Full-automatic airtightness detection device and method for fuel cell stack

A fuel cell stack, a fully automated technology, applied in the direction of measuring the increase and decrease rate of the fluid, using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem of low standardization, no leak detection device, operability cumbersome and other problems, to achieve the effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

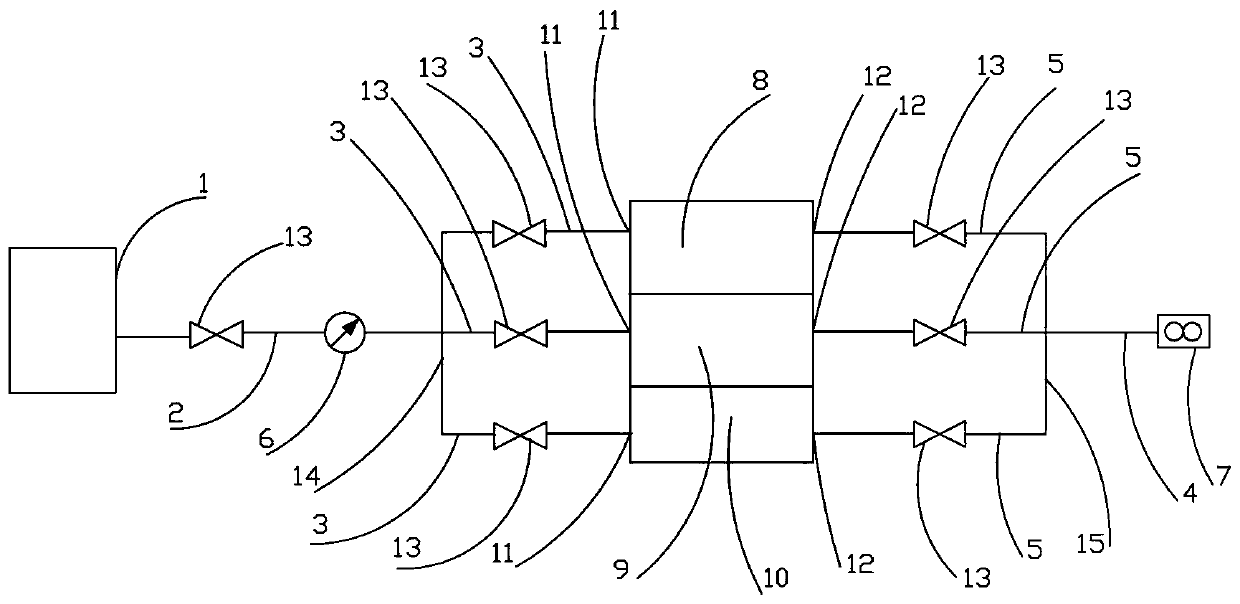

[0026] Such as figure 1 As shown, a fully automatic device for detecting the airtightness of a fuel cell stack of the present invention includes a gas storage bottle 1, a main air intake pipe 2, and three branch inlets that are all connected to the gas outlet end of the main air intake pipe 2. Air pipe 3, total outlet pipe 4, three outflow pipes 5, pressure detector 6 and gas flow meter 7 connected with the inlet end of total outlet pipe 4; , the three branch air pipes 3 communicate with the hydrogen chamber 8 of the fuel cell stack, the water chamber 9 and the air inlet 11 of the air chamber 10 respectively, and the three branch air pipes 5 respectively communicate with the hydrogen chamber 8, water chamber 8 and water chamber of the fuel cell stack. The air outlet 12 of the chamber 9 and the air chamber 10 is connected; the main air intake pipe 2, the three branch air pipes 3 and the three outflow air pipes 5 are all provided with a valve 13 to open or close it, and the pres...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that all the valves 13 involved in this embodiment can be electromagnetic valves in order to realize the function of automatic air tightness detection.

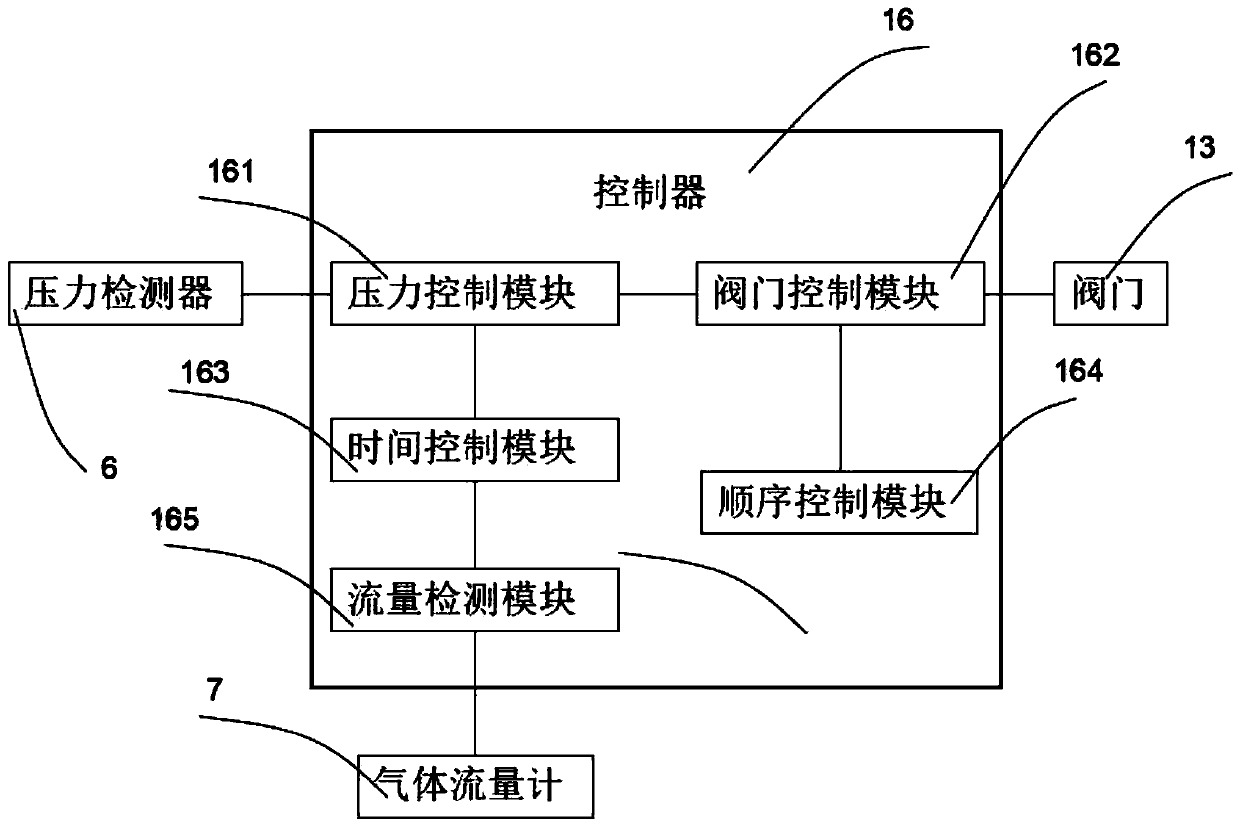

[0043] Such as figure 2 As shown, this embodiment may further include a controller 16, and all the solenoid valves 13, the pressure detector 6 and the gas flow meter 7 are electrically connected to the controller 16.

[0044] The controller 16 of this embodiment may include a pressure control module 161, a valve control module 162, a time control module 163, a sequence control module 164 and a flow detection module 165; The pressure control module 161 and the flow detection module 165 are electrically connected with the time control module 163; the valve control module 162 controls the opening and closing of the valve 13 by electrically connecting with all solenoid valves, and the pressure detector 6 will detect the The pressure value is transmitted to the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com