A right-angle guide rail and cabinet

A technology for right-angle guide rails and cabinets, applied in the field of guide rails, can solve the problems of difficulty in guaranteeing the machining accuracy of sheet metal cabinets, limited adjustment clearance of L-shaped right-angle guide rails, and difficulty in adjusting the installation form, and achieves improved adjustment efficiency, strong applicability, and reduced adjustment. The effect of speed and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

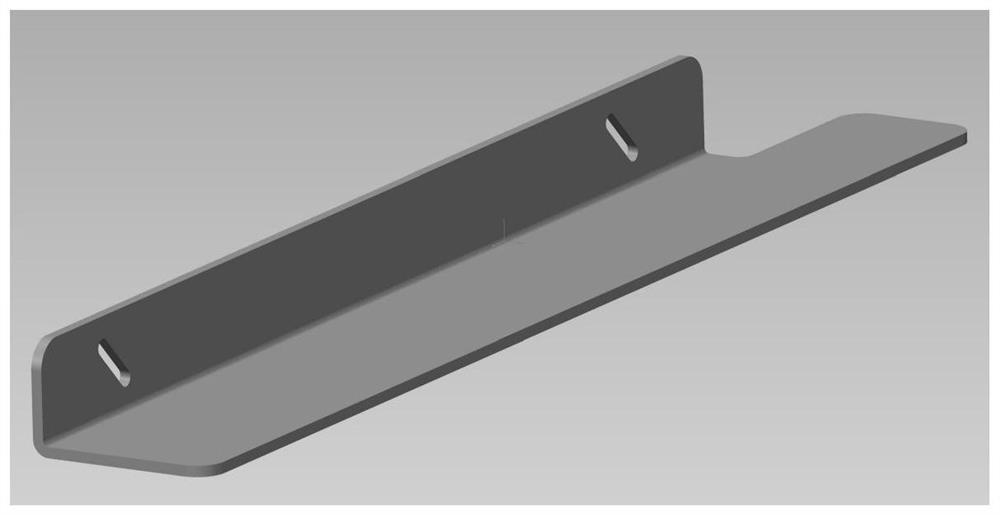

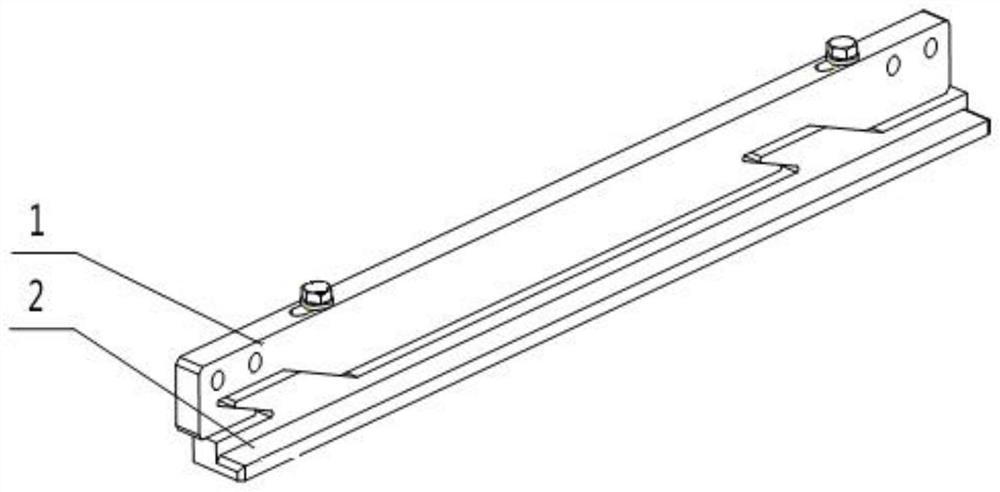

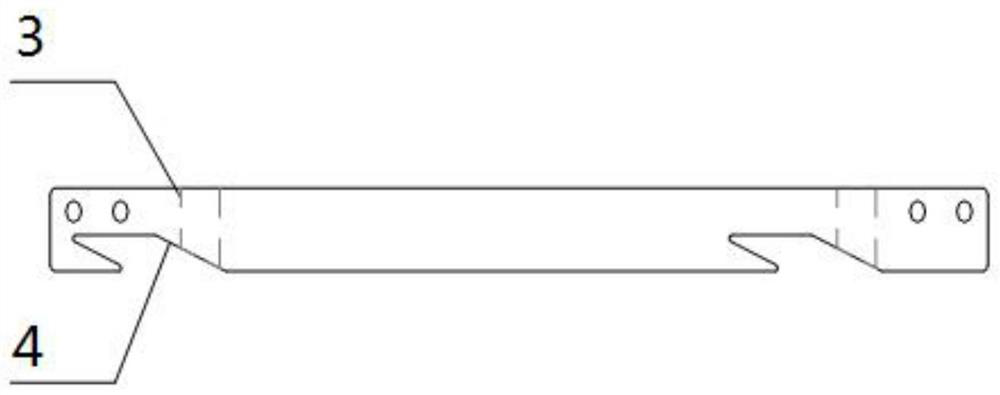

[0033] This embodiment discloses a right-angle guide rail, such as Figure 2-4 As shown, the right-angle guide rail includes a male rail 1 and a female rail 2; the female rail 2 includes a base 21 and a slide rail 22, the base 21 is a cuboid, and the slide rail 22 is arranged on the side of the base 21, along the length direction of the base 21 Extension; the upper surface of the base 21 is provided with a connecting portion 23, and the connecting portion 23 is a parallelepiped whose longitudinal section is a parallelogram; the male track 1 is a cuboid, and the male track 1 is provided with a groove 4 cooperating with the connecting portion 23; Track 1 and parent track 2 are movably connected.

[0034] Compared with the prior art, the female track provided in this embodiment is provided with a connecting part 23 whose longitudinal section is a parallelogram, and a groove matching the connecting part 23 is provided on the male track, and the male track 1 and the female track 2 ...

Embodiment 2

[0053] This embodiment discloses a right-angle guide rail, such as Figure 2-4 As shown, the right-angle guide rail includes a male rail 1 and a female rail 2; the female rail 2 includes a base 21 and a slide rail 22, the base 21 is a cuboid, and the slide rail 22 is arranged on the side of the base 21, along the length direction of the base 21 Extension; the upper surface of the base 21 is provided with a connecting portion 23, and the connecting portion 23 is a parallelepiped whose longitudinal section is a parallelogram; the male track 1 is a cuboid, and the male track 1 is provided with a groove 4 cooperating with the connecting portion 23; The track 1 and the parent track 2 are movably connected, specifically, the base 21 of the parent track 2 has a length of 400 mm.

[0054] Specifically, a waist-shaped through hole 3 is provided on the upper surface of the male rail 1, and a threaded hole is provided on the connecting portion 23, and the bolt passes through the waist-sh...

Embodiment 3

[0063] This embodiment discloses a cabinet, such as Figure 5 As shown, including the cabinet main body 6 and the right-angle guide rail 5 provided in Embodiment 1, the cabinet main body is provided with columns for installing the right-angle guide rails, and the right-angle guide rails are installed and fixed on the columns on both sides of the cabinet main body through the mounting holes on the male rail. Install and use in pairs.

[0064] During the implementation, the subrack is placed on the right-angle guide rail. Compared with the traditional technology, when adjusting the position of the subrack, it is not necessary to remove the subrack above the guide rail first, and it is not necessary to roughly adjust the height of the guide rail by loosening the bolts of the guide rail and the cabinet. , rely on the experience of the operator to evaluate whether the height of the guide rail is appropriate, and then reinsert the subrack into the cabinet to confirm whether the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com