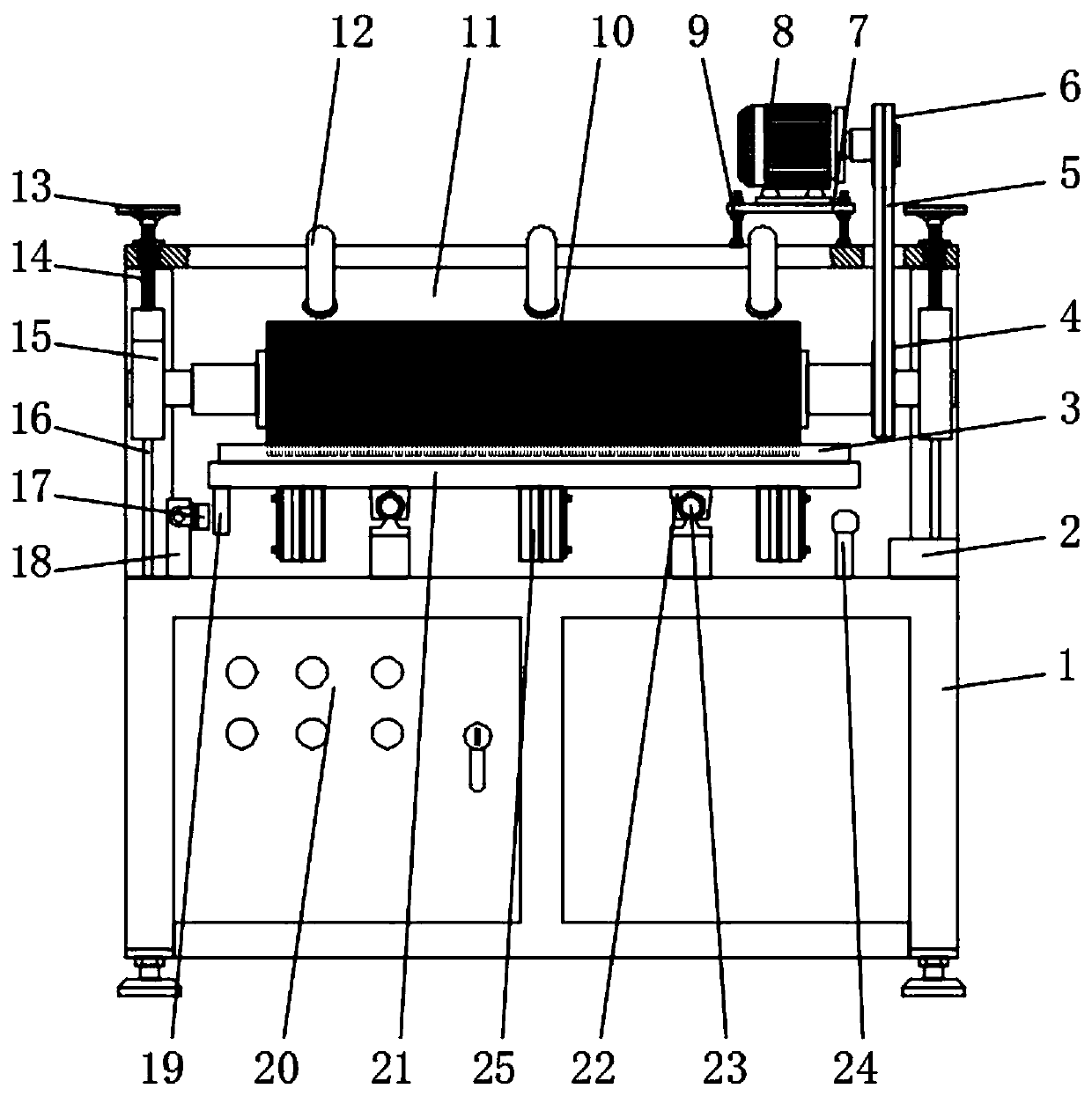

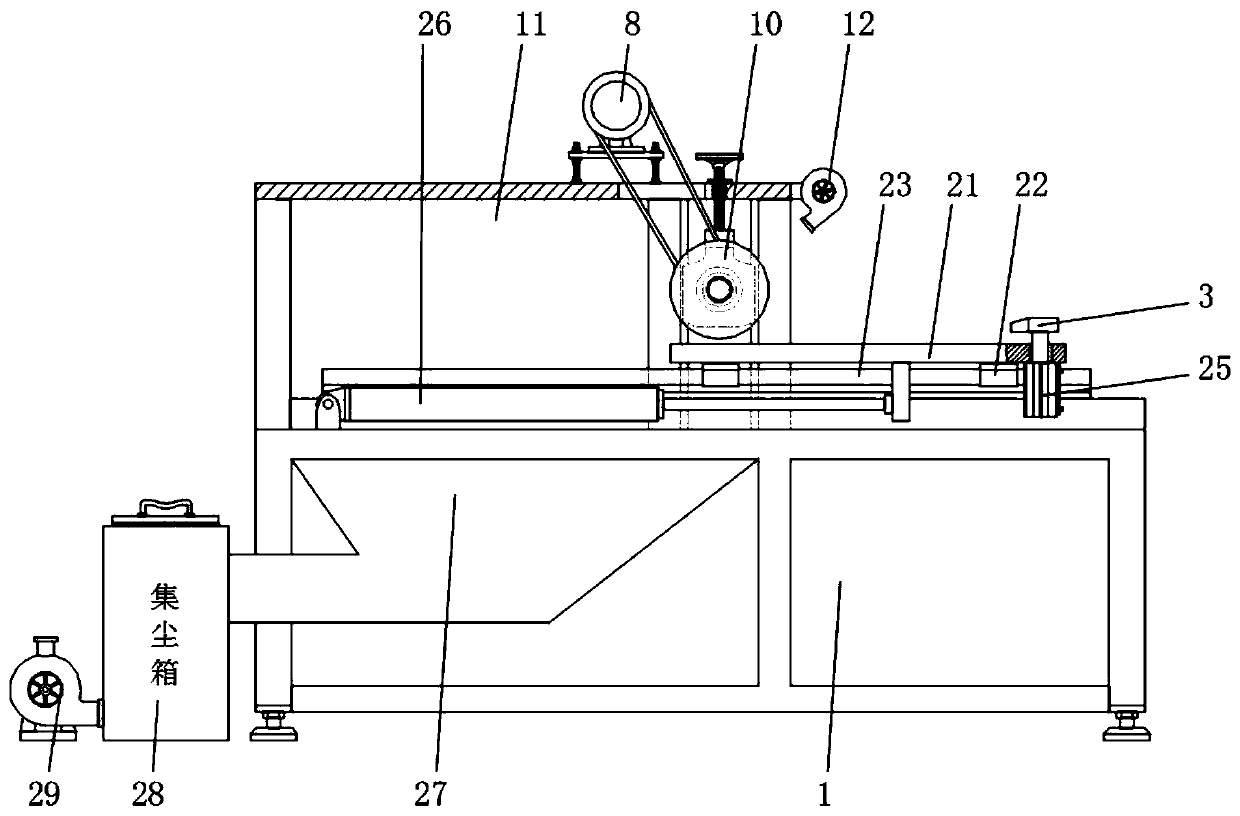

[0032] Embodiment one, with reference to Figure 1-2 , a kind of leather surface treatment equipment, comprising equipment body 1 and distributing roller 10, is provided with grinding chamber 11 above equipment body 1, and inside of grinding chamber 11 both side walls are all slidingly connected with seated bearing 15 by guide bar 16, and grinding Inside the warehouse 11, a distribution roller 10 is installed through a belt seat bearing 15. The distribution roller 10 includes a roller shaft and multi-layer cloth, and one end of the distribution roller 10 is equipped with a driven pulley 4 on the roller shaft, and the driven pulley 4 passes through the belt 5 The transmission is connected with a driving pulley 6, and the driving pulley 6 is installed on the output shaft of the motor 8, the motor 8 is fixed on the adjustment seat 7 by screws, and the adjustment seat 7 is fixed on one side of the top surface of the grinding chamber 11 by the adjustment screw rod 9, The top of the...

Embodiment 2

[0033] Embodiment two, refer to Figure 1-2 , the top surface of the equipment body 1 is slidably connected to the grinding table 21 through the linear guide rail 23 and the slider 22, and the linear guide rail 23 extends to the inside of the grinding chamber 11, and the lifting cylinder 25 is installed on the bottom surface of the grinding table 21, and the telescopic rod end of the lifting cylinder 25 The head passes through the grinding table 21 and is connected to the pressure plate 3. When the lifting cylinder 25 is lowered to the position, the bottom surface of the pressure plate 3 is attached to the top surface of the grinding table 21. The top surface of the equipment body 1 is located inside the grinding chamber 11. A forward and backward cylinder 26 is installed, and the forward and backward cylinder 26 The end of the telescopic rod is connected with the bottom surface of the grinding table 21, and the leather can be fixed on the surface of the grinding table 21 by th...

Embodiment 3

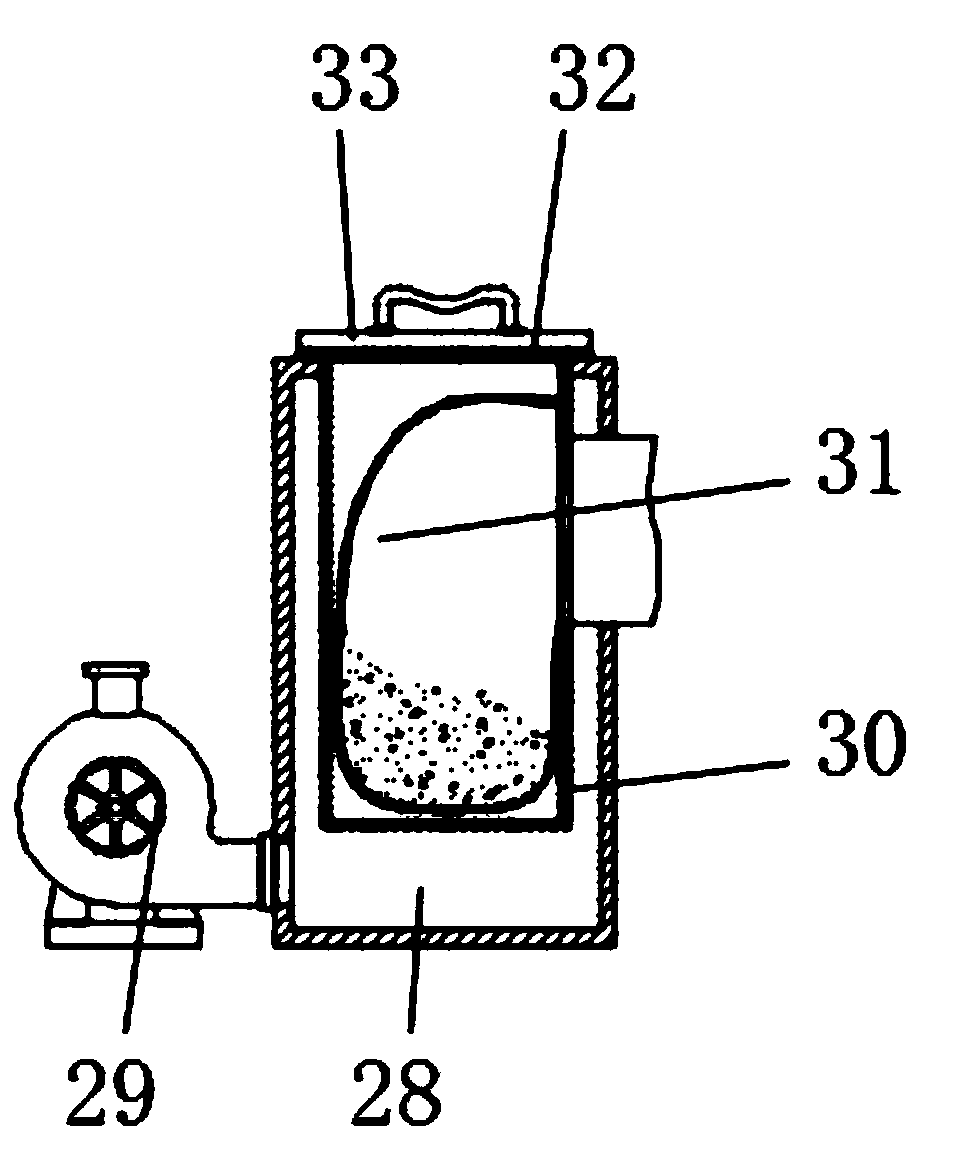

[0034] Embodiment three, refer to Figure 1-3, the bottom of the grinding chamber 11 is located inside the equipment body 1 and is provided with an exhaust pipe 27, and one side of the exhaust pipe 27 extends out of the equipment body 1 to connect with one side of the dust box 28, and the other side of the dust box 28 is connected to the exhaust fan 29 connection, the inside of the dust collection box 28 is provided with a hand basket 30, and the top of the hand basket 30 is provided with an upper end cover 33, and a sealing gasket 32 is provided between the upper end cover 33 and the dust collection box 28, and the hand basket 30 is a hollow mesh structure, And hand basket 30 interiors are provided with dust collection cloth bag 31, and dust collection cloth bag 31 sacks are corresponding with exhaust duct 27 air inlets, and one side of polishing storehouse 11 is positioned at the top of polishing table 21 and is fixed with a plurality of air blowers 12 by bracket installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com