Garbage can washing type garbage truck

A washing-type, garbage truck technology, applied in the direction of garbage collection, garbage storage, garbage cleaning, etc., can solve the problems of incomplete garbage dumping, non-cleaning, and environmental impact, and achieve easy popularization and application, simple structure, and prevention of residues Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

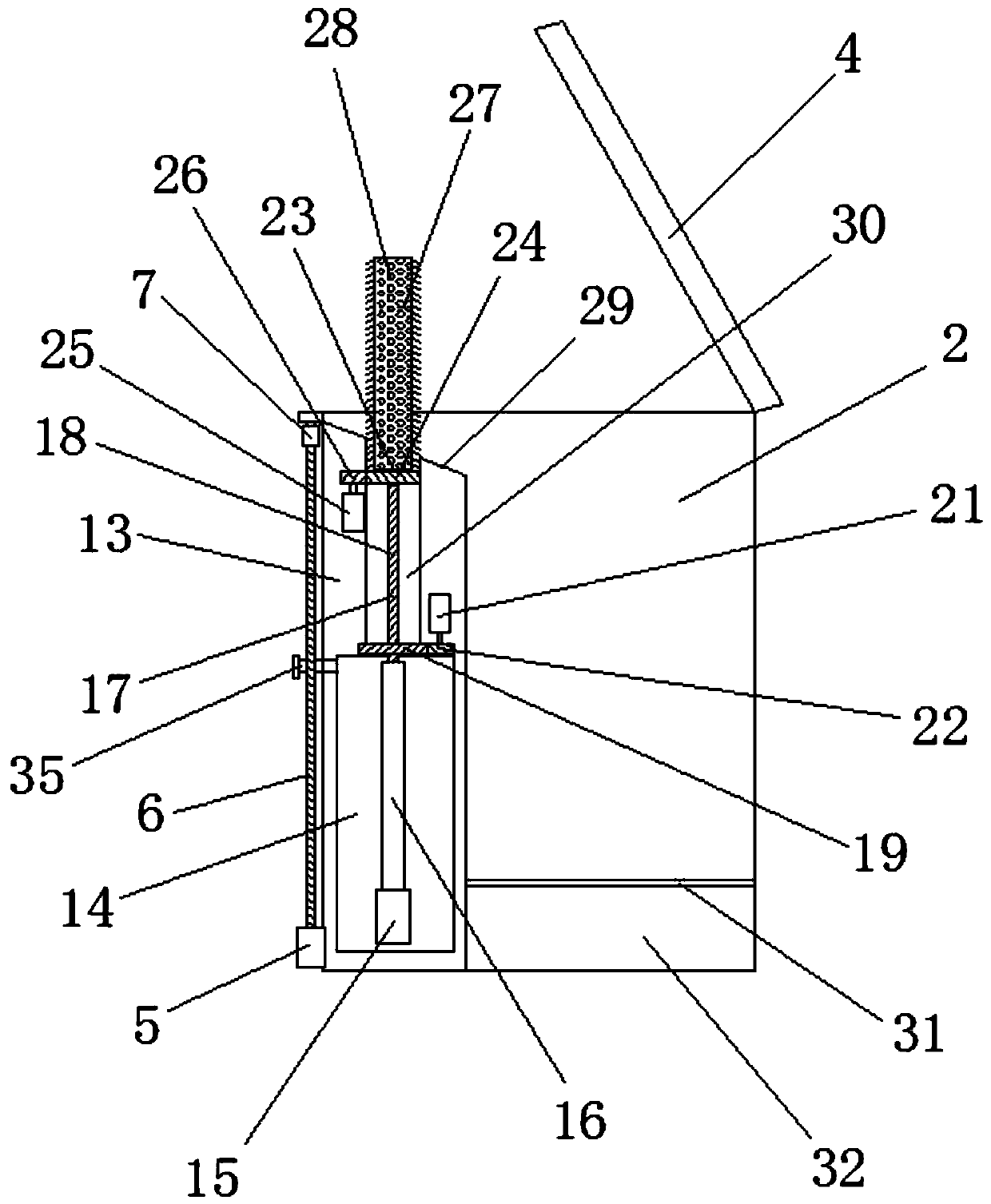

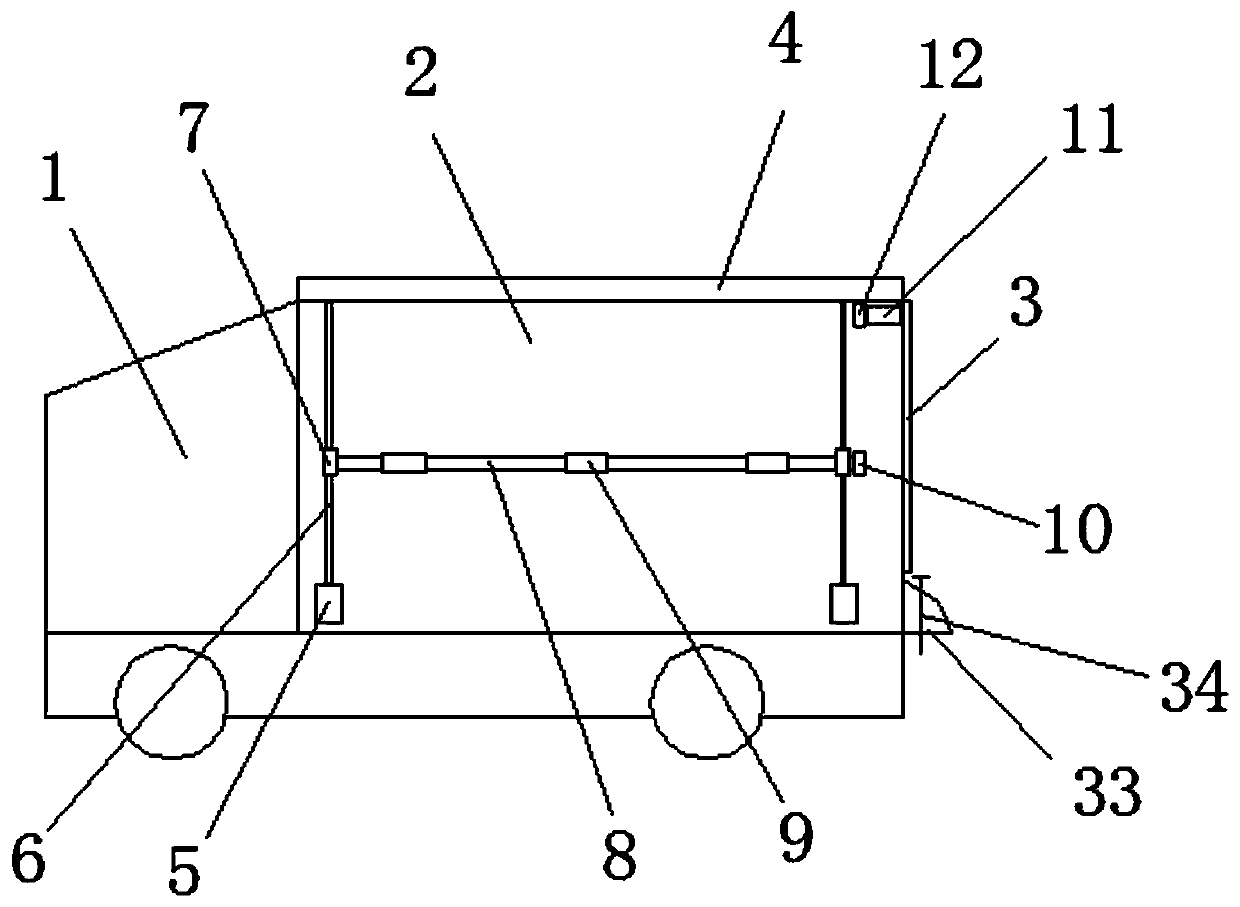

[0020] Embodiment 1: as Figure 1-4 As shown, a garbage can flushing type garbage truck includes: a car body 1, a compartment 2 is fixedly installed on the car body 1, a flip cover 4 is connected to the top of the compartment 2 in rotation, and the rear side of the compartment 2 There is a compartment door 3 in rotation connection;

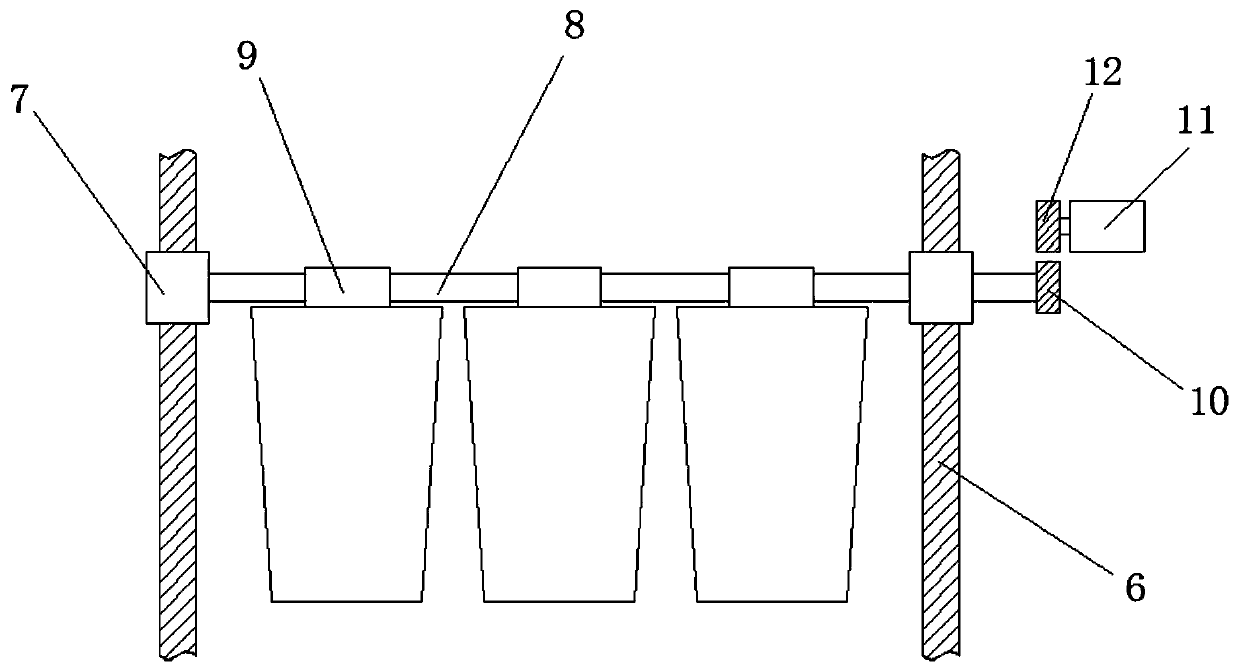

[0021] The bottom of both sides of the side wall of the compartment 2 is fixedly equipped with a first motor 5, and the top of the first motor 5 is fixedly connected with a screw rod 6, and the screw rods 6 of the two groups are all connected with a lifting frame 7 by threads. , a beam 8 is rotatably connected between the lifting frames 7 of the two groups, and the middle part of the beam 8 is fixedly connected with a plurality of fixed frames 9;

[0022] The right end of the beam 8 extends out of the lifting frame 7 and is fixedly connected with a first driven gear 10, and the upper right corner of the side wall of the compartment 2 is fixedly i...

Embodiment 2

[0026] Embodiment 2: as Figure 1-4 As shown, a trash can flushing type garbage truck includes: a car body 1, a compartment 2 is fixedly installed on the car body 1, a flip cover 4 is connected to the top of the compartment 2 in rotation, and the rear side of the compartment 2 There is a compartment door 3 in rotation connection;

[0027] The bottom of both sides of the side wall of the compartment 2 is fixedly equipped with a first motor 5, the top of the first motor 5 is fixedly connected with a screw 6, and the screw rods 6 of the two groups are all connected with a lifting frame 7 by threads. , a beam 8 is rotatably connected between the lifting frames 7 of the two groups, and the middle part of the beam 8 is fixedly connected with a plurality of fixed frames 9;

[0028] The right end of the beam 8 extends out of the lifting frame 7 and is fixedly connected with the first driven gear 10, and the upper right corner of the side wall of the compartment 2 is fixedly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com