Filtering device and filtering method for hydrates of surface pipeline of well site of natural gas well

A technology for surface pipelines and hydrates, which is applied to wellbore/well valve devices, wellbore/well components, and earth-moving drilling and production, etc., can solve the problems of increasing the difficulty of gas well management and maintenance and the consumption of manpower and material resources, and save manpower. The effect of material resource consumption, reduction of maintenance difficulty, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

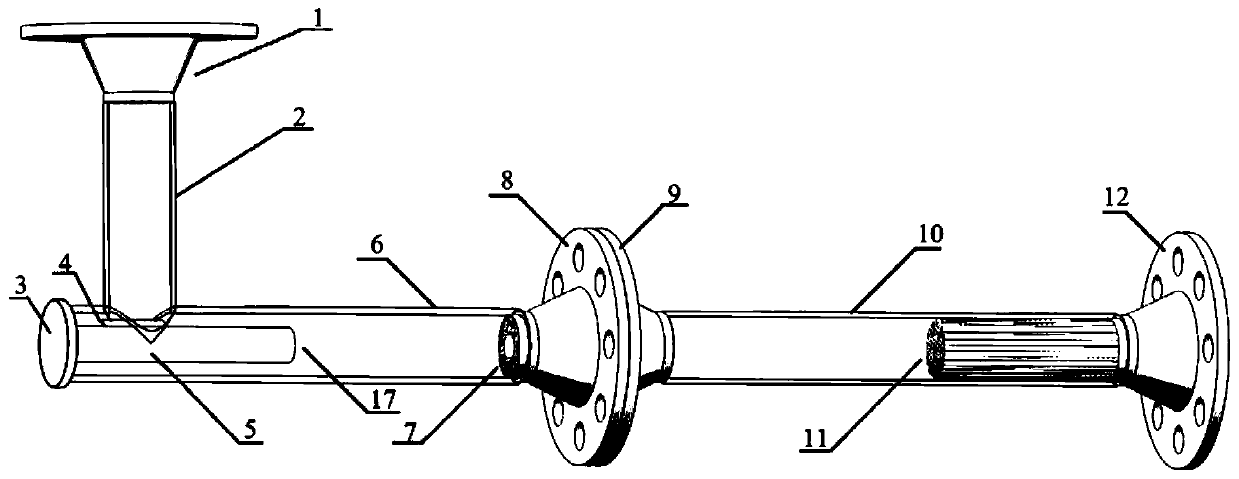

[0047] Please refer to figure 1 A natural gas well site surface pipeline hydrate filtering device according to the present invention includes a vortex generating part 17 whose front end is perpendicular to the air intake direction, a middle primary filter disc 7 and a rear hydrate filtering part 11; the front vortex generating part 17 and The middle-end primary filter discs are respectively located at both ends of the middle oil pipe 6, and are connected to the lower oil pipe 10 through the lower flange 8 of the middle oil pipe and the upper flange 9 of the lower oil pipe 10; .

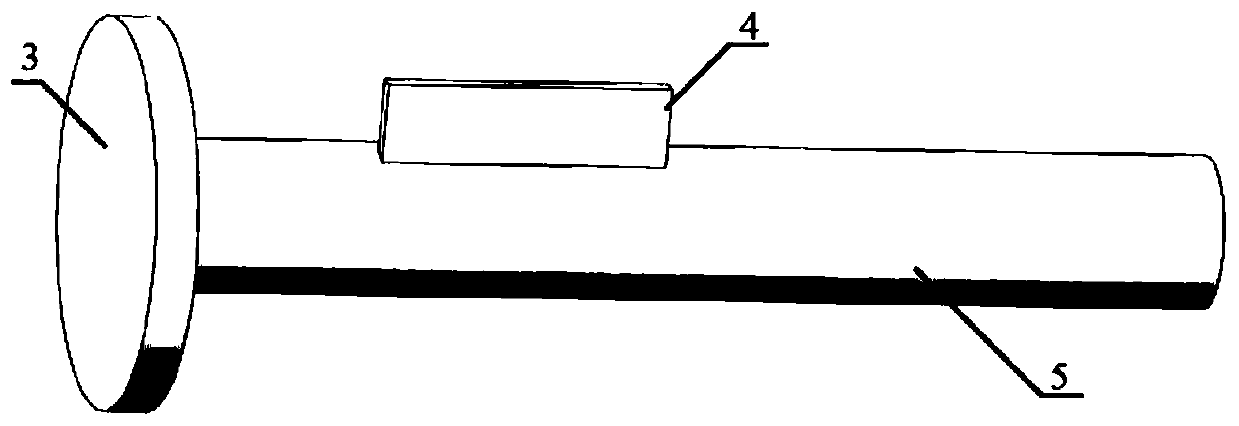

[0048] Please refer to figure 2 The eddy current generating part 17 includes a spin rod 5, an end blind plate 3, and a deflector 4; the spin rod 5 is concentrically welded on the end blind plate 3, and the deflector 4 is welded on the spin rod 5 and is connected with the advance The included angle of the gas oil pipe axis is 50 degrees and points to the intake oil pipe 2 .

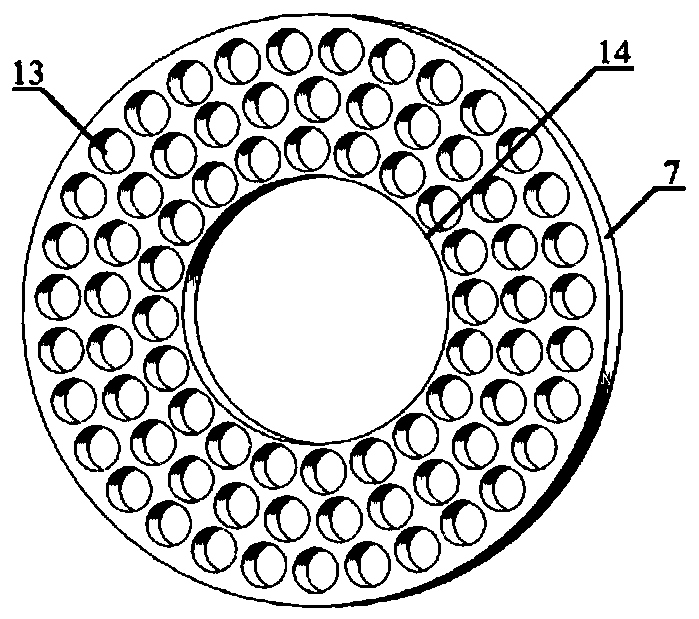

[0049] Please refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com