Quick-change mandrel having active preform clamping

A technology of preformed parts and clamping components, which is applied in the direction of household appliances, household components, and other household appliances, etc., can solve the problem of expensive replacement and transportation of mandrels, and achieve the effect of reliable replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Other advantages, features and characteristics of the present invention will become apparent in the following detailed description of embodiments with reference to the accompanying drawings. However, the present invention is not limited to these Examples.

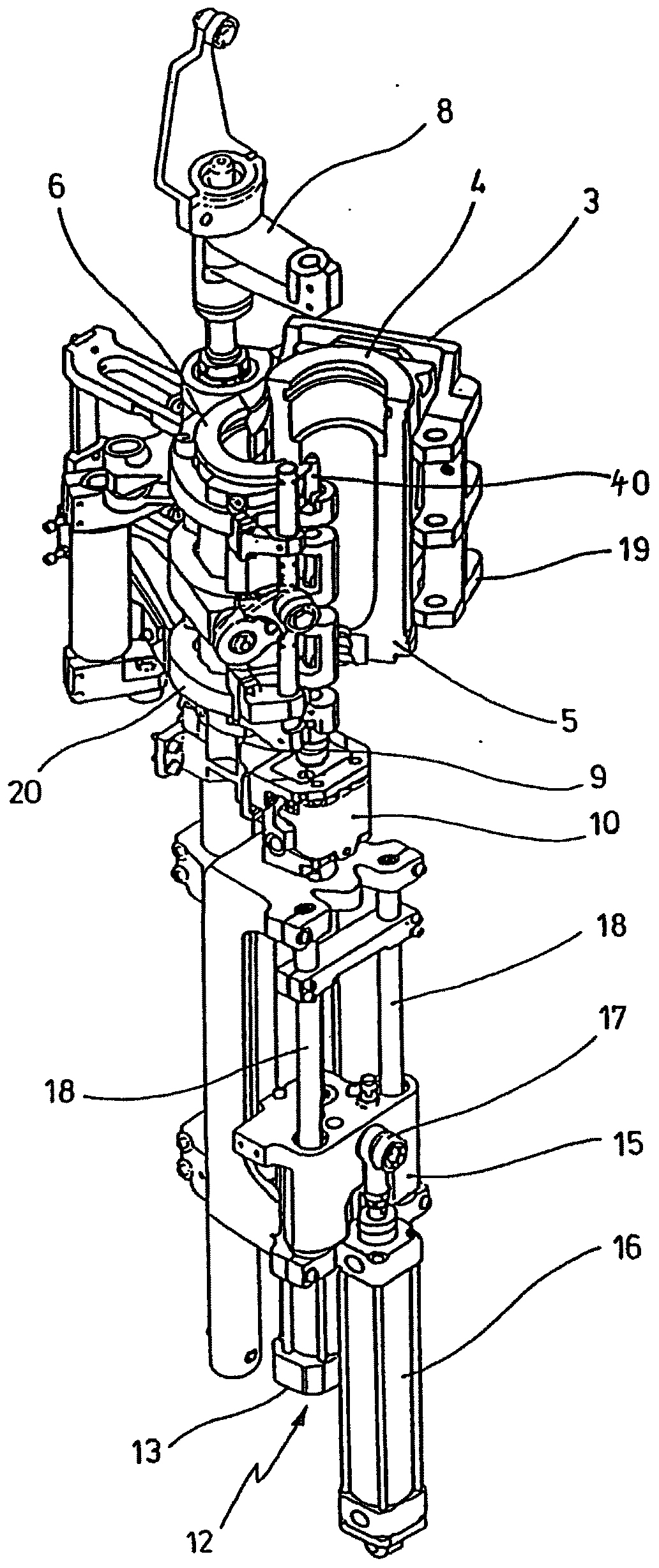

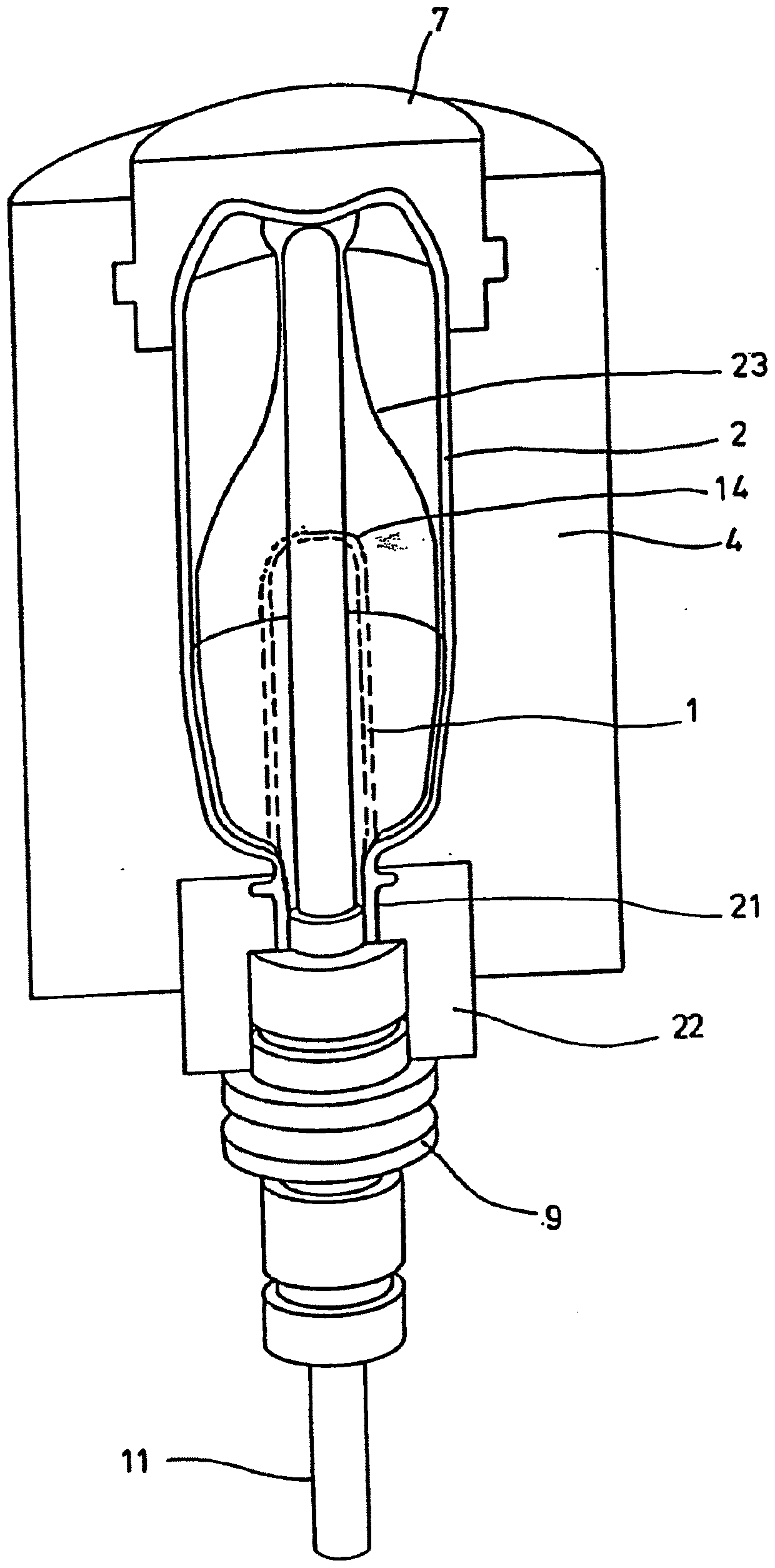

[0047] The principle structure of a device for forming a preform (1) into a container (2) is in figure 1 neutralize figure 2 shown in . The arrangement here can be realized as shown or rotated by 180° in the vertical plane.

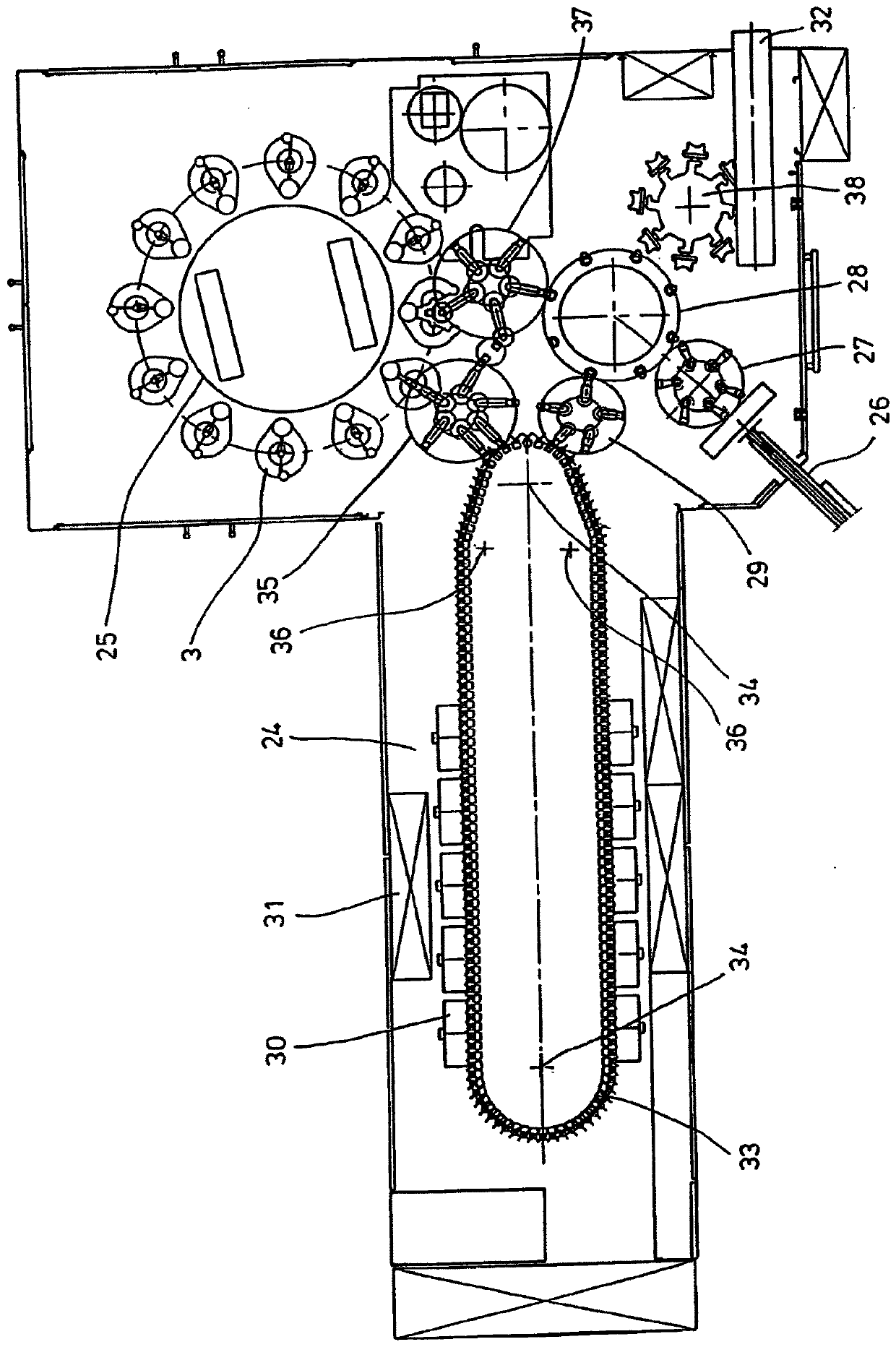

[0048] The plant for the shaping of the containers (2) essentially consists of a blow molding station (3) provided with blow molds (4) into which the preforms (1) can be placed . The preform (1) can be an injection molded part from polyethylene terephthalate. To enable the preform (1) to be placed into the blow mold (4) and to enable the removal of the finished container (2), the blow mold (4) comprises mold halves (5, 6) and a bottom part (7) , said bottom part can be positioned by a lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com