Cargo carrying table with novel anti-falling mechanism and method thereof

A loading platform and anti-drop technology, applied in the direction of mechanical equipment, brake types, storage devices, etc., can solve the problems of safety accidents, injuries, breakages, etc., and achieve the effect of avoiding safety accidents and significant protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

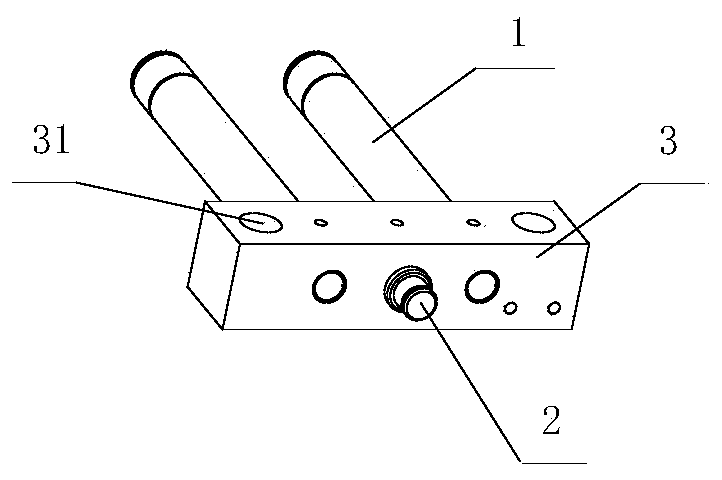

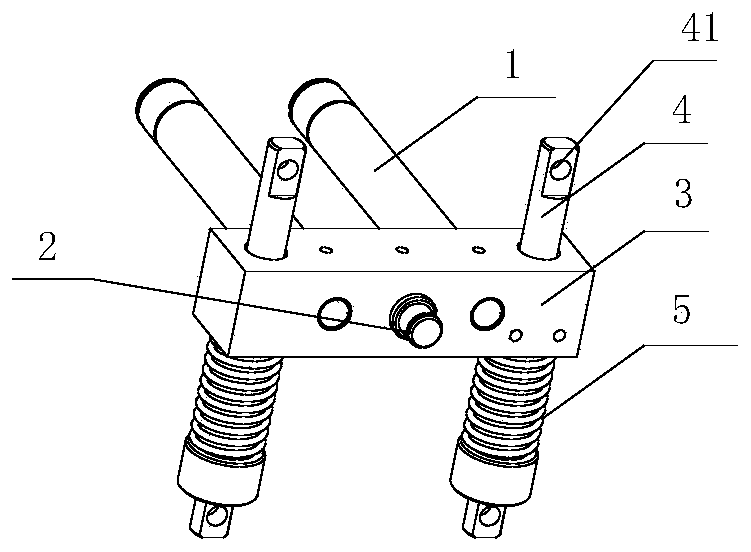

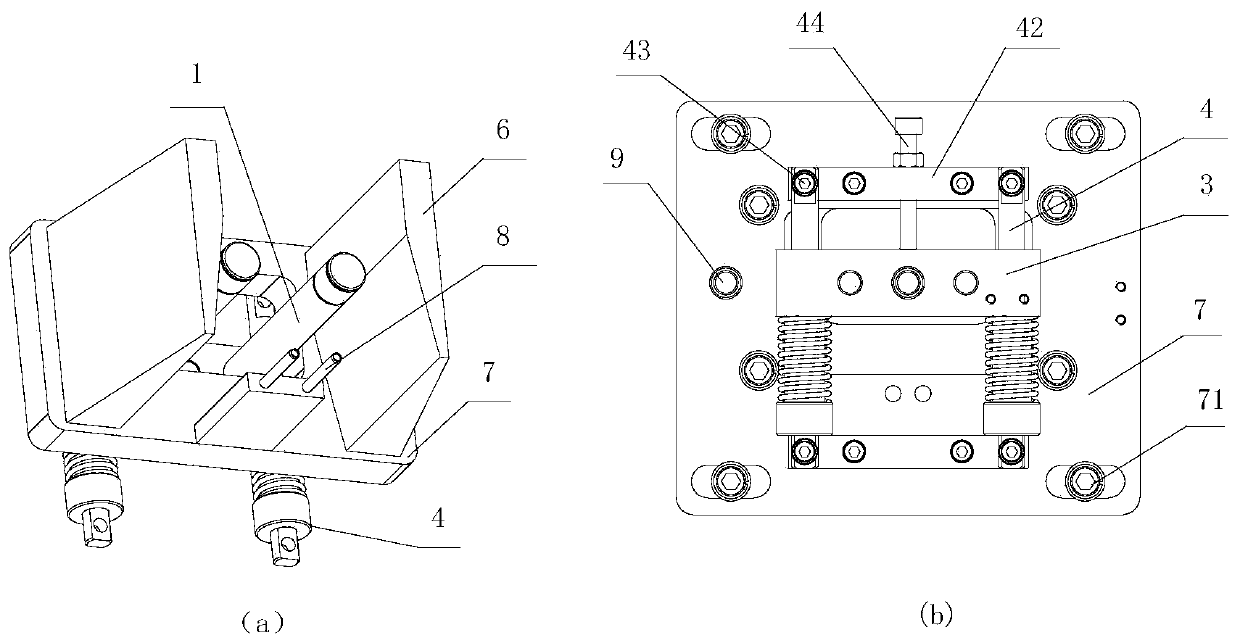

[0031] Example 1, as Figure 1 to Figure 8 As shown, the cargo platform with the novel anti-fall mechanism of the present application mainly includes anti-fall guide rails 16 and a lifting anti-fall device connected to the carrier 13 of the cargo platform.

[0032] Specifically, the lifting and anti-falling device is installed on the side arm 100 of the cargo platform, and includes a lever 12 whose one end is connected to the cargo platform carrier 13, and the other end of the lever 12 is connected to the spindle 2 of the slider 3, which is connected to the core A set of connecting rod shafts 1 are arranged on the slider 3 in the opposite direction of the shaft 2; over and support lever 12;

[0033] A set of guide posts 4 are vertically penetrated and installed on the slider 3, and the guide posts 4 are sleeved with a return spring 5; the vertical sides of the slider 3 and the return spring 5, and the upper and lower shaft ends of the connecting rod shaft 1 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com