A remote real-time monitoring system for welding robot system

A welding robot and real-time monitoring technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of single-machine control, monitoring efficiency and automation, affecting the efficiency of production and processing, etc. , to reduce losses, improve human-computer interaction, and facilitate operation and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

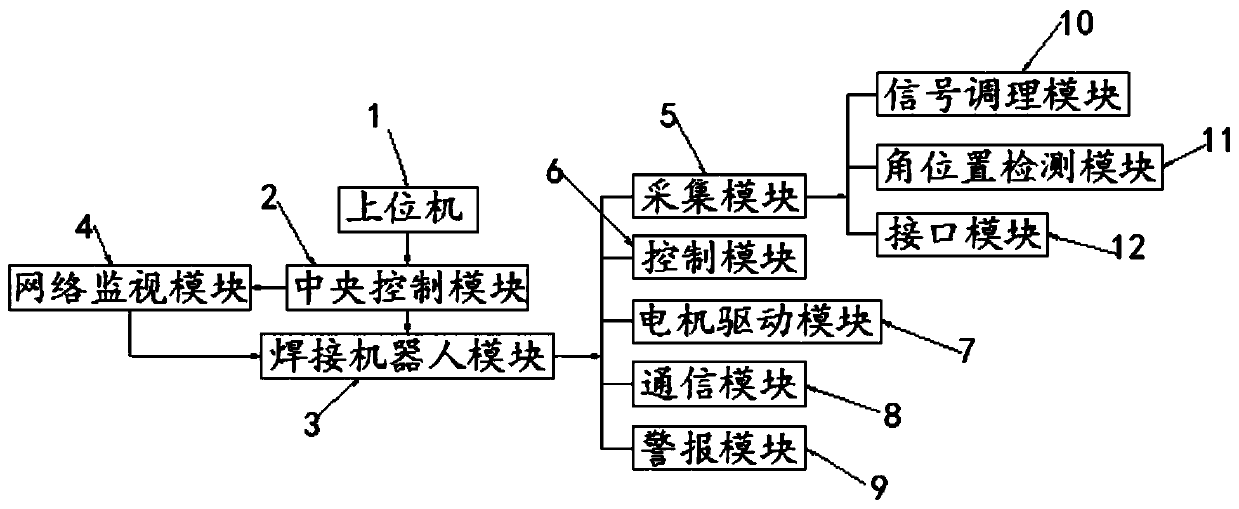

Embodiment 1

[0029] Embodiment one, such as Figures 1 to 6 As shown, a remote real-time monitoring system for a welding robot system according to an embodiment of the present invention includes a host computer 1, a central control module 2, a welding robot module 3 and a network monitoring module 4, and the welding robot module 3 can directly pass through its A field bus card with a PCI slot communicates with peripheral devices, transmits signals and processes I / O. For each robot, a two-level field bus system is used, and the output terminal of the upper computer 1 is connected to the central control module 2. The input end of the central control module 2 is connected with the input end of the welding robot module 3 and the network monitoring module 4 respectively, and the communication module 8 is used to communicate between the robot and the robot. The central control module 2 communicates with all The communication between the robots is all realized by industrial Ethernet, and each rob...

Embodiment 2

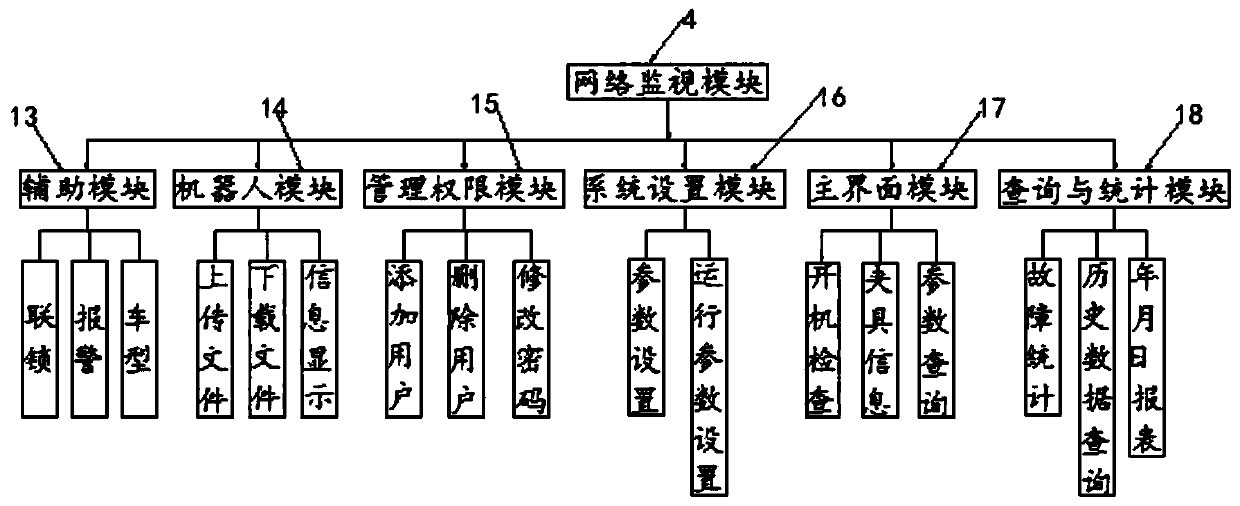

[0030] Embodiment two, such as figure 2 As shown, the output terminals of the network monitoring module 4 are respectively connected with the auxiliary module 13 , the robot module 14 , the management authority module 15 , the system setting module 16 , the main interface module 17 and the query and statistics module 18 .

Embodiment 3

[0031] Embodiment three, such as figure 2 As shown, the auxiliary module 13 includes interlocking, alarm and vehicle models, the robot module 14 includes uploading files, downloading files and information display, the management authority module 15 includes adding users, deleting users and modifying passwords, the system The setting module 16 includes parameter setting and operating parameter setting, the main interface module 17 includes power-on inspection, fixture information and parameter query, and the query and statistics module 18 includes fault statistics, historical data query and year, month and day reports.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com