Electromagnetic valve for realizing pressure adjusting through mechanical force transmission

A technology of pressure regulation and mechanical force, applied in the field of solenoid valves, can solve the problems of complicated overall structure of solenoid valves and increasing the overall manufacturing cost of solenoid valves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

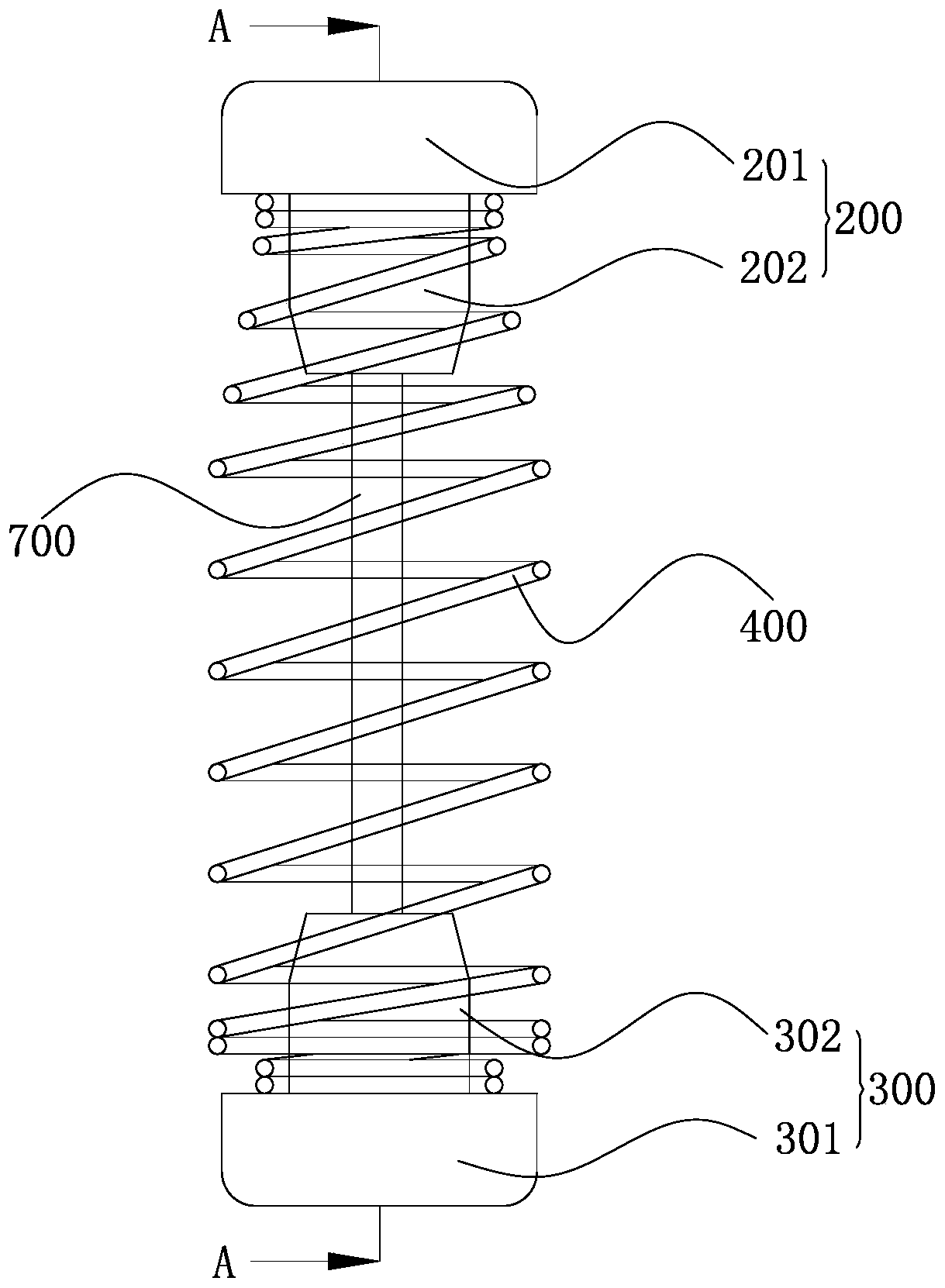

[0053] Implementation mode one: if Figure 5 As shown, the high-pressure exhaust plug 200 is provided with an air inlet cover sealing guide groove 203, the groove bottom of the air inlet cover sealing guide groove 203 is connected with the low-pressure air inlet hole 210, and the groove wall of the air inlet cover sealing guide groove 203 forms an inclined surface , The low-pressure air intake cap 500 is a conical frustum structure.

[0054] Similarly, the low-pressure intake plug 300 is provided with an exhaust cover sealing guide groove (not shown in the figure), the bottom of the exhaust cover sealing guide groove is connected with the high-pressure exhaust hole 310, and the groove wall of the exhaust cover sealing guide groove An inclined surface is formed, and the high-pressure exhaust cap 600 is a conical structure.

[0055] Like this, by setting up the air inlet cover seal guide groove 203, the groove wall of the air inlet cover seal guide groove 203 forms an inclined ...

Embodiment approach 2

[0056] Implementation mode two: if Figure 6 , Figure 7 and Figure 8 As shown, the high-pressure exhaust plug 200 is provided with an air intake cover sealing ring groove 204, and the air intake cover sealing ring groove 204 is arranged around the orifice of the low-pressure air intake hole 210. The sealing ring groove 204 matches the air intake cover sealing ring 501 .

[0057] Similarly, the low-pressure intake plug 300 is provided with an exhaust cover sealing ring groove (not shown in the figure), and the exhaust cover sealing ring groove is arranged around the opening of the high-pressure exhaust hole 310, and the high-pressure exhaust cap 600 is provided with The exhaust cover sealing ring (not shown) matched with the exhaust cover sealing ring groove.

[0058] In this way, when the low-pressure air intake cap 500 is closed on the low-pressure air intake hole 210, since the high-pressure exhaust plug 200 is provided with the air intake cover sealing ring groove 204,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com