Manufacturing method of motor rotor and motor rotor

A technology of a motor rotor and a manufacturing method, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as poor production efficiency, and achieve the effect of improving low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

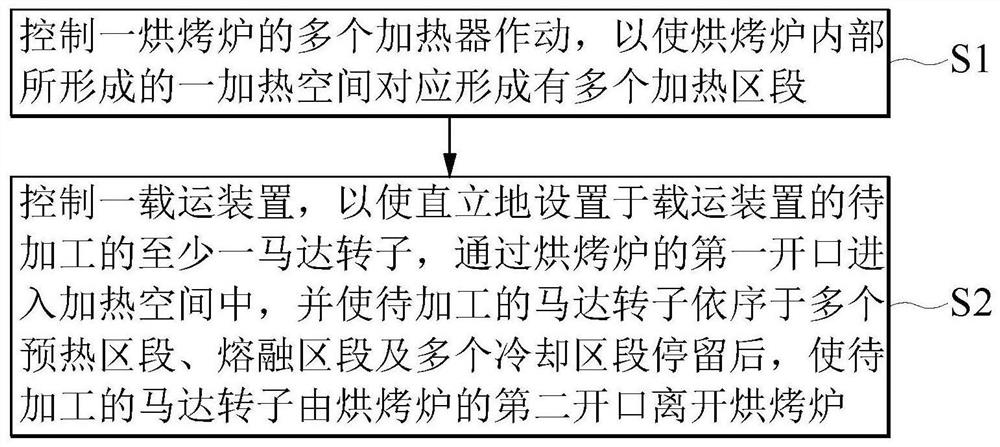

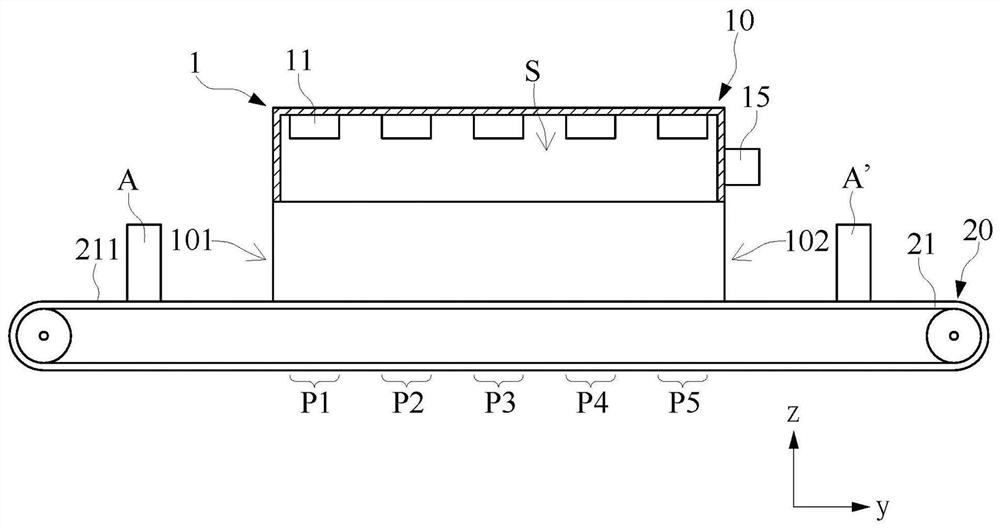

[0028]Please refer tofigure 1 andfigure 2 ,figure 1 A flow schematic of the method of manufacturing the motor rotor of the present invention,figure 2 A baking furnace according to the method of manufacturing the motor rotor of the present invention. Such asfigure 1 As shown, the method of manufacturing the motor rotor of the present invention contains the following steps:

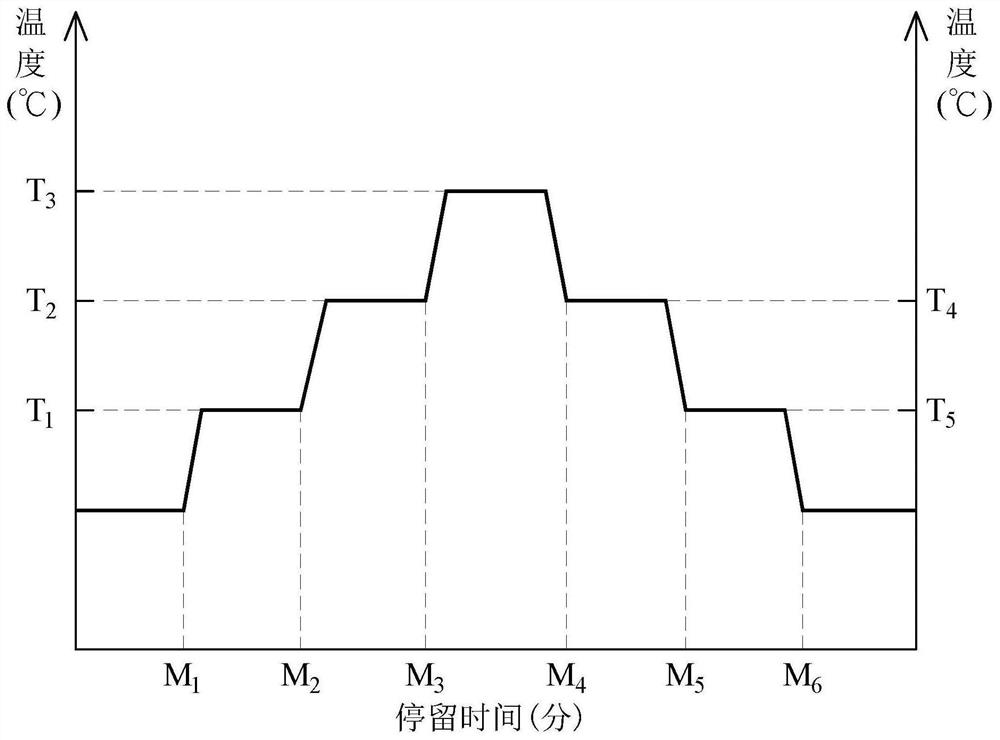

[0029]One preparing step S1: controls the plurality of heaters of the baking furnace to operate to enable a plurality of heating segments in which a heating space formed inside the baking furnace is formed.

[0030]A heating step S2: Controls a carrier device to enable at least one motor rotor to be machined in the carrier to enter the heating space through the first opening of the baking furnace, and the motor rotor to be processed in more After the preheating section, the molten segment and the plurality of cooling zones are left, the motor rotor to be processed is separated from the second opening of the baking furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com