Production equipment and production process of a cemented carbide blade

A technology for cemented carbide blades and production equipment, which is applied in metal material coating technology, cleaning methods using tools, vacuum evaporation coating, etc., can solve the problems of low production efficiency of blades, achieve low production efficiency, reduce Time and energy consumption, the effect of shortening downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

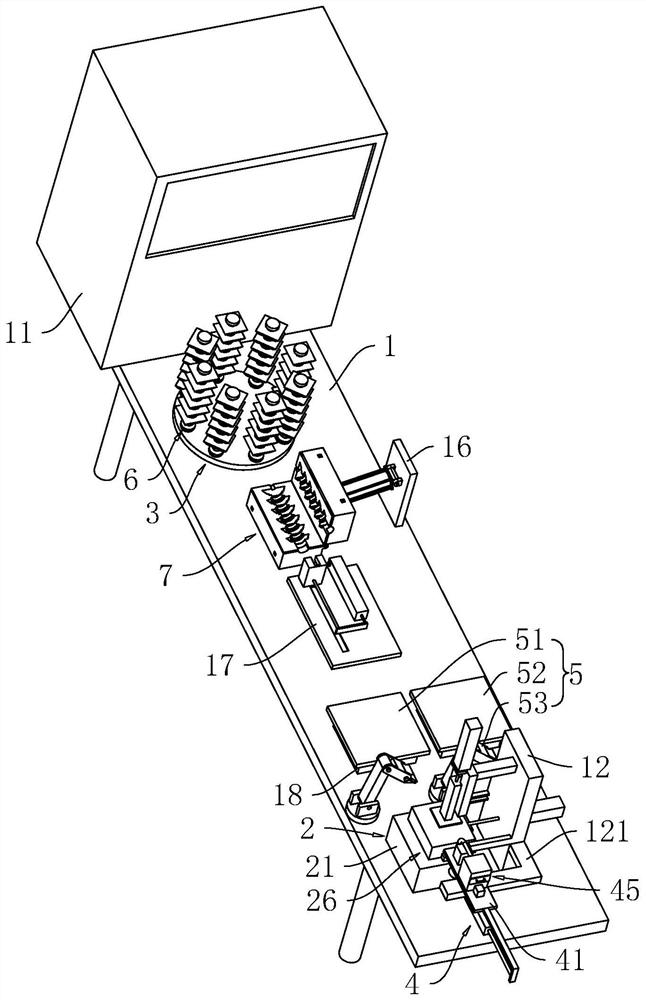

[0053] Below in conjunction with accompanying drawing 1-8, the present application is described in further detail.

[0054] The embodiment of the present application discloses a production equipment of cemented carbide inserts.

[0055] In this embodiment, the weight detector 51 is a gravity sensor, and the model of the gravity sensor is JLBU-1.

[0056] refer to figure 1 , The production equipment of cemented carbide blades includes a frame 1, on which a pressing mechanism 2 for pressing blades, a blade carrying mechanism 3, and a vapor deposition furnace 11 are sequentially arranged on the frame 1 and along the length direction of the frame 1.

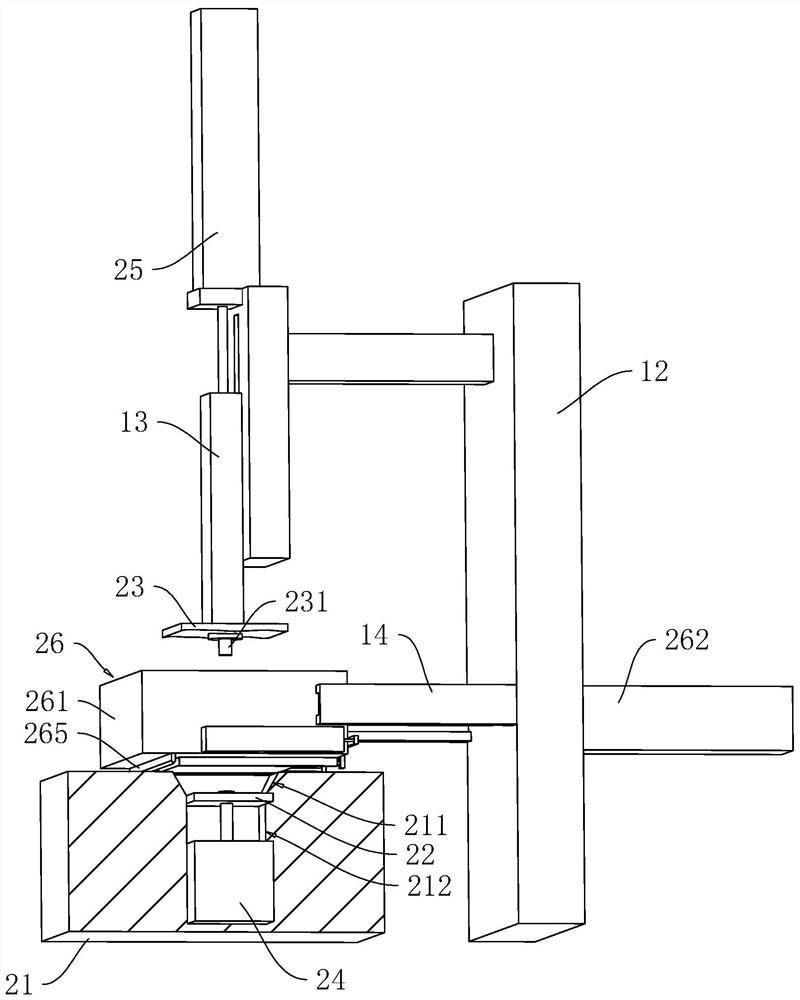

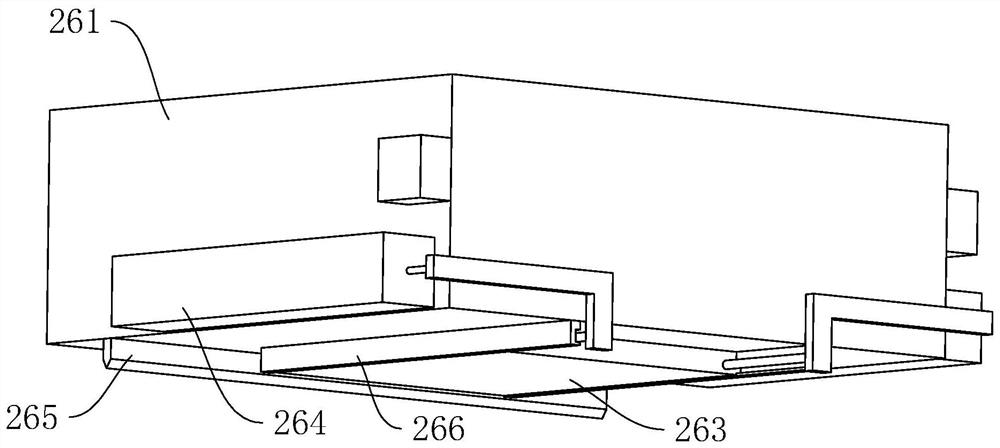

[0057] refer to figure 1 and figure 2 , the middle position of the blade is provided with a mounting hole, and the blade is fixedly mounted on the cutter bar by setting screws on the mounting hole; the pressing mechanism 2 includes a mold plate 21, a lower template 22, an upper template 23, a first lifting cylinder 24, a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com