Bidirectional cutting device of a cutting machine

A technology of cutting device and cutting machine, which is applied in the direction of sawing machine, metal processing equipment, metal sawing equipment, etc., can solve the problems of not being able to meet the needs of users, poor structural matching performance, and affecting efficiency, so as to improve the external connection performance, improved adjustment convenience, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

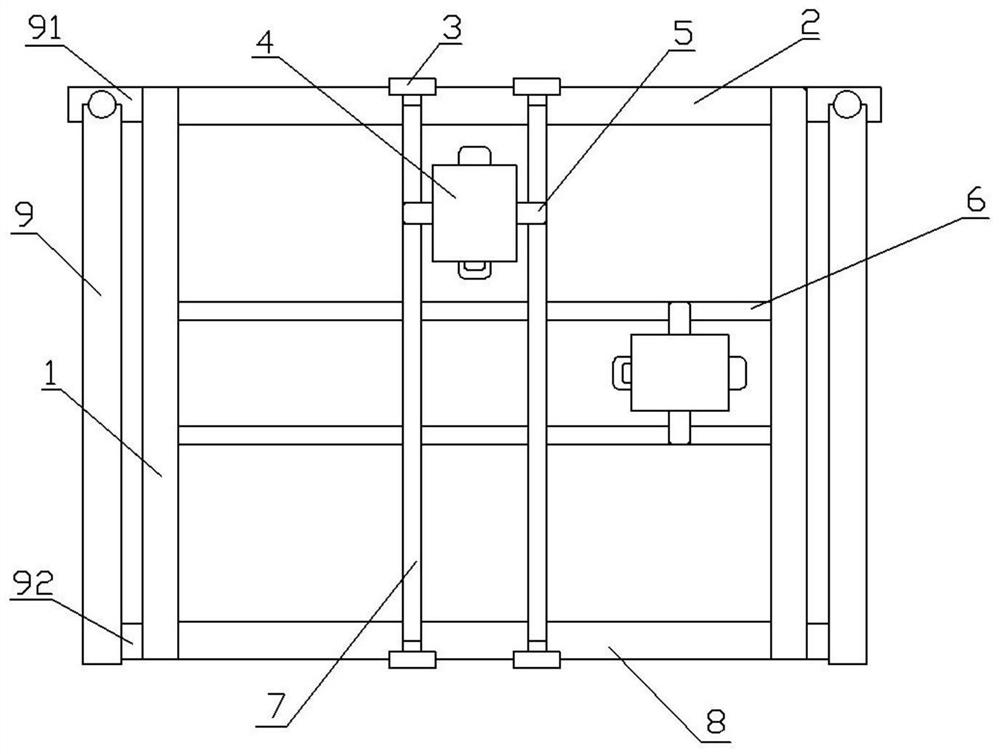

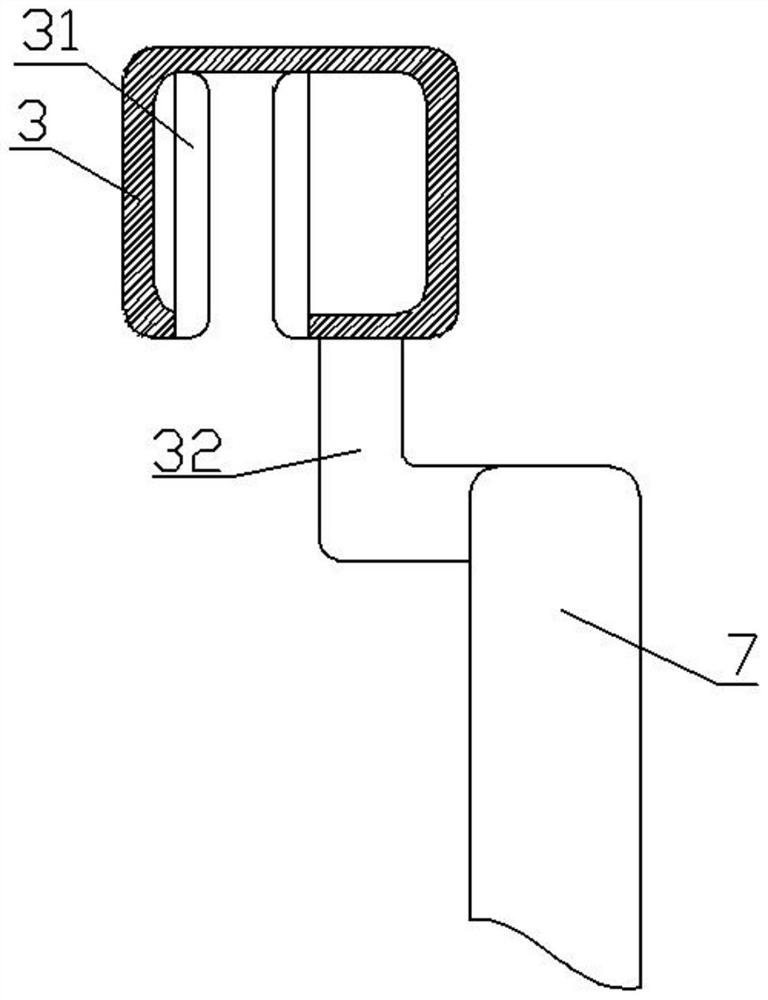

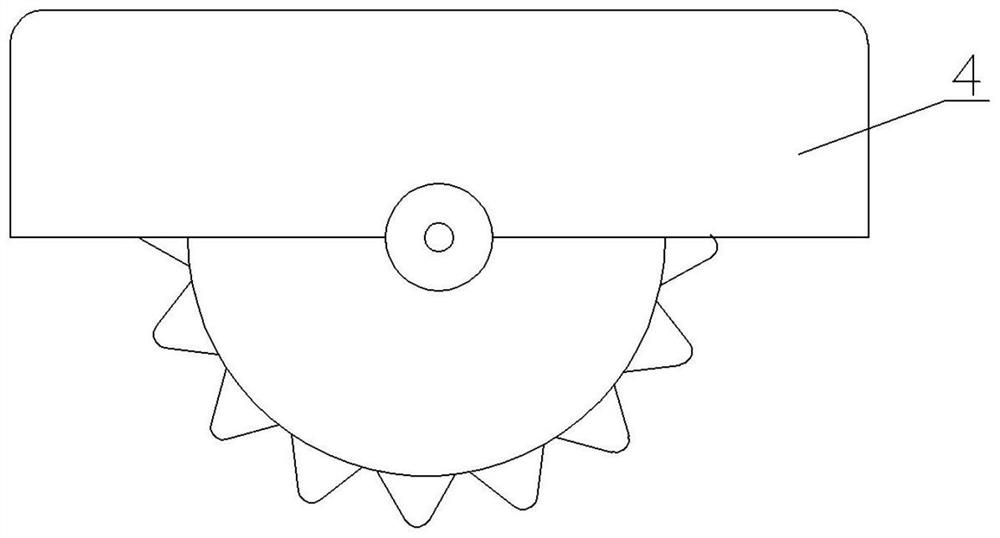

[0024] as attached figure 1 to attach Figure 4 shown

[0025] The invention provides a two-way cutting device for a cutting machine, which includes a fixed plate 1, an upper end fixed structure 2, an adsorption head 3, an electric saw disc 4, a claw 5, a horizontal slide rail 6, an electric slide rail 7, and a ground edge 8 and a stable edge 9, one side of the fixed plate 1 is provided with a stable edge 9, and the upper end of the fixed plate 1 is provided with an upper end fixed structure 2, and the surface of the upper end fixed structure 2 is provided with an adsorption head 3; the adsorption head 3 The lower end of the electric slide rail 7 is provided with a claw 5 on the surface of the electric slide rail 7, and the upper surface of the claw 5 is provided with an electric saw disc 4; the lower end of the electric slide rail 7 is connected with a solid edge 8 , and the bottom of the electric slide rail 7 is provided with a horizontal slide rail 6; the suction head 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com