A device for vibrating powder cleaning in the inner cavity and finishing the inner surface of laser selective melting and forming products

An inner surface and product technology, applied in the field of post-processing of additive manufacturing, to achieve the effect of efficient and rapid cleaning and improvement of the surface quality of the inner cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

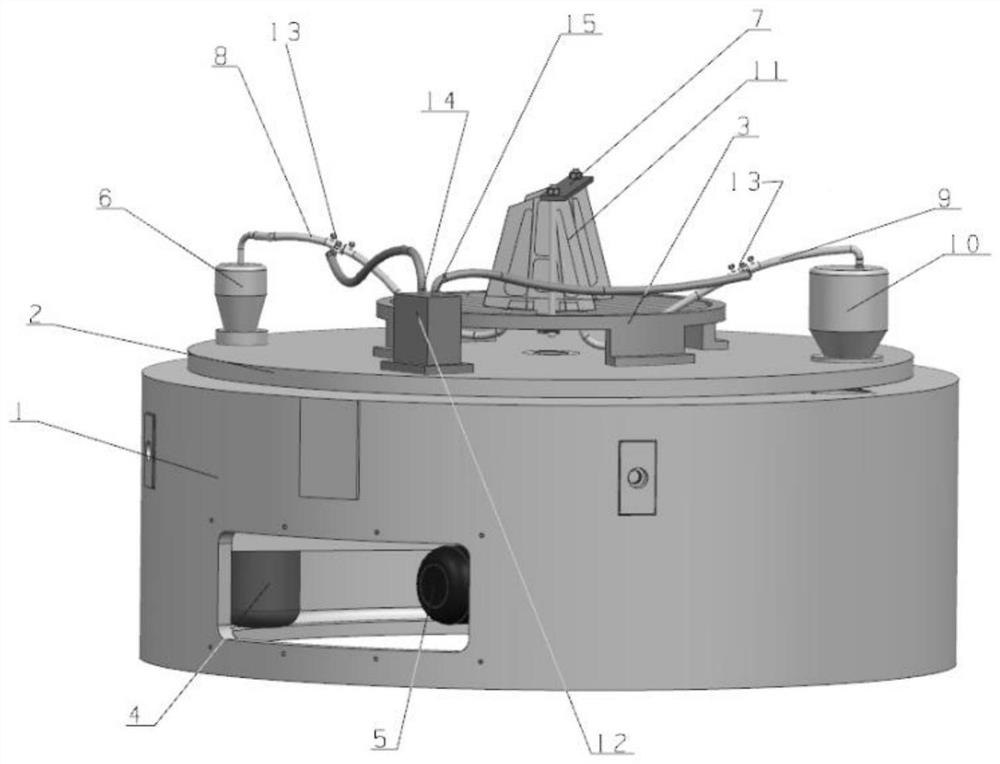

[0020] This embodiment proposes a device for vibrating powder cleaning in the inner cavity and finishing the inner surface of laser selective melting and forming products. Its structure is as follows figure 1 shown. The equipment includes a working table 1, a vibrating rotary table 2, a vibrating motor 4, a rotating motor 5, a compressed air generator 6, a workpiece support frame 3, a pressing tool 7, a powder collection cylinder 10, an electrochemical polishing workstation 12, and an air intake pipe 8 , Gas outlet pipe 9, anode pipeline 14, cathode pipeline 15 and three-way switch 13.

[0021] Among them, the workbench 1 is the main frame of the vibrating powder cleaning and inner surface finishing equipment. A rotati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap