Rail summer cooling device

A cooling device and rail technology, applied in the field of rail transit, can solve the problems of casualties, train derailment, rail distortion, etc., and achieve the effects of increasing utilization, reducing impact force, and facilitating watering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

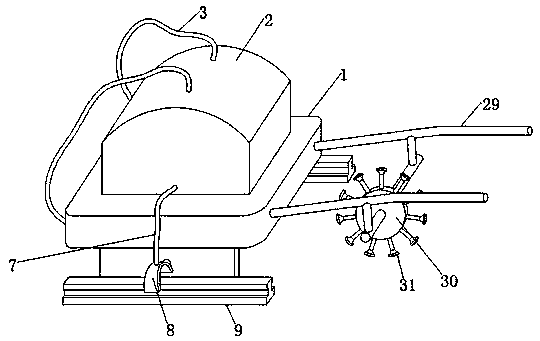

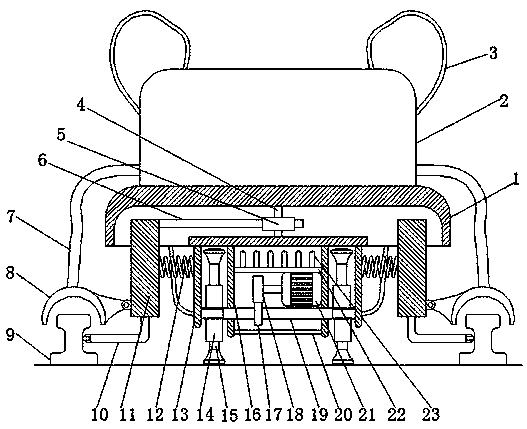

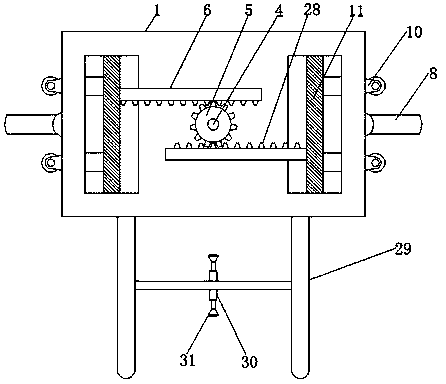

[0029] refer to Figure 1-4 , a rail summer cooling device, comprising a main body 1 between two rails 9, the top of the main body 1 is bonded with a water tank 2, both sides of the bottom of the main body 1 are provided with a moving plate 11, one side of the moving plate 11 A water outlet body 8 is rotatably connected, and a water delivery pipe 7 is connected between the top of the water outlet body 8 and the water tank 2. The water outlet body 8 is above the rail 9, and the water in the water tank 2 can enter the water outlet body 8 through the water delivery pipe 7. The main body The bottom end of 1 is welded with two first fixed plates 13 and two second fixed plates 16, and a rotating rod 19 is connected between the two first fixed plates 13, and the middle part of the second fixed plate 16 is provided with a circular opening hole, the rotating rod 19 runs through the second fixed plate 16 at the circular through hole, the two ends of the rotating rod 19 are welded with t...

Embodiment 2

[0041] refer to Figure 5 , a rail summer cooling device. Compared with Embodiment 1, in order to increase the practicability of the device, the amount of sprayed water can be controlled according to the surface temperature of the rail 9. One side of the water outlet body 8 is provided with infrared temperature measurement. Instrument 32, the junction of water outlet body 8 and water delivery pipe 7 is provided with electromagnetic valve 33, and infrared thermometer 32 can control electromagnetic valve 33 according to the difference of rail 9 surface temperature, changes water spray volume.

[0042] When in use, push the device between the rails 9, the moving plate 24 will contact the rails 9, the arc-shaped structure will prevent the device from sliding when passing on the rails 9, causing the device to be stuck, and the moving plate 24 will drive the second moving rod 25 to compress The second spring 26, the second spring 26 and the sponge can reduce the impact force of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com