Permanent magnet electromagnetic valve

A solenoid valve and permanent magnet technology, applied in the field of solenoid valves, can solve problems such as poor stability, small force, and complex structure, and achieve the effects of improving efficiency, increasing service life, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

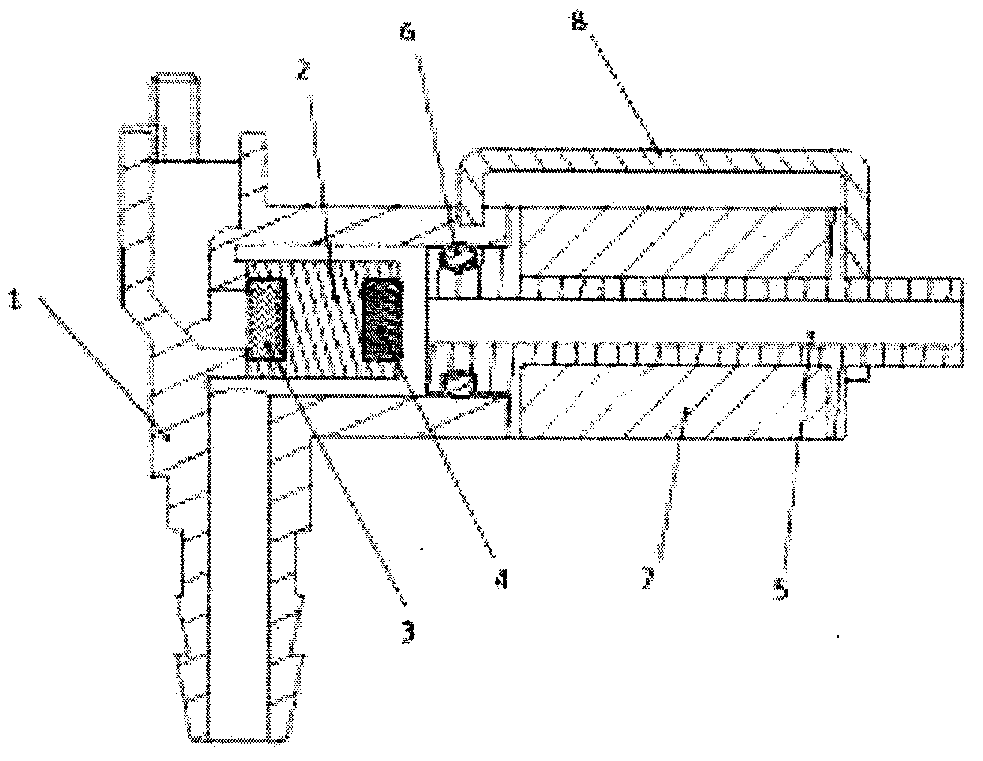

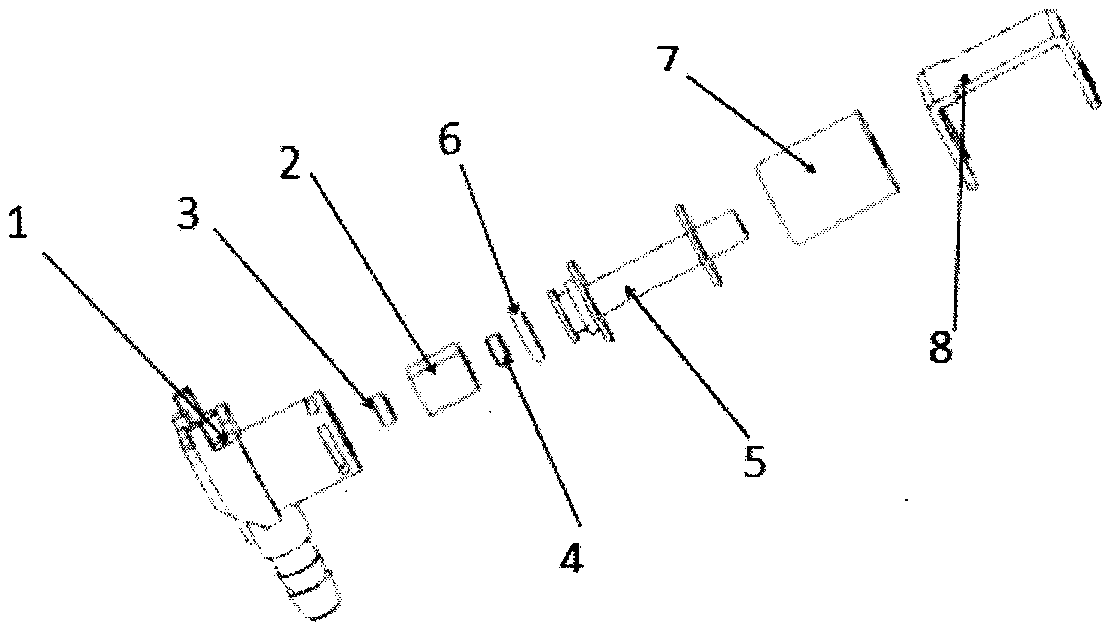

[0012] The structure of the permanent magnetic solenoid valve of the present invention is as figure 1 , figure 2 Shown, a kind of permanent magnet electromagnetic valve, it comprises valve body 1, permanent magnet spool 2 in valve body 1, left gasket 3 and right gasket 4 that permanent magnet spool 2 two ends are fixed, iron core 5 is connected on The valve body 1 and the sealing ring 6 are connected between the valve body 1 and the iron core 5, the iron core 5 is wound with a coil 7, and the iron cover 8 is connected to fix the iron core 5 and the valve body 1; when the coil 7 is energized, the iron core 5 generates Repel the electromagnetic force with the permanent magnet spool 2, push the permanent magnet spool 2 to move to the left to seal the valve port of the valve body 1 under the action of the repelling electromagnetic force, and open the valve port of the iron core 5 on the right; when the power supply of the coil 7 is disconnected, the iron The electromagnetic forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com