Multi-station adjustable pneumatic plastic pin machine

An adjustable, glue needle machine technology, applied in the field of pneumatic glue needle guns, can solve the problems of not being able to adjust the distance and height of glue needle guns very freely, large power loss of the driving cylinder, and low accuracy, so as to reduce vibration , Reduce the installation space, increase the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

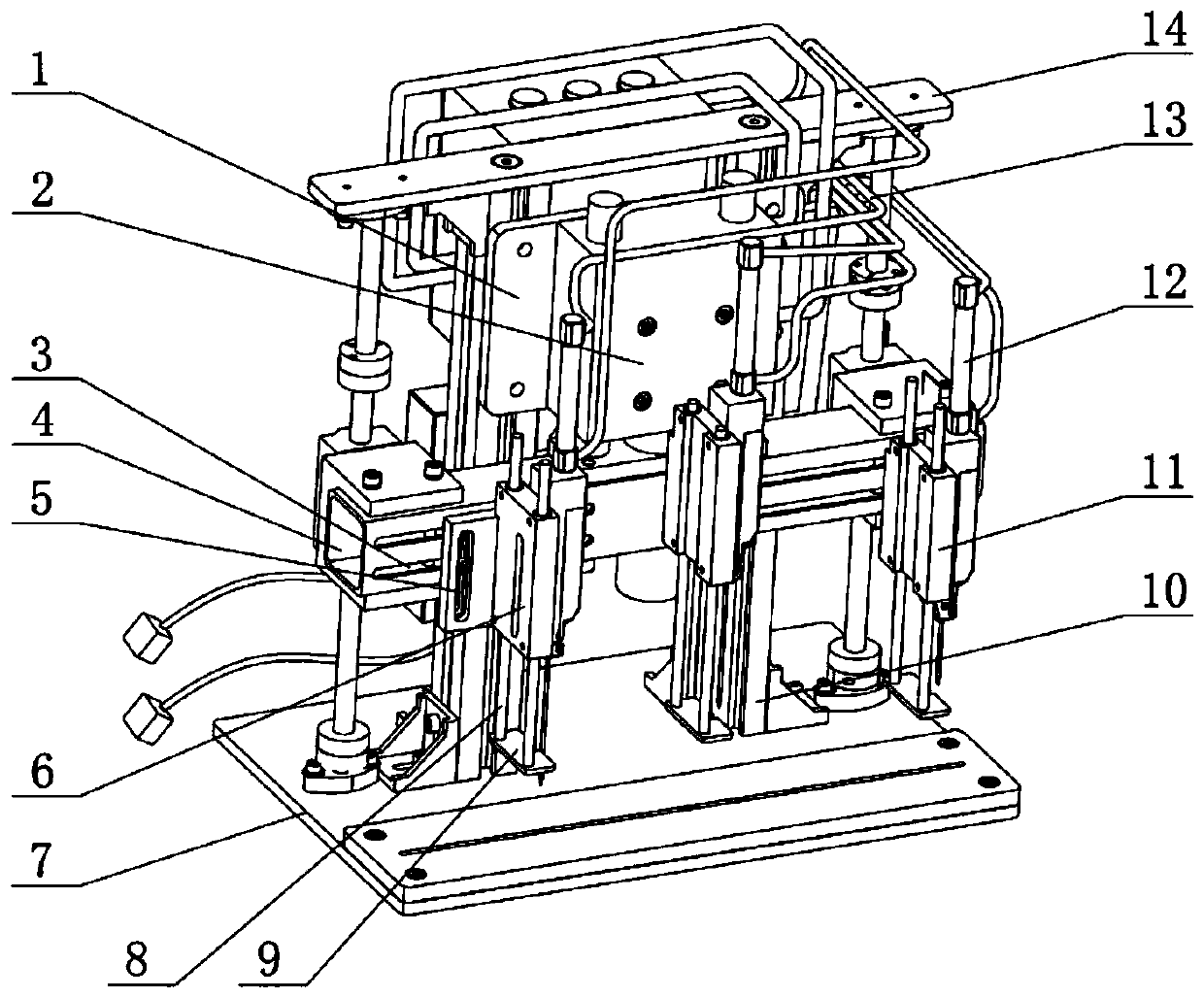

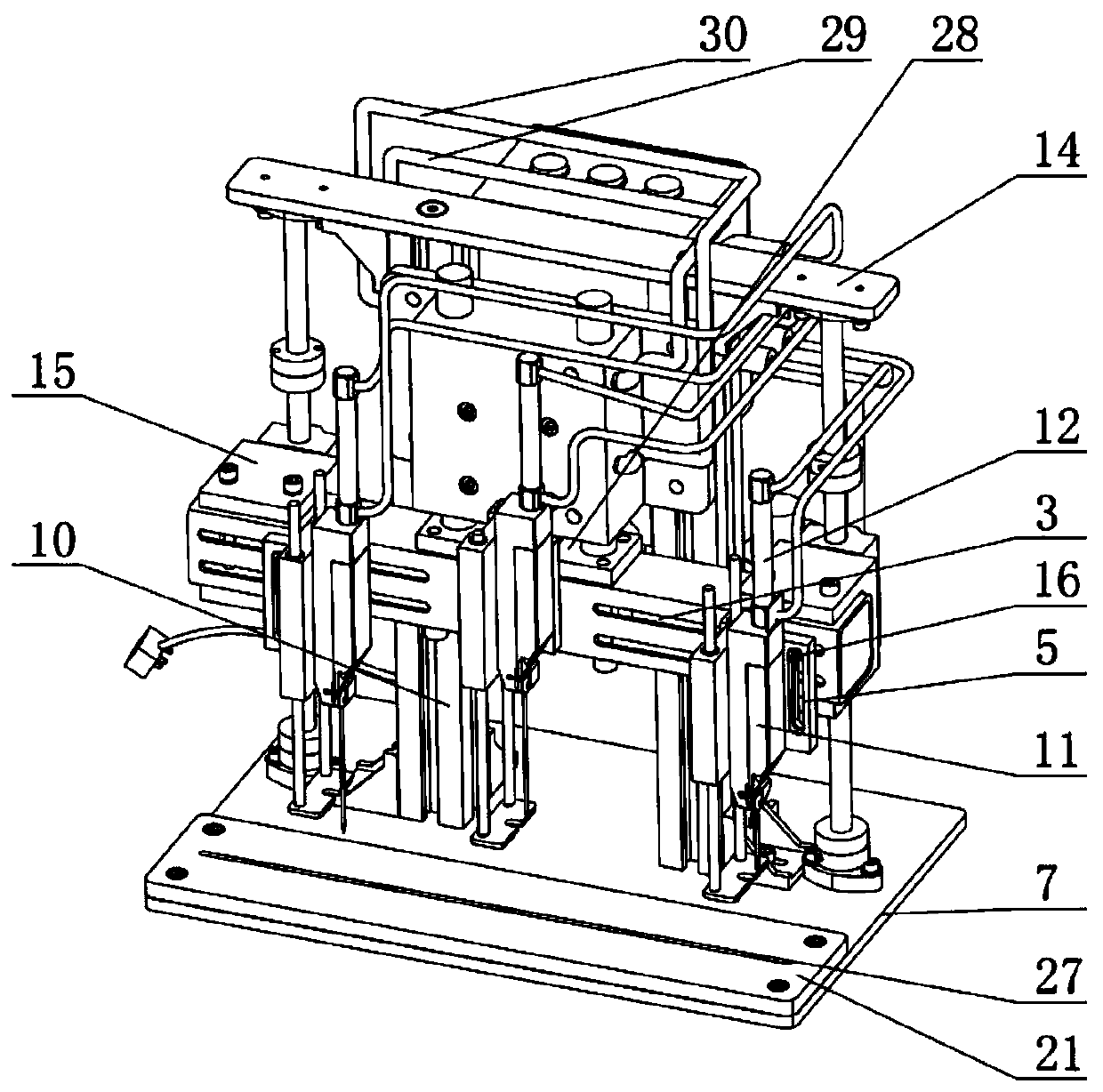

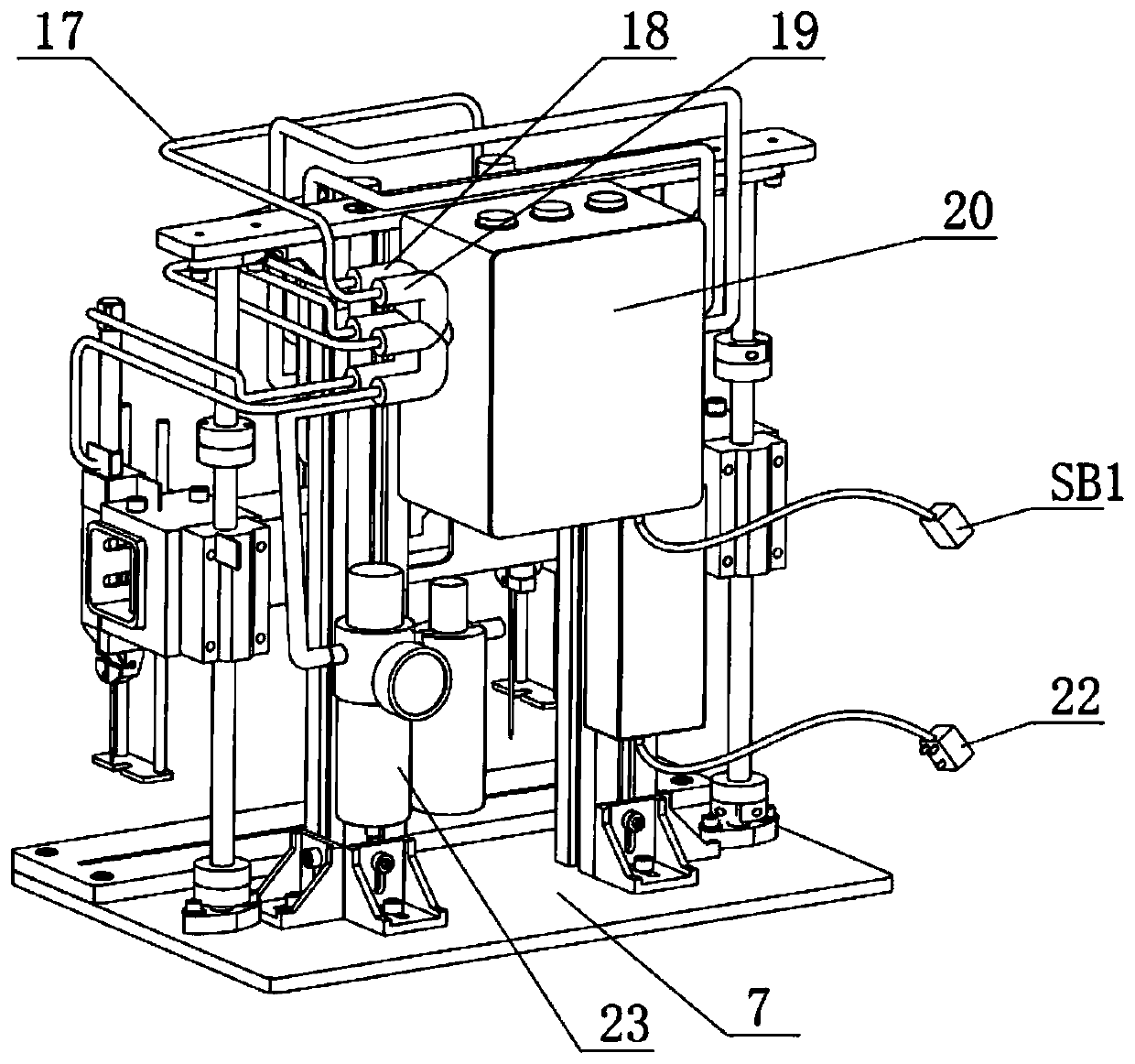

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1-4 As shown, a multi-station adjustable pneumatic glue needle machine includes a base 7, a support frame assembly, a downward pressure cylinder 2, a pneumatic glue needle gun station and an air pipe, and the support frame assembly is located on the On the base 7, there are multiple pneumatic glue needle gun stations, which are movably fixed on the support frame assembly. The pneumatic glue needle gun stations include the presser foot 9 assembly and the pneumatic glue needle gun 11. The pneumatic glue needle gun 11 is connected with a glue needle cylinder 12, and the downward pressure cylinder 2 simultaneously drives a plurality of pneumatic glue needle gun stations to move up and down, and the glue needle cylinder 12 realizes the glue needle action.

[0029] In this embodiment, the support frame assembly includes a main body sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com