Cutting branch cutter

A technology for cutting branches and cutters, which is applied in the field of cutting branches cutters, can solve the problems that the quality cannot be guaranteed, the cutting work is affected, and the cuttings are easy to accumulate at the cutting knife, etc., and the advantages of simple structure, fast cutting and convenient operation are achieved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

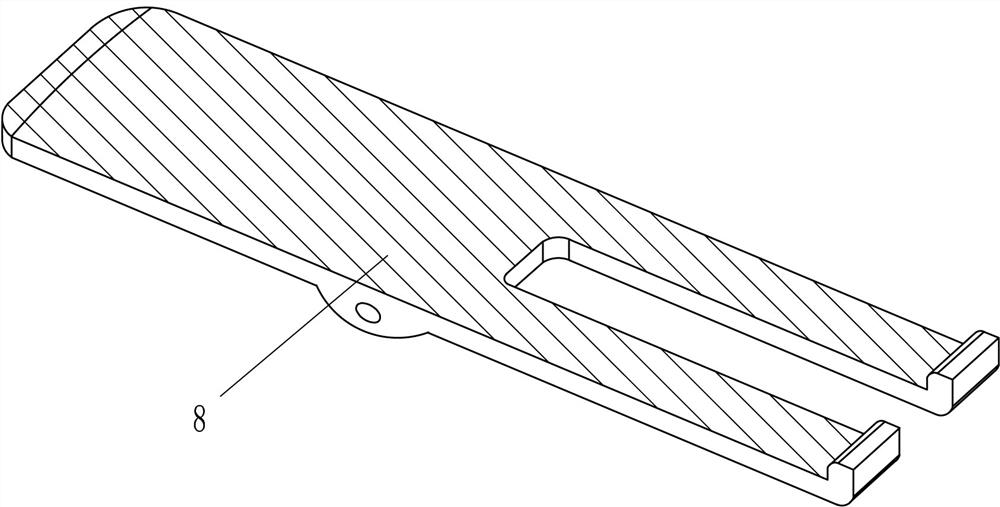

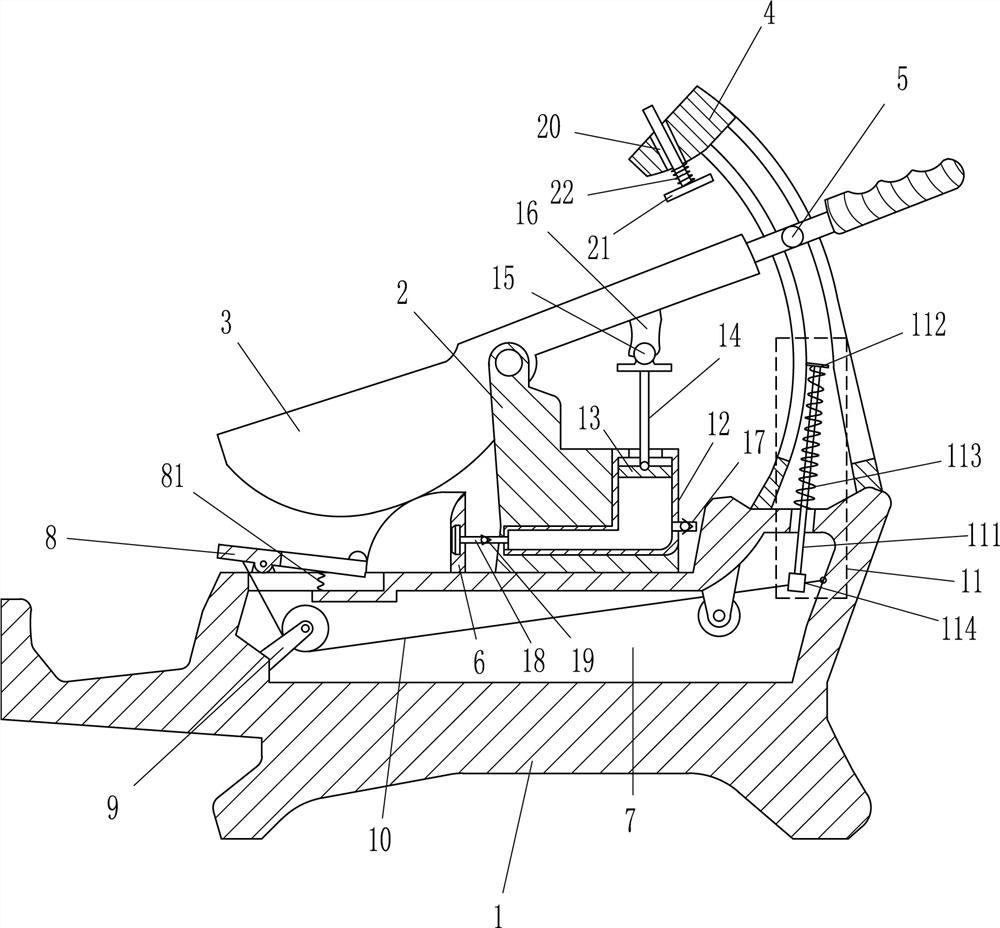

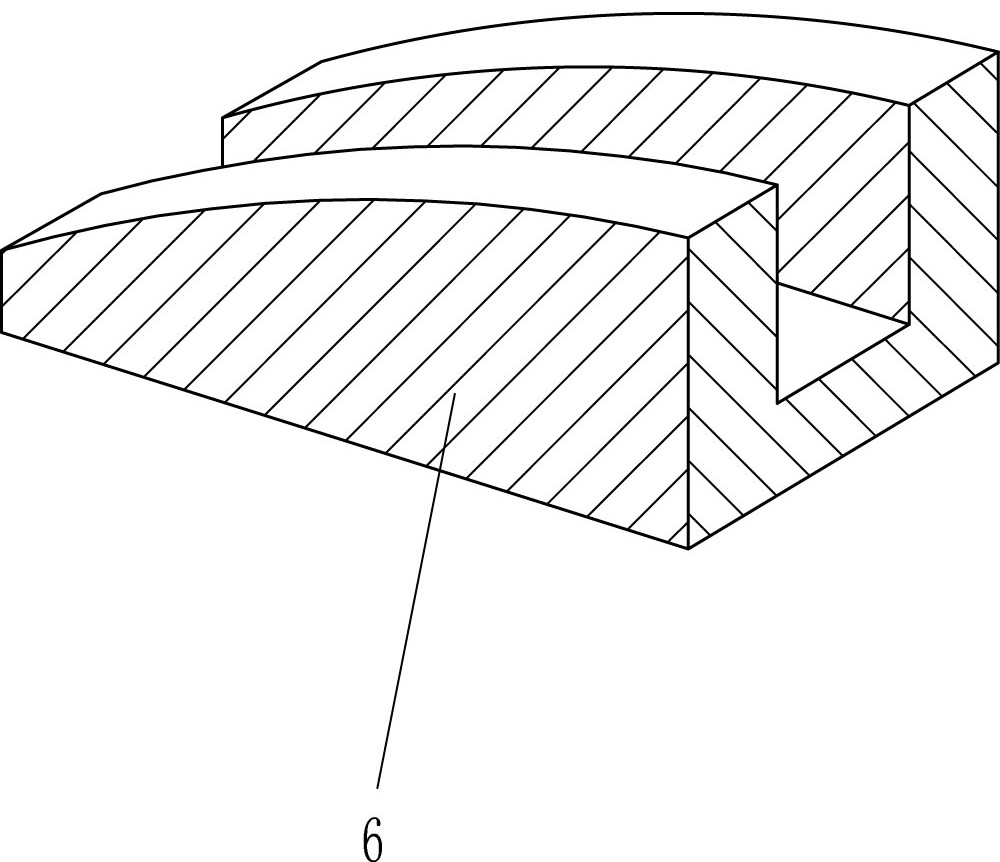

[0016] Such as Figure 1-3 As shown, a cuttage branch cutter includes a base 1, a bracket 2, a cutter 3, an arc guide rail 4, a sliding shaft 5, an N-shaped block 6, a swing plate 8, a first elastic member 81, and a guide wheel 9 , pull rope 10 and extruding device 11, the center of the top of the base 1 is provided with a bracket 2 by means of welding, a cutter 3 is rotatably arranged on the bracket 2, a sliding shaft 5 is arranged at the handle of the cutter 3, and the top of the base 1 is on the right There is an arc-shaped guide rail 4 on the side, and the sliding shaft 5 is slidably connected to the arc-shaped guide rail 4. An N-shaped stopper 6 is arranged on the left side of the top of the base 1, and the N-shaped stopper 6 is matched with the gap between the blades. The base 1 has an inner cavity 7 , there is a square hole on the left side of the top of the base 1, and a swing plate 8 is rotated at the square hole. There is a first elastic member 81, the first elastic...

Embodiment 2

[0020] Such as Figure 1-3 Shown, a kind of cuttage branch cutter also includes L-shaped cylinder body 12, piston 13, push rod 14, card ball 15, ferrule 16, air inlet pipe 17, air outlet pipe 18 and one-way valve 19, support 2. There is an L-shaped cylinder 12 embedded in it. A piston 13 is movable in the L-shaped cylinder 12. A push rod 14 is rotated on the piston 13. The other end of the push rod 14 is provided with a ball 15 and a cutter 3. A ferrule 16 is provided at the handle of the knife, and the ferrule 16 cooperates with the clamping ball 15. An air inlet pipe 17 is arranged on the side of the L-shaped cylinder body 12 close to the arc guide rail 4, and the side of the L-shaped cylinder body 12 is close to the N-shaped block 6. An air outlet pipe 18 is provided, and a check valve 19 is arranged between the air outlet pipe 18 and the air inlet pipe 17 .

[0021] The staff presses the handle of the cutter 3 downwards, and the handle of the cutter 3 moves downward throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com