Full-guarded five-axis machining center

A five-axis machining center and full protection technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of occupying operating space, affecting the safety of operators, and large safety doors, so as to improve processing accuracy, The effect of small changes in straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

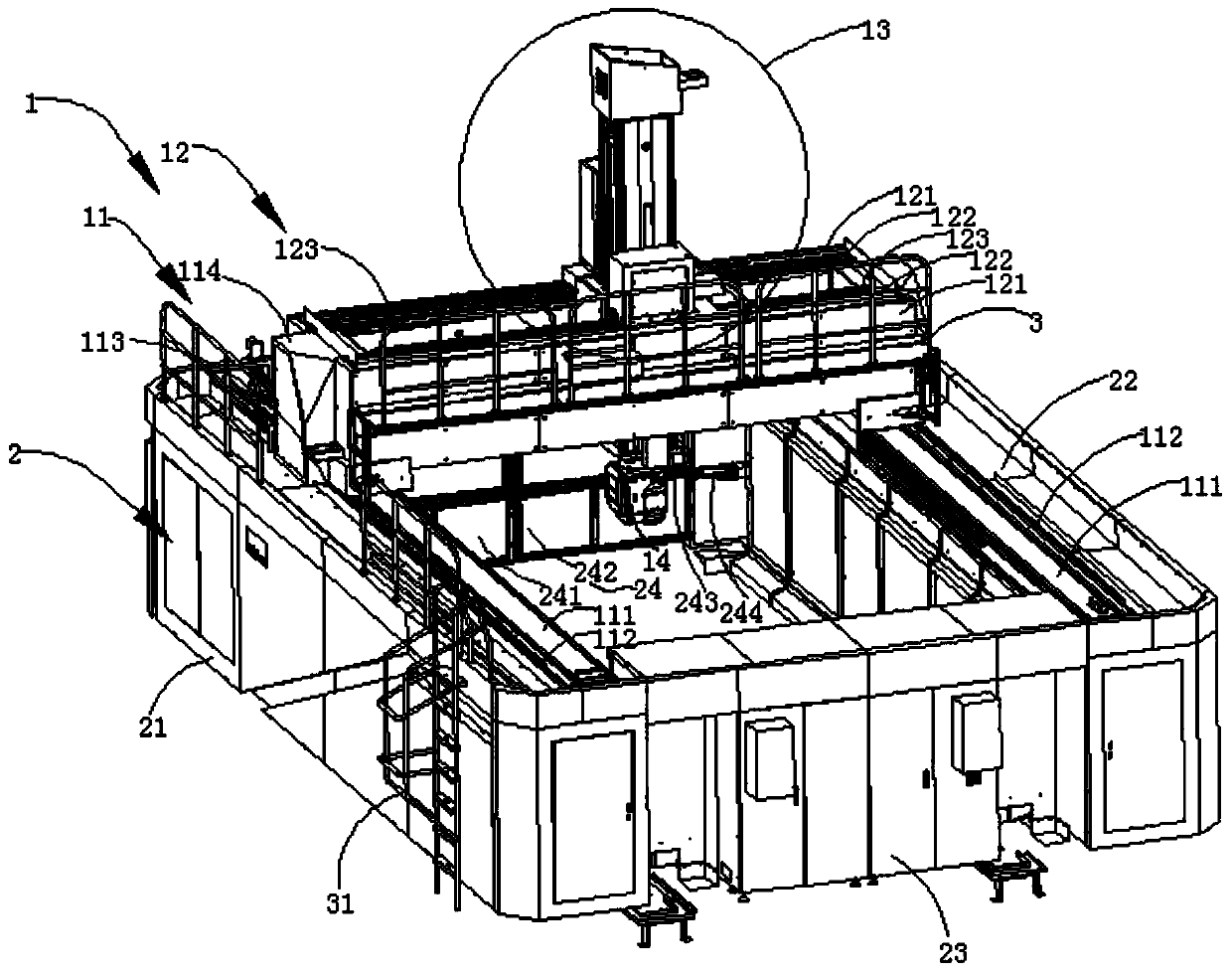

[0025] A fully protected five-axis machining center, such as figure 1 As shown, it includes a five-axis machining center 1, a safety gate 2 and a safety guardrail 3, wherein the safety gate 1 is installed under the five-axis machining center 1 as a base frame, and the safety guardrail 3 is installed on the upper edge of the safety gate 1; The safety gear door 1 comprises a left safety gear door 21, a right safety gear door 22, and a front safety gear door 23 and a rear safety gear door 24 respectively hinged with the left safety gear door 21 and the right safety gear door 22; and the left safety gear door The outer periphery of 21 is equipped with the climbing ladder 31 that is convenient for the operator to step on.

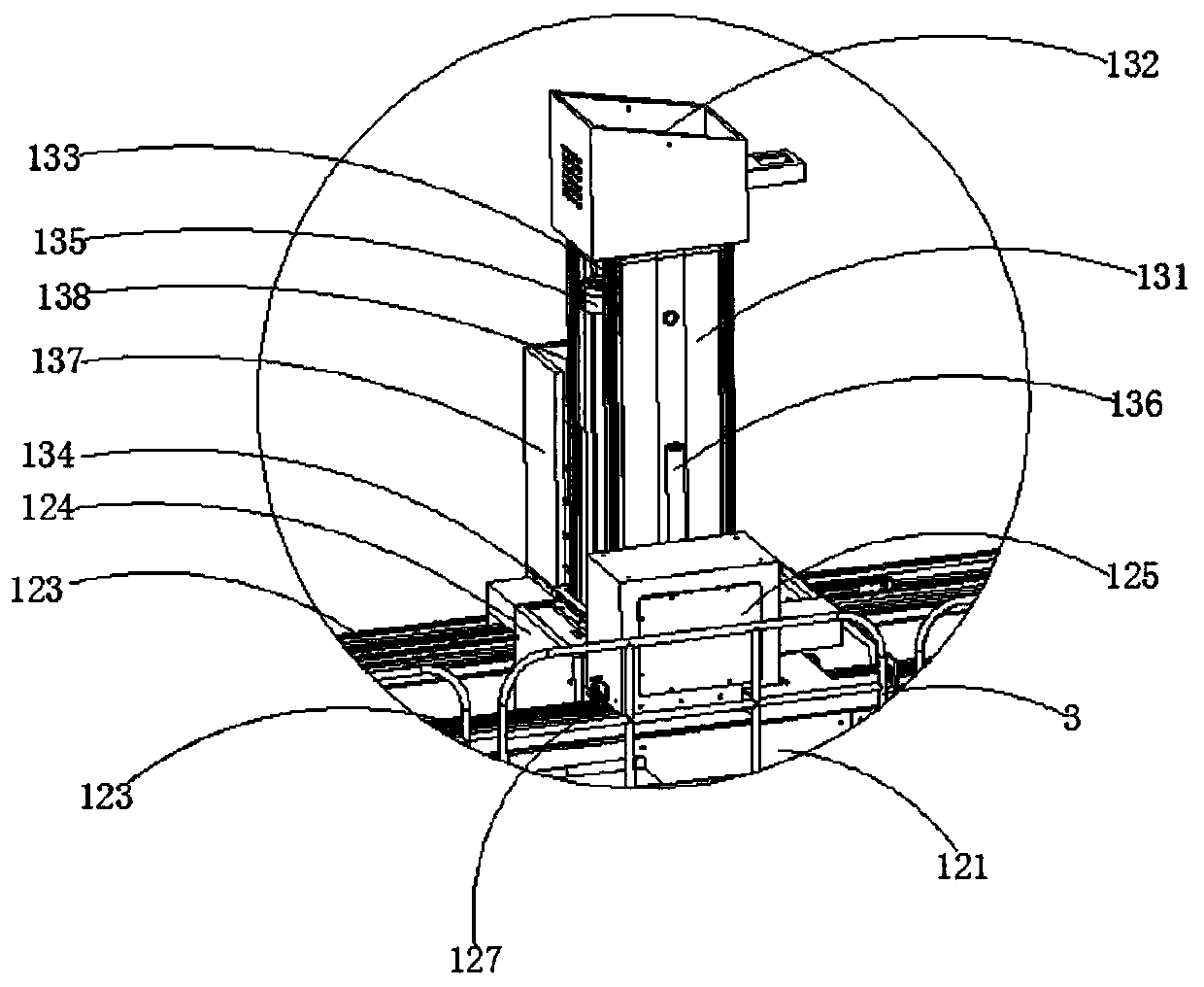

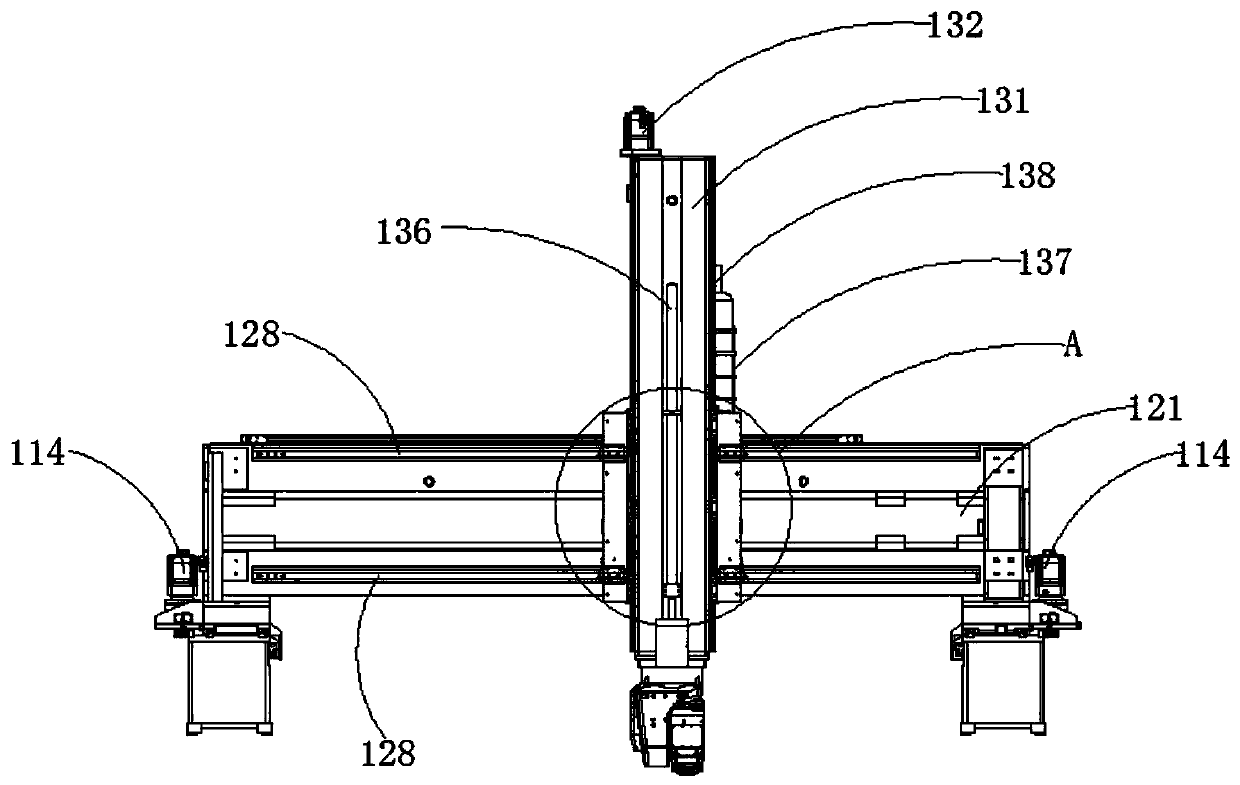

[0026] Such as figure 1 As shown, the five-axis center 1 includes a longitudinal displacement mechanism 11 installed above the left safety gear door 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com