A bidirectional metering pump and liquid pumping method thereof

A technology for metering pumps and pump casings, applied in the field of bidirectional metering pumps and their pump fluids, can solve problems such as increasing the cost of hydraulic systems, achieve the effects of improving bidirectional metering accuracy, simplifying the driving structure, and overcoming the single direction of pump fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

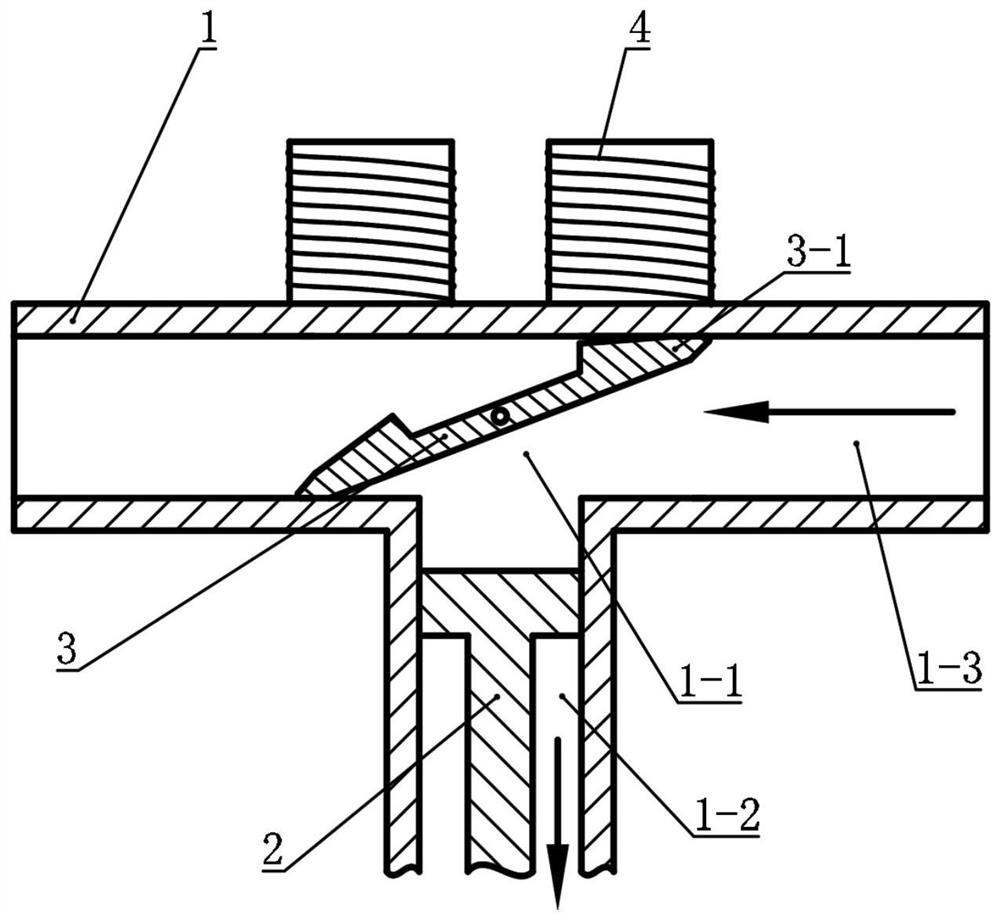

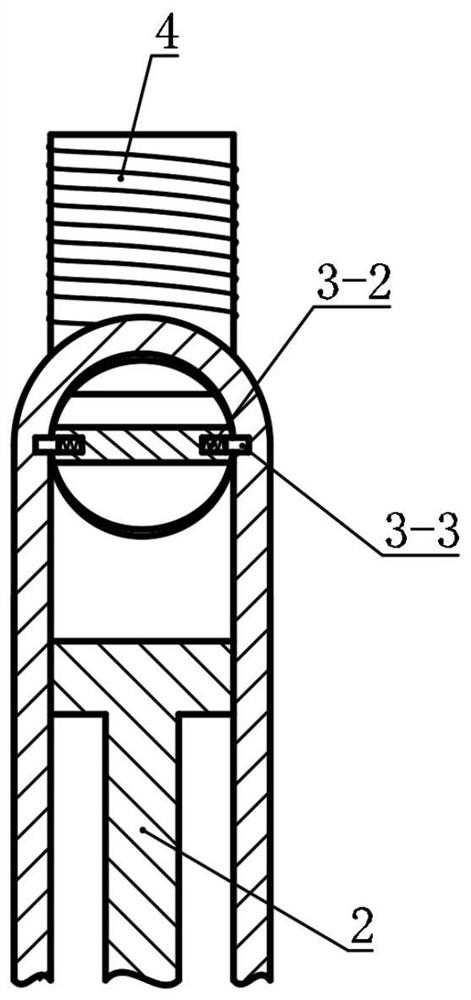

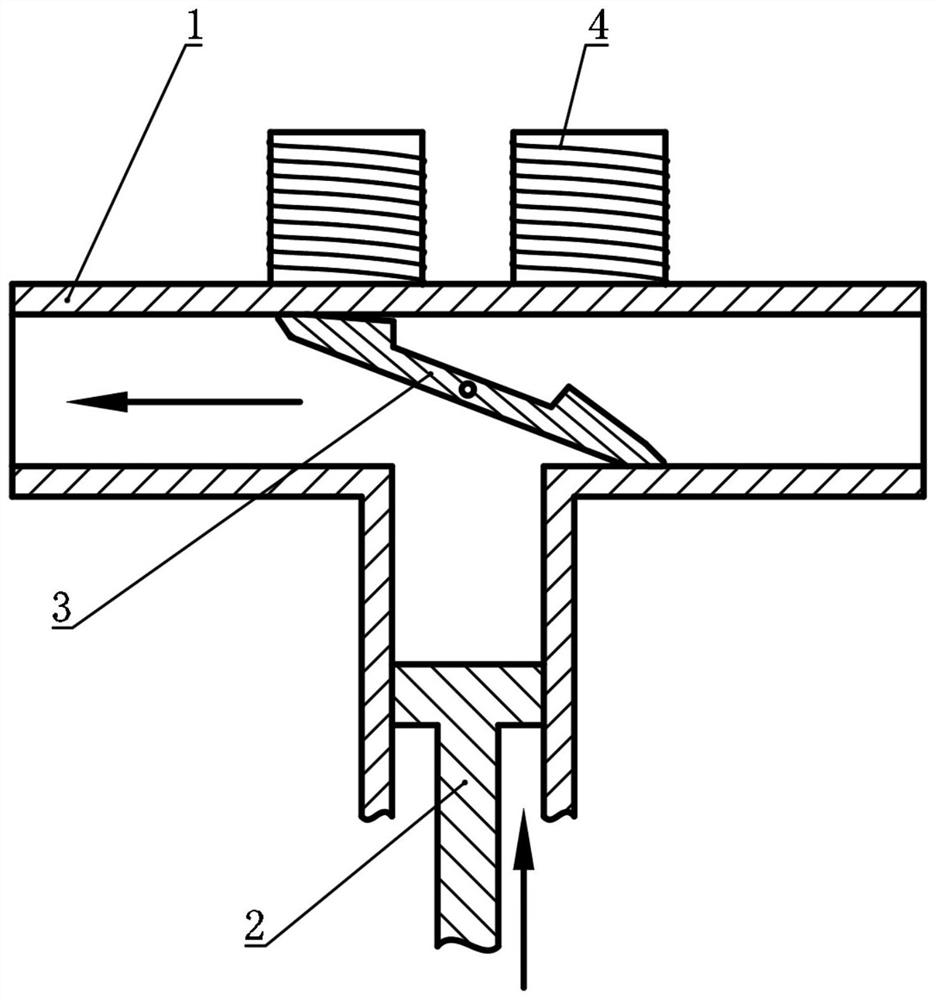

[0030] Such as figure 1 , 2 As shown in and 3, a two-way metering pump includes a pump housing 1, a piston rod 2, a switching plate 3, an electromagnet 4 and a piston drive assembly. The pump housing 1 is provided with a T-shaped flow channel. The T-shaped flow channel is composed of a connecting cavity 1-1, a piston cavity 1-2 and two unilateral flow channels 1-3. The inner ends of the piston chamber 1-2 and the two unilateral flow passages 1-3 are in communication with the connection chamber 1-1. The cross sections of the connecting cavity 1-1 and the two unilateral flow channels are all circular. The outer ends of the two unilateral flow channels 1-3 are respectively the two liquid ports of the bidirectional metering pump.

[0031] The piston rod 2 is arranged in the piston cavity 1-2, and forms a sliding pair with the piston cavity 1-2. The piston rod 2 is driven by a piston drive assembly. The piston drive assembly consists of a gear, rack and drive motor. The rack...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

[0049]Damping valves are provided at the outer ends of the two unilateral flow channels 1-3. When the switching plate 3 is overturned, there is a short period of one-end communication between the two single-side flow channels 1-3. At this time, if there is a pressure difference between the two hydraulic components, it will cause part of the hydraulic medium to form a flow path under the action of the pressure difference during the turning over of the switching plate 3, reducing the pumping accuracy of the metering pump. The damping valve can prevent the rapid change of the flow rate of the hydraulic medium, and the turning process of the switching plate 3 is faster; therefore, setting the damping valve can significantly reduce the aforementioned flow conditions and effectively improve the pumping accuracy.

Embodiment 3

[0051] The difference between this embodiment and embodiment 1 is:

[0052] The outer ends of the two unilateral flow channels 1-3 are provided with electromagnetic on-off valves. In steps 2 and 4, the electromagnetic on-off valves are both closed. Therefore, the flow of hydraulic medium during the turning over of the switching plate 3 is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com