A sic with co-deposited multiphase interface f /sic composite material preparation method

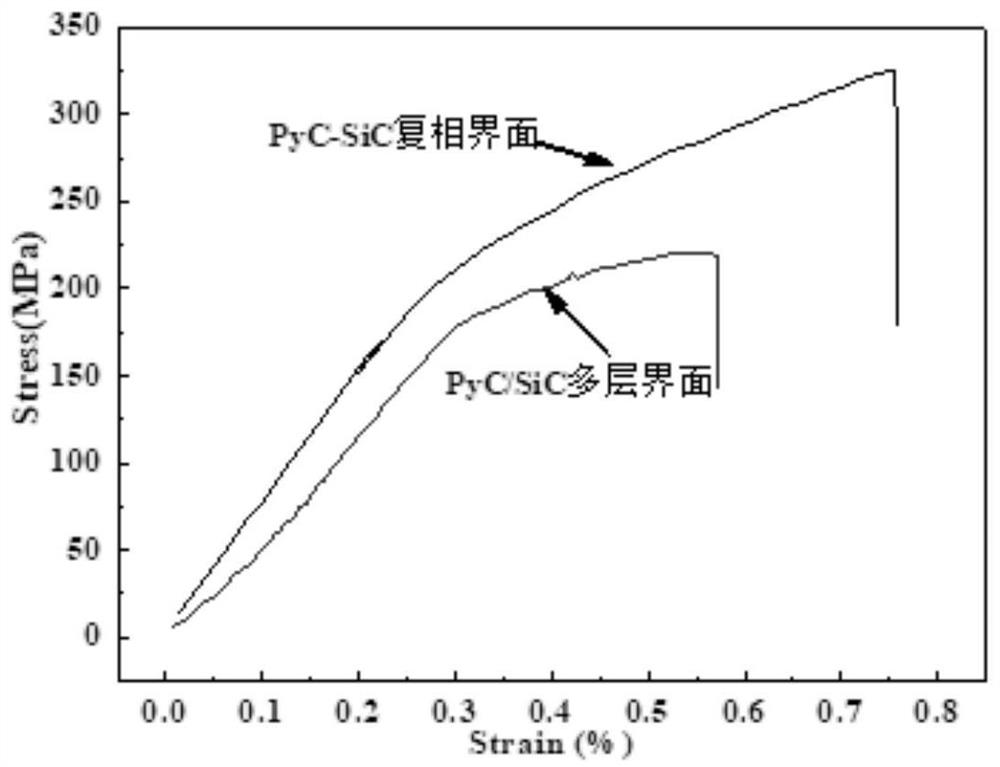

A composite material and phase interface technology, which is applied in the field of nuclear industry composite materials, can solve the problems of low toughening efficiency and difficult control of multi-layer interfaces, and achieve the effects of easy control of preparation, improvement of strength and toughness, and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

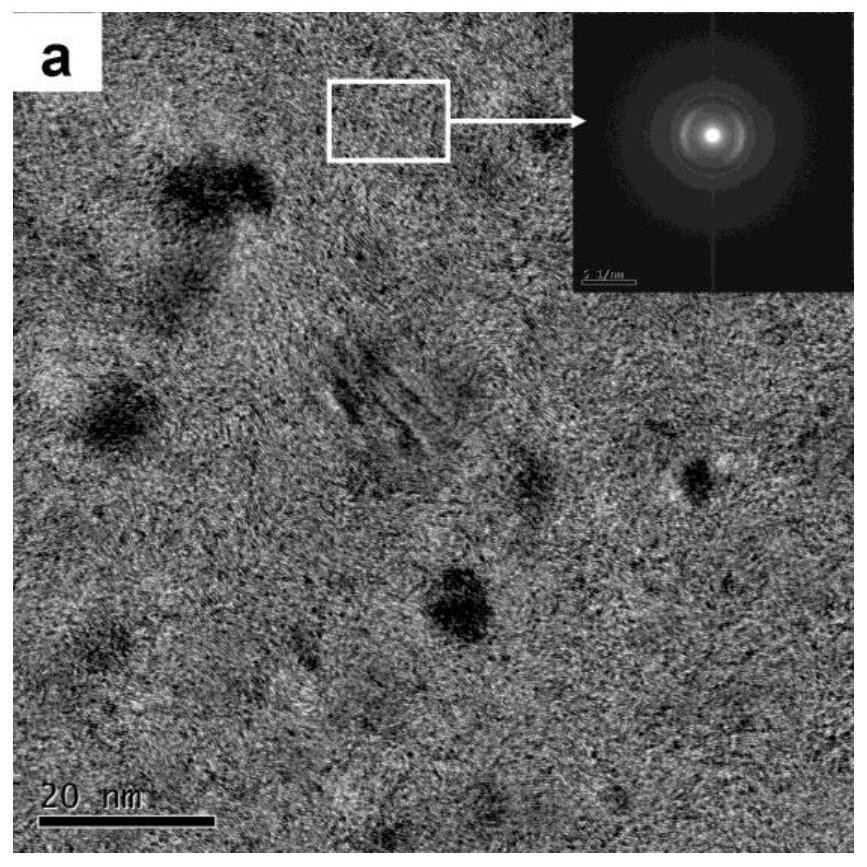

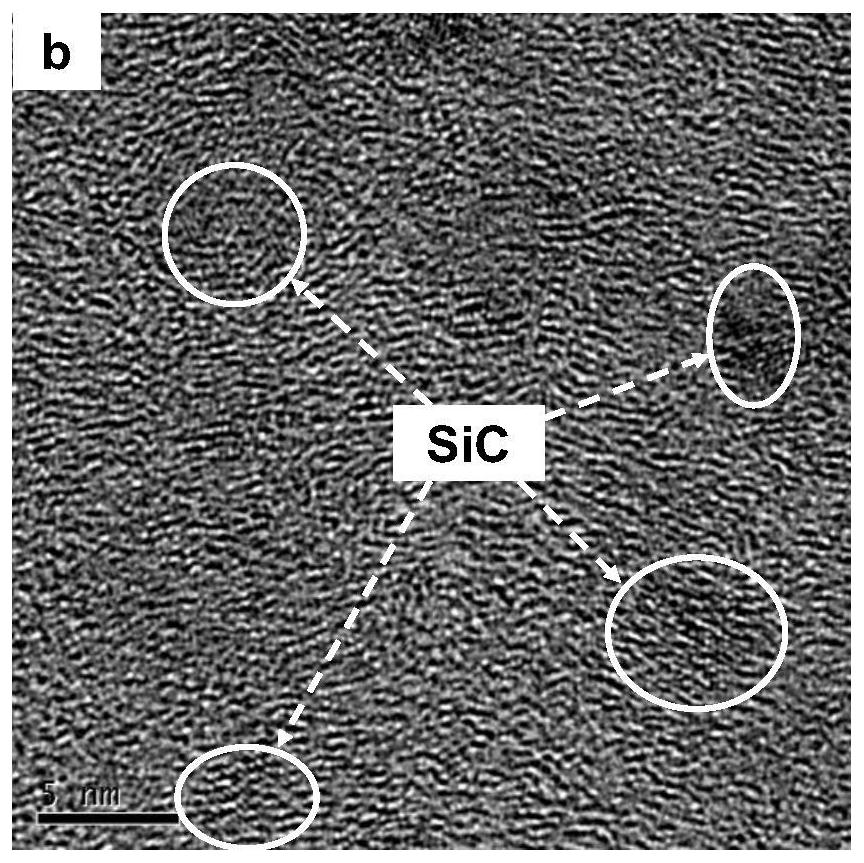

[0023] Preparation of SiC with PyC-SiC Multiphase Interface f / SiC composite material, the specific preparation method is:

[0024] Step 1, prepare the SiC fiber preform: use the SiC fiber to weave the composite material preform to obtain the SiC fiber preform that meets the required structural form of the sample;

[0025] Step 2, interface deposition: place the SiC fiber preform in a chemical vapor deposition furnace to start co-deposition to obtain a multiphase interface. The reaction gas system used is: SiCl 3 CH 3 -H 2 -C 3 h 6 - Ar, SiCl 3 CH 3 Used as SiC source gas, C 3 h 6 As a carbon source gas, the flow ratio of propylene to carrier gas hydrogen is 5, the flow ratio of diluted hydrogen to carrier gas hydrogen is 4, the flow ratio of diluted argon to diluted hydrogen is 2, the deposition temperature is 1000 °C, and the deposition pressure is 100 ~150Pa, deposition time is 40~45min;

[0026] Step 3: Place the SiC fiber prefabricated body with the prepared mul...

Embodiment 2

[0028] Preparation of SiC with PyC-SiC Multiphase Interface f / SiC composite material, the specific preparation method is:

[0029] Step 1, prepare the SiC fiber preform: use the SiC fiber to weave the composite material preform to obtain the SiC fiber preform that meets the required structural form of the sample;

[0030] Step 2, interface deposition: place the SiC fiber preform in a chemical vapor deposition furnace to start co-deposition to obtain a multiphase interface. The reaction gas system used is: SiCl 3 CH 3 -H 2 -C 3 h 6 - Ar, SiCl 3 CH 3 Used as SiC source gas, C 3 h 6 As a carbon source gas, the flow ratio of propylene to carrier gas hydrogen is 7, the flow ratio of diluted hydrogen to carrier gas hydrogen is 6, the flow ratio of diluted argon to diluted hydrogen is 4, the deposition temperature is 950 °C, and the deposition pressure is 250 ~300Pa, the deposition time is 50~55min;

[0031] Step 3: Place the SiC fiber prefabricated body with the prepared ...

Embodiment 3

[0033] Preparation of SiC with PyC-SiC Multiphase Interface f / SiC composite material, the specific preparation method is:

[0034] Step 1, prepare the SiC fiber preform: use the SiC fiber to weave the composite material preform to obtain the SiC fiber preform that meets the required structural form of the sample;

[0035] Step 2, interface deposition: place the SiC fiber preform in a chemical vapor deposition furnace to start co-deposition to obtain a multiphase interface. The reaction gas system used is: SiCl 3 CH 3 -H 2 -C 3 h 6 - Ar, SiCl 3 CH 3 Used as SiC source gas, C 3 h 6 As a carbon source gas, the flow ratio of propylene to carrier gas hydrogen is 10, the flow ratio of diluted hydrogen to carrier gas hydrogen is 9, the flow ratio of diluted argon to diluted hydrogen is 5, the deposition temperature is 1200 °C, and the deposition pressure is 850 ~900Pa, the deposition time is 55~60min;

[0036] Step 3: Place the SiC fiber prefabricated body with the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com