Bonding mechanism and bonding method of inner bag and outer bag of double-layer bag

A double-layer bag, outer bag technology, applied in bag making operations, container manufacturing machinery, paper/cardboard containers, etc., can solve the problems of increased time required, pollution of inner bag body, wear of adhesive joints, etc., and achieve the effect of adjustment Better, prolong service life, reduce the effect of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

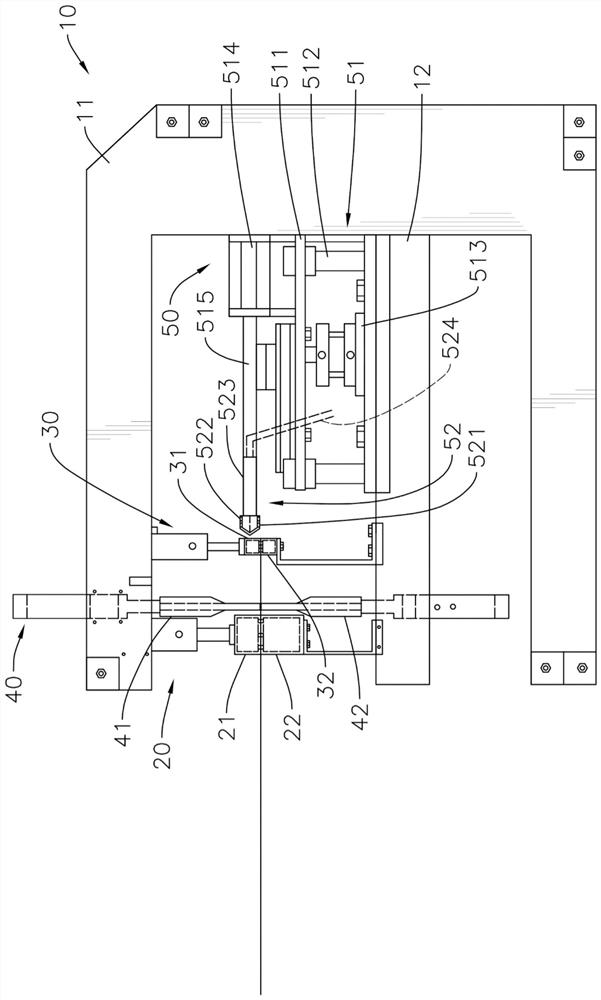

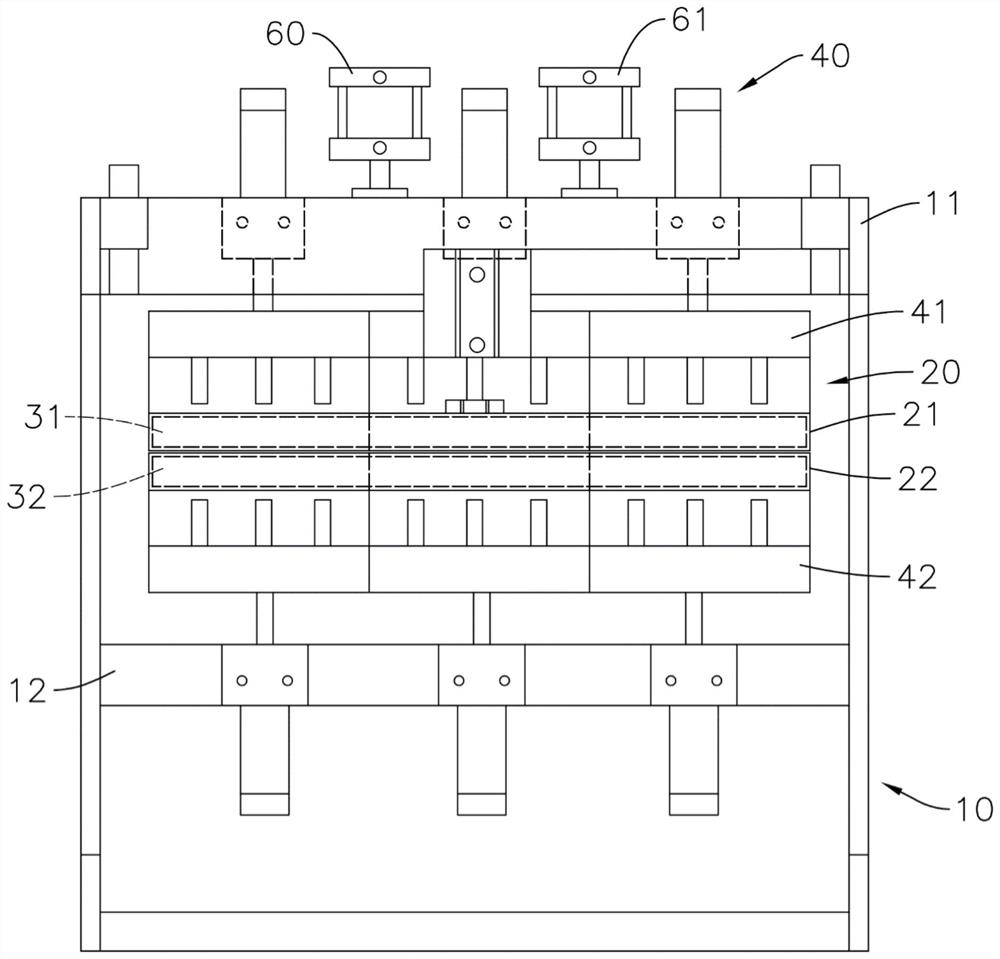

[0056] Please refer to figure 1 As shown, the bonding mechanism of the inner bag and the outer bag of the double-layer bag of the present invention includes a base 10 , a first suction cup 20 , a second suction cup 30 , an engaging device 40 and a positioning device 50 .

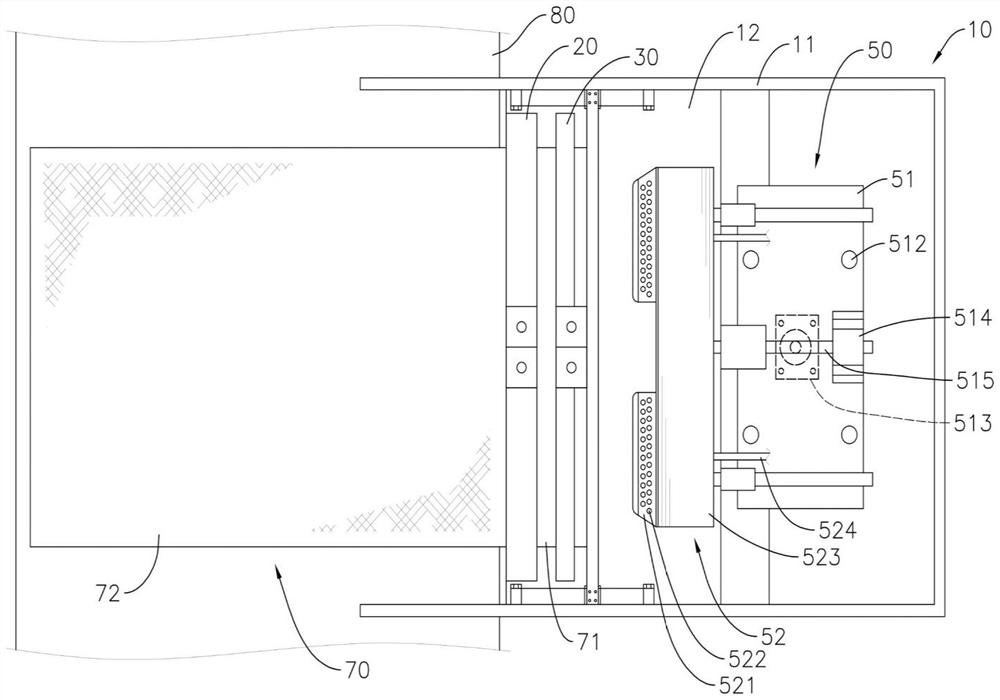

[0057] Please refer to image 3 and Figure 9 As shown, the double-layer bag 70 referred to in the present invention has an inner bag 71 and an outer bag 72, and one end of the inner bag 71 and the outer bag 72 has an opening respectively, and the other ends are all closed, and the inner bag 71 is located in the outer bag. 72, and one end of the opening of the inner bag 71 protrudes from the opening of the outer bag 72 to form a protrusion 711. In this embodiment, the outer bag 72 is a woven bag, and the inner bag 71 is a bag body of PE (Polyethylene) film .

[0058] Please refer to figure 1 As shown, the base 10 has an upper seat 11 and a lower seat 12; in the present embodiment, the base 10 is a simila...

Embodiment 2

[0082] see Figure 11 and 12 As shown, the difference between this embodiment and Embodiment 1 is that a flattening device 43 is movable on the upper joint 41, and the flattening device 43 includes a pressing bag 431 and a reset device 432, and the pressing bag 431 is arranged on the side of the upper joint 41 outer periphery, and is flexibly connected with the upper joint 41 through the reset device 432, the bottom of the pressure bag 431 is a structure formed by points and / or lines and / or surfaces, the bottom structure of the pressure bag 431 is horizontal and coplanar, and the reset device 432 is elastic Reset device, and the elastic expansion and contraction direction is consistent with the moving direction of the upper joint 41, the pressure bag 431 can move in the expansion and contraction direction of the reset device 432, the adhesive end of the upper joint 41 is located within the movement range of the bottom end of the pressure bag 431, the upper joint When 41 moves...

Embodiment 3

[0094] Such as Figure 14As shown, the structure of the device is further optimized. Compared with Embodiment 2 in this embodiment, the third suction cup 52 further includes a pressing plate 523 and a bag supporting device 525. The pressing plate 523 is arranged horizontally. The number of bag supporting devices 525 is 2. 525 can perform telescopic movement, and the bag supporting device 525 includes a bag supporting slat 5251 and a cylinder 5252, the cylinder 5252 is installed in the hollow cavity provided by the pressing plate 523, and the end of the piston rod of the cylinder 5252 is fixedly connected to the bag supporting slat 5251, and the bag is supported. The slats 5251 are L-shaped slats arranged along the adjacent two sides of the press plate 523, and are respectively arranged on both sides of the press plate 523. The top and bottom sides of the bag support slat 5251 are horizontally coplanar with the top and bottom of the press plate 523, and the cylinder 5252 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com