Glass fiber cloth roll rail transport vehicle

A rail transport vehicle, glass fiber technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of increased transportation costs, labor, safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

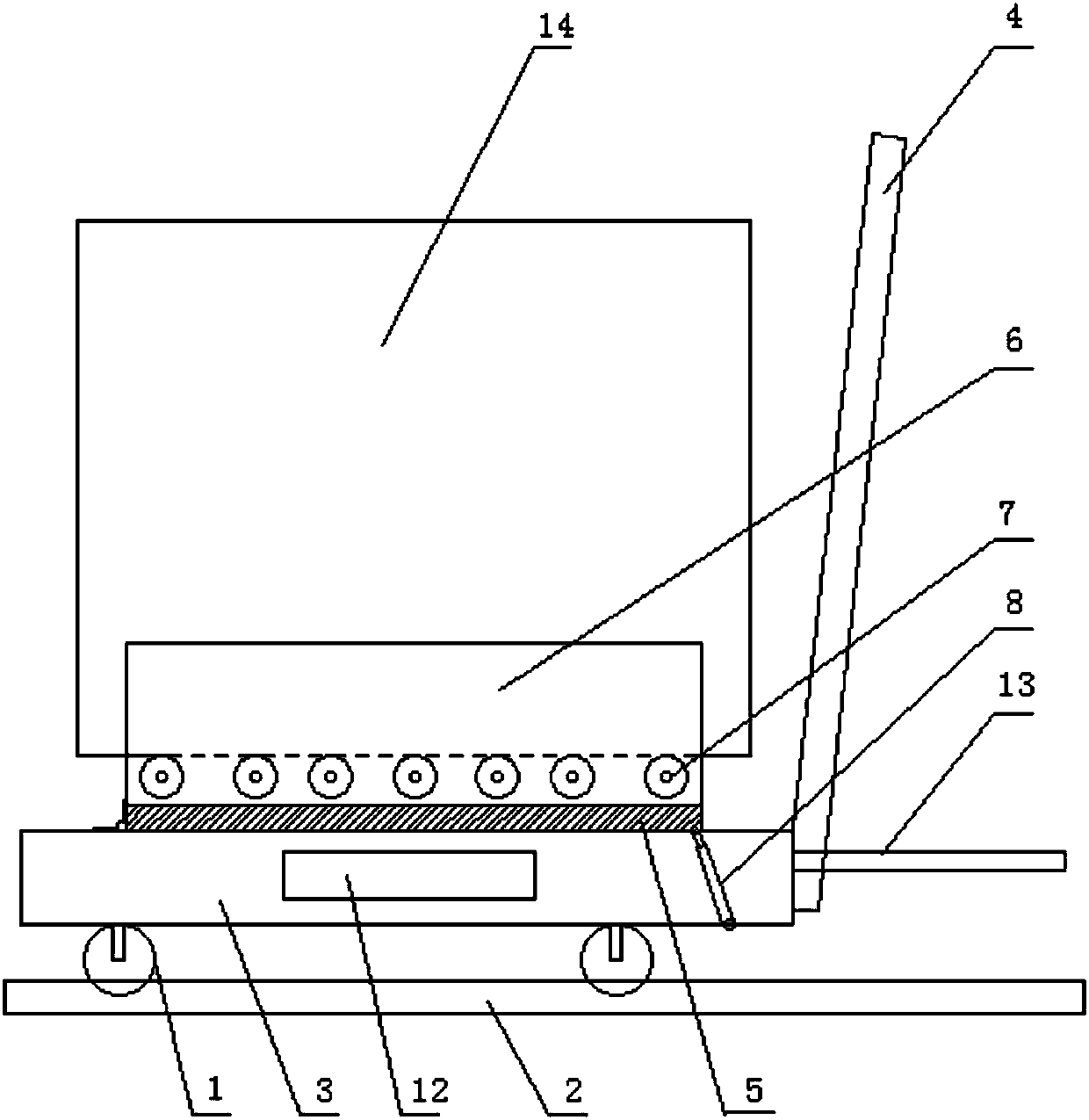

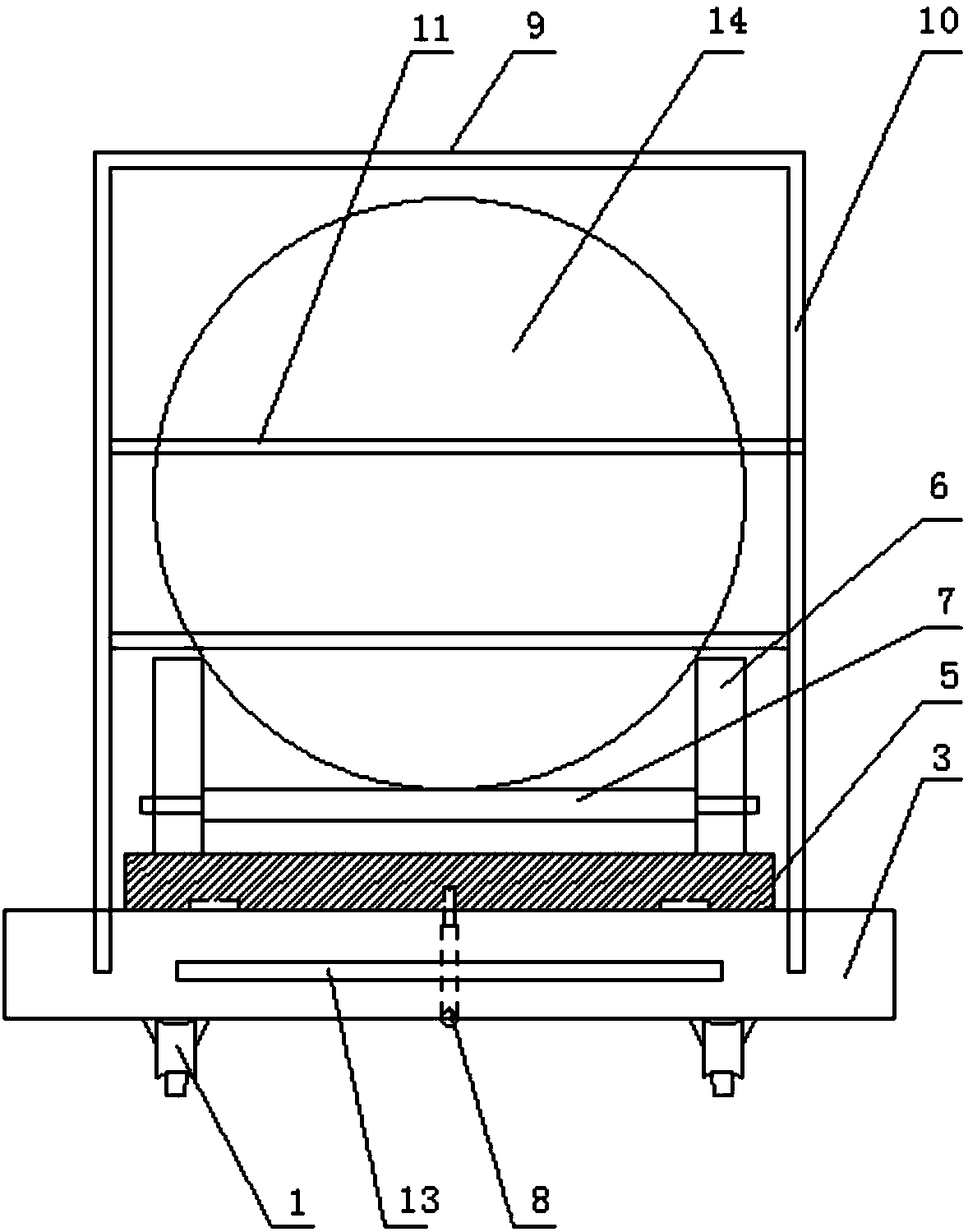

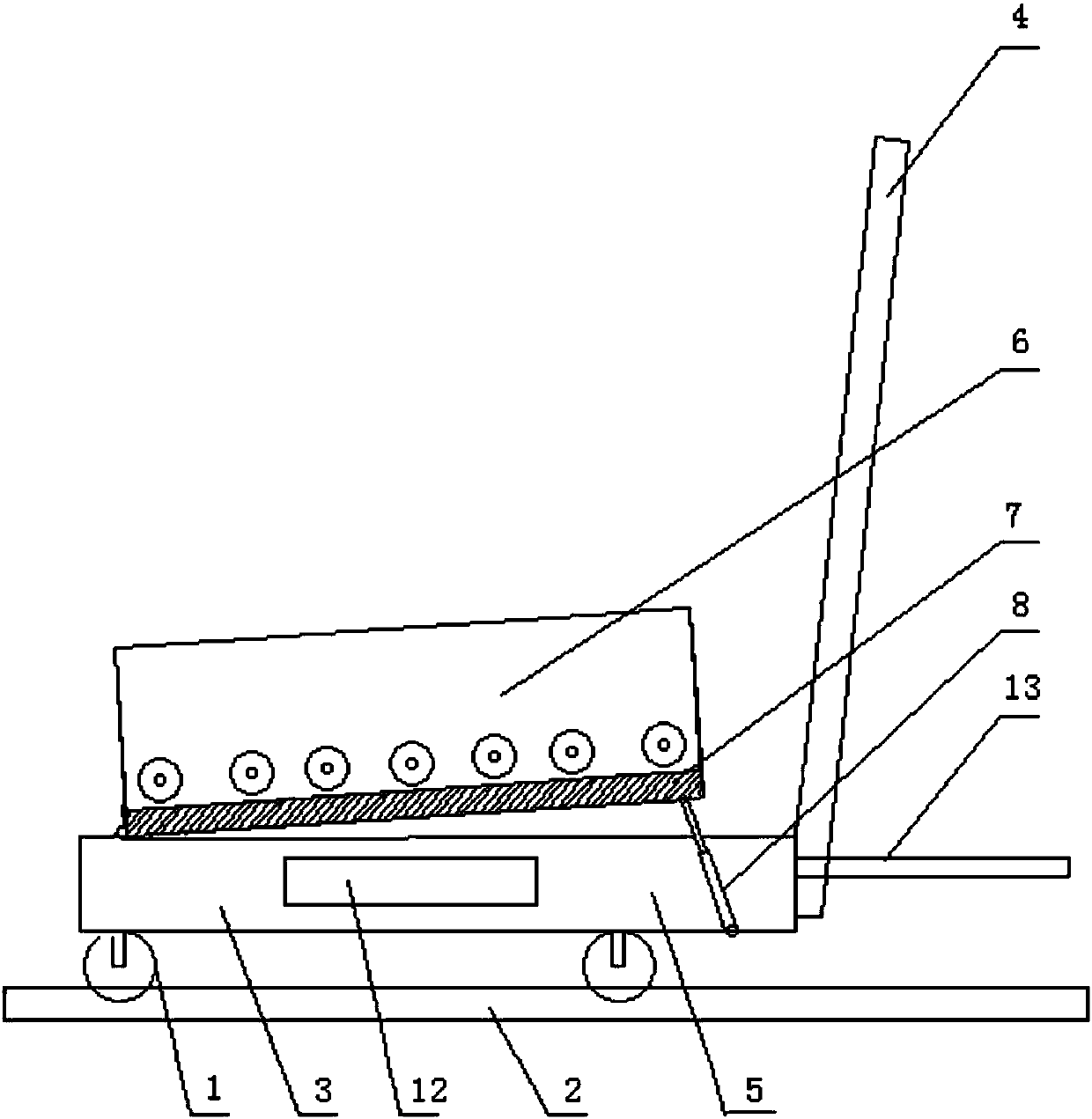

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] Such as Figure 1-3 As shown, the glass fiber cloth roll rail transport vehicle of the present invention drives the wheels 1 to move along the track 2 through a motor, and includes a chassis 3 and an auxiliary support frame. One end of the chassis 3 is fixed with a handle 4, and the bottom of the handle 4 is The horizontal carriage 13 is fixed on the side of the frame 3; the auxiliary support frame includes a base plate 5 and guard plates 6 fixed on both sides of the base plate 5, and multiple groups of drive rollers 7 arranged at intervals in parallel are set between the guard plates 6; the base plate The first end of 5 is hinged with the underframe 3, and an electric push rod 8 is arranged between the second end of the bottom plate 5 and the underframe 3; the bottom end of the electric push rod 8 is hinged with the underframe 3, and the top end of the electric push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com