A hydraulic scale and its weighing method

A scale and hydraulic technology, applied in the field of hydraulic scale and its weighing, can solve the problems of large error and low sensitivity, and achieve the effect of reducing intermediate conversion links, high sensitivity, and reducing cumulative error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

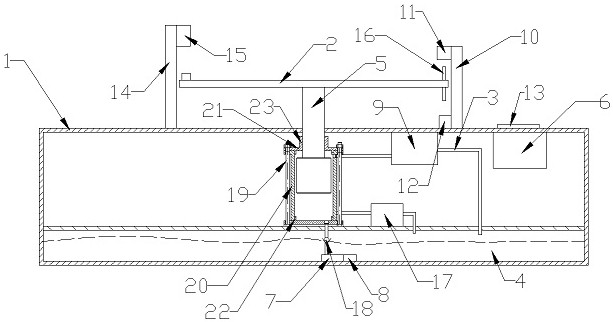

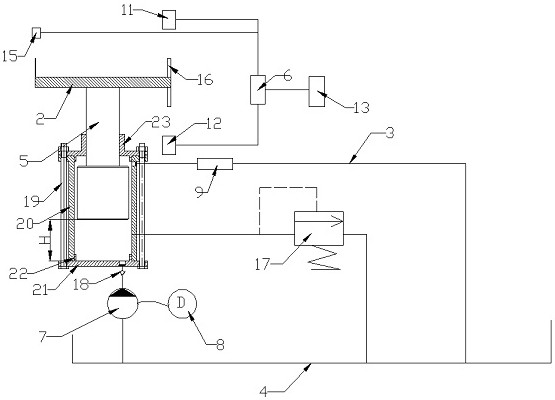

[0030] This embodiment, as the basic embodiment of the present invention, discloses a hydraulic scale, the specific structure is as follows figure 1 and figure 2 As shown, it includes a weighing body 1, which is provided with a pallet for carrying heavy objects; a hydraulic cylinder and an oil tank 4 are arranged in the weighing body 1, and the hydraulic cylinder is connected with the oil tank 4 through an oil delivery pipe 3, wherein the hydraulic pressure A hydraulic pump 7 is connected to the oil delivery pipe 3 on the inlet side of the cylinder, and the hydraulic pump 7 is connected to the drive motor 8. A shut-off valve 9 is arranged on the oil delivery pipe 3 on the outlet side of the hydraulic cylinder. There is a controller 6, and the weighing body 1 is also provided with a left bracket 14, the top and the bottom of the left bracket 14 are respectively provided with a first travel switch 11 and a second travel switch 12, and the input end of the controller 6 is connec...

Embodiment 2

[0032] As the best embodiment of the present invention, this embodiment discloses a hydraulic scale, the specific structure is as follows figure 1 and figure 2 As shown, it includes a weighing body 1, the weighing body 1 is provided with a pallet 2 for loading heavy objects; a hydraulic cylinder and a fuel tank 4 are arranged in the weighing body 1, and the hydraulic cylinder is connected with the fuel tank 4 through a fuel delivery pipe 3, A hydraulic pump 7 is connected to the oil delivery pipe 3 on the inlet side of the hydraulic cylinder, and the hydraulic pump 7 is connected to the drive motor 8, and a one-way valve 18 that opens to the hydraulic cylinder side is also arranged between the hydraulic pump 8 and the hydraulic cylinder. , the oil delivery pipe 3 on the outlet side of the hydraulic cylinder is provided with a shut-off valve 9, the said scale body 1 is also provided with a controller 6, the said scale body 1 is provided with a left bracket 14 and a right brack...

Embodiment 3

[0034] This embodiment, as another preferred embodiment of the present invention, discloses a weighing method of a hydraulic scale, which specifically includes the following steps:

[0035] A. Close the shut-off valve, start the drive motor and hydraulic pump to fill the hydraulic cylinder with hydraulic oil through the controller; after filling the hydraulic cylinder with sufficient hydraulic oil, control the drive motor to stop through the proximity switch and the controller;

[0036] B. Place the heavy object to be measured on the tray, and then start weighing through the controller, and the controller opens the stop valve;

[0037] C. After the piston rod moves to the bottom of the hydraulic cylinder, read the weight data of the item through the display screen;

[0038]D. After reading the data, take off the heavy object to be measured, and end the measurement through the controller. The controller closes the shut-off valve, and turns on the hydraulic pump to refill the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com