Cosmetic bottle with high material taking precision

A high-precision, cosmetic bottle technology, applied in the field of cosmetic bottles, can solve the problems of increased consumption, waste, and uncontrollable amount of finger digging, and achieve the effect of high precision and convenient control of extrusion volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

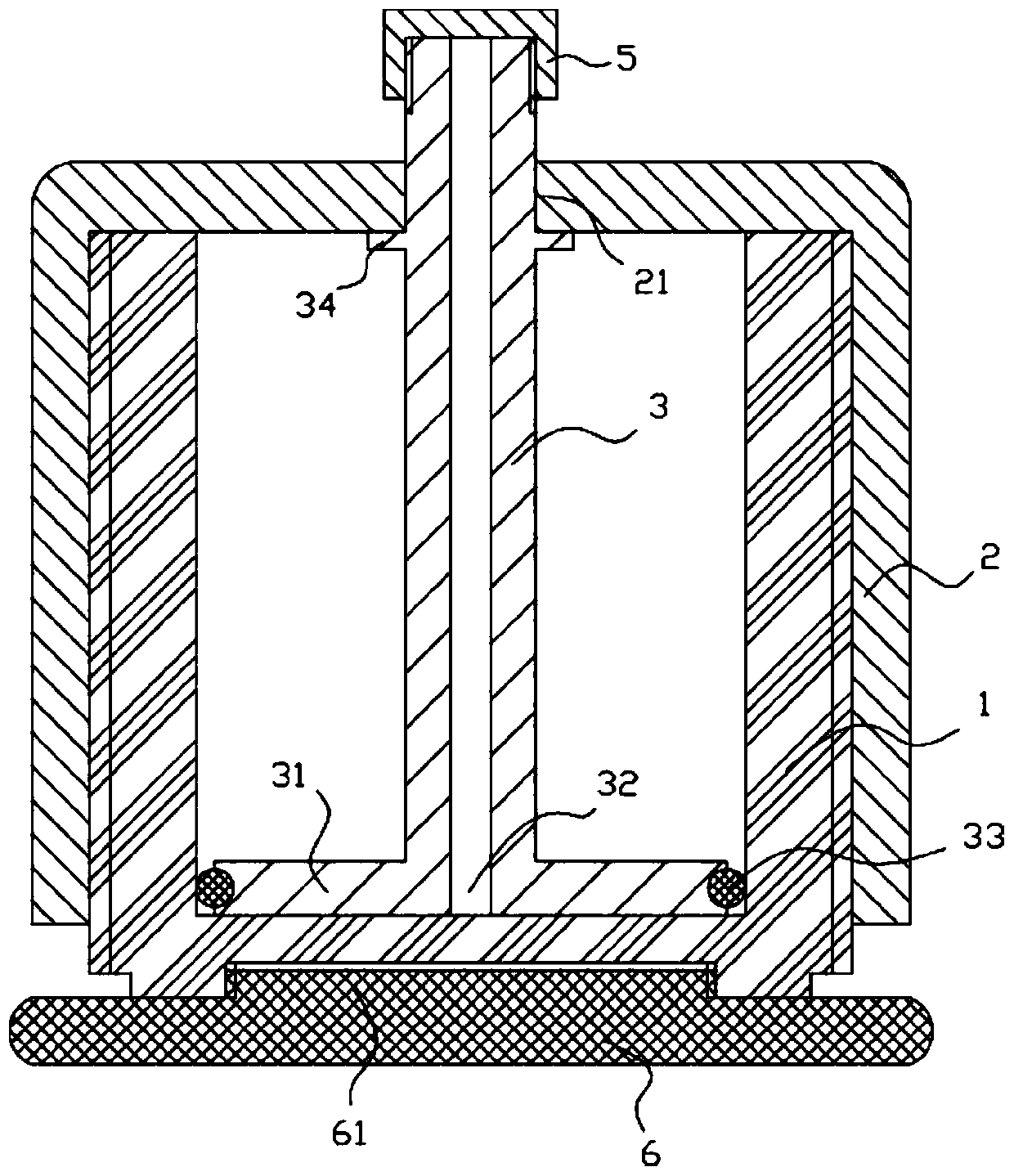

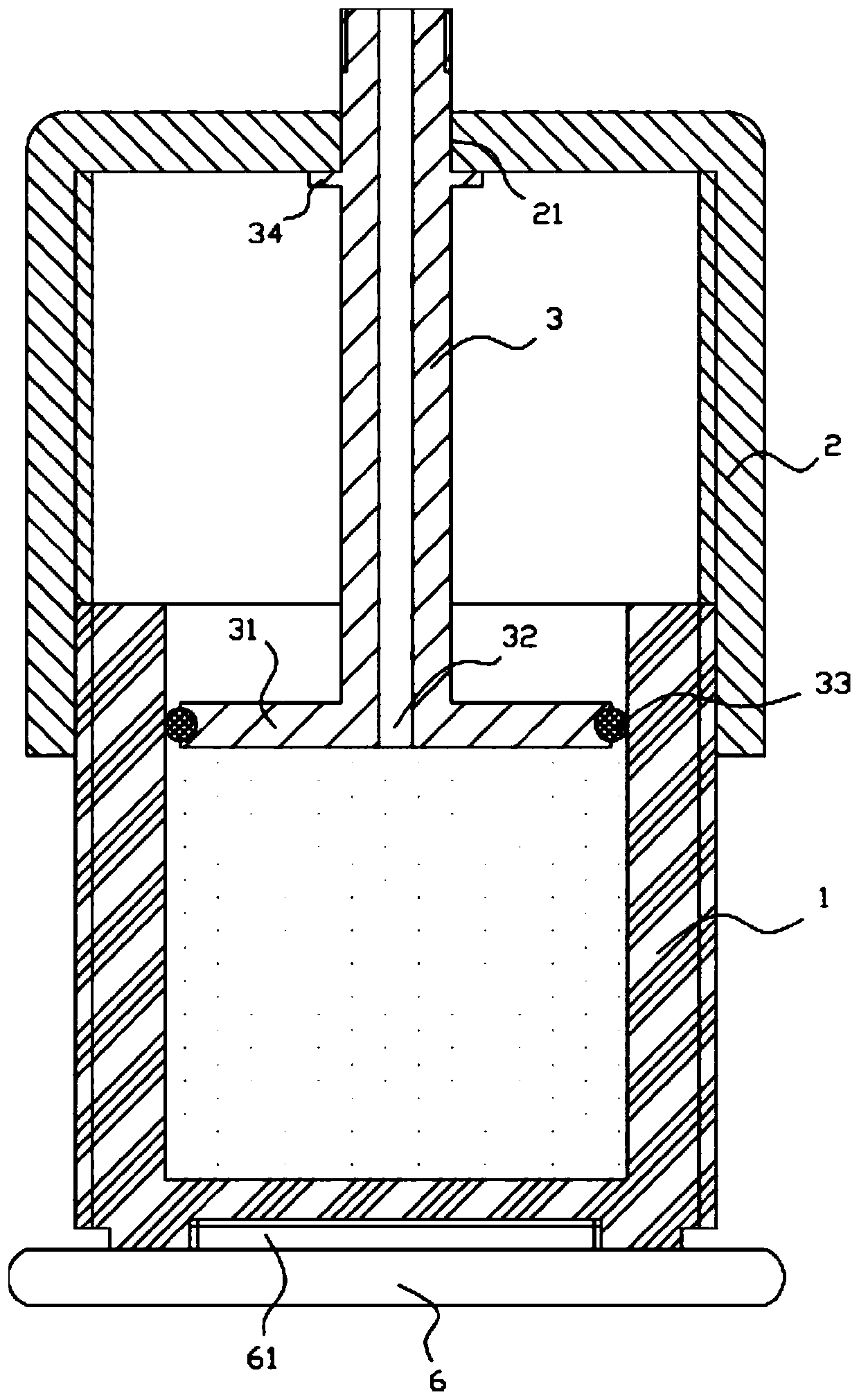

[0016] Example: see Figure 1 to Figure 2 As shown, a cosmetic bottle with high material extraction accuracy includes a bottle body 1, an external thread is formed on the outer wall of the bottle body 1, an internal thread is formed on the inner wall of the bottle sleeve 2, and the bottle body 1 is located in the bottle sleeve 2 , the internal thread and the external thread are screwed together, the middle part of the top plate of the bottle sleeve 2 has a central through hole 21, the liquid outlet pipe 3 is inserted into the central through hole 21, and the outer wall of the liquid outlet pipe 3 is close to the central through hole 21 The inner side wall of the liquid outlet pipe 3 is in the bottle body 1 and is formed with an extruding plate 31, the outer side wall of the extruding plate 31 is close to the inner side wall of the bottle body 1, and the extruding plate 31 is in the bottle body 1 , The through hole 32 formed in the middle of the extrusion plate 31 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com