Multifunctional single-spike rice threshing machine

A threshing machine, multi-functional technology, applied in threshing equipment, agricultural machinery and tools, applications, etc., can solve the problems of poor threshing quality, inconvenient operation, complex structure, etc., and achieve good threshing quality, convenient operation, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

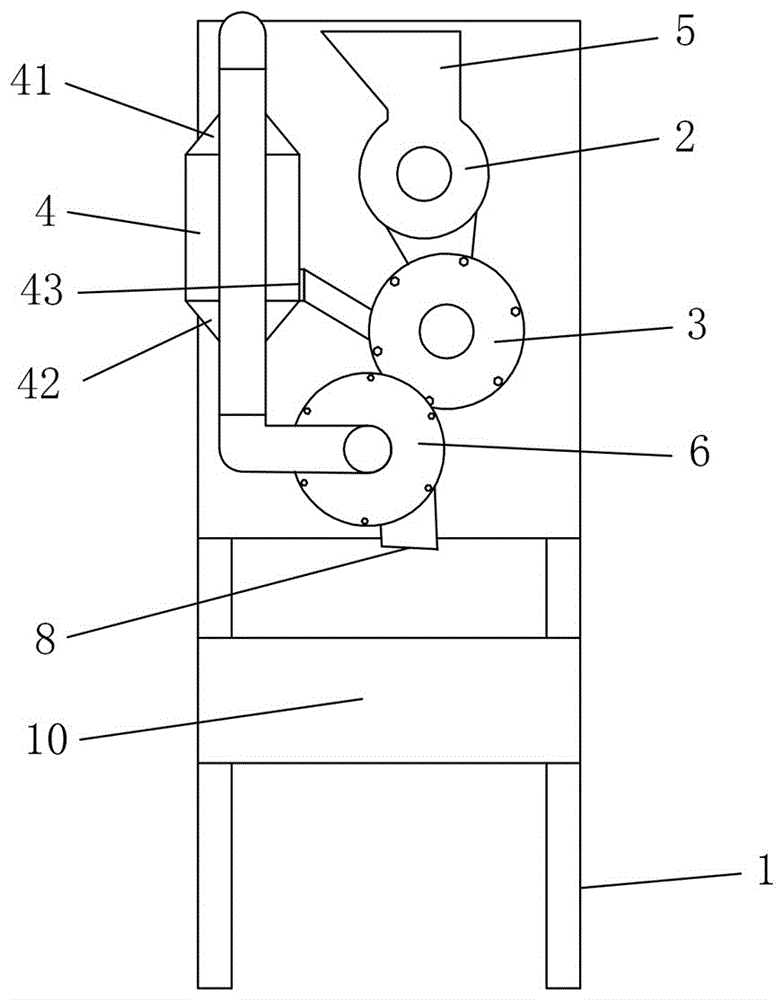

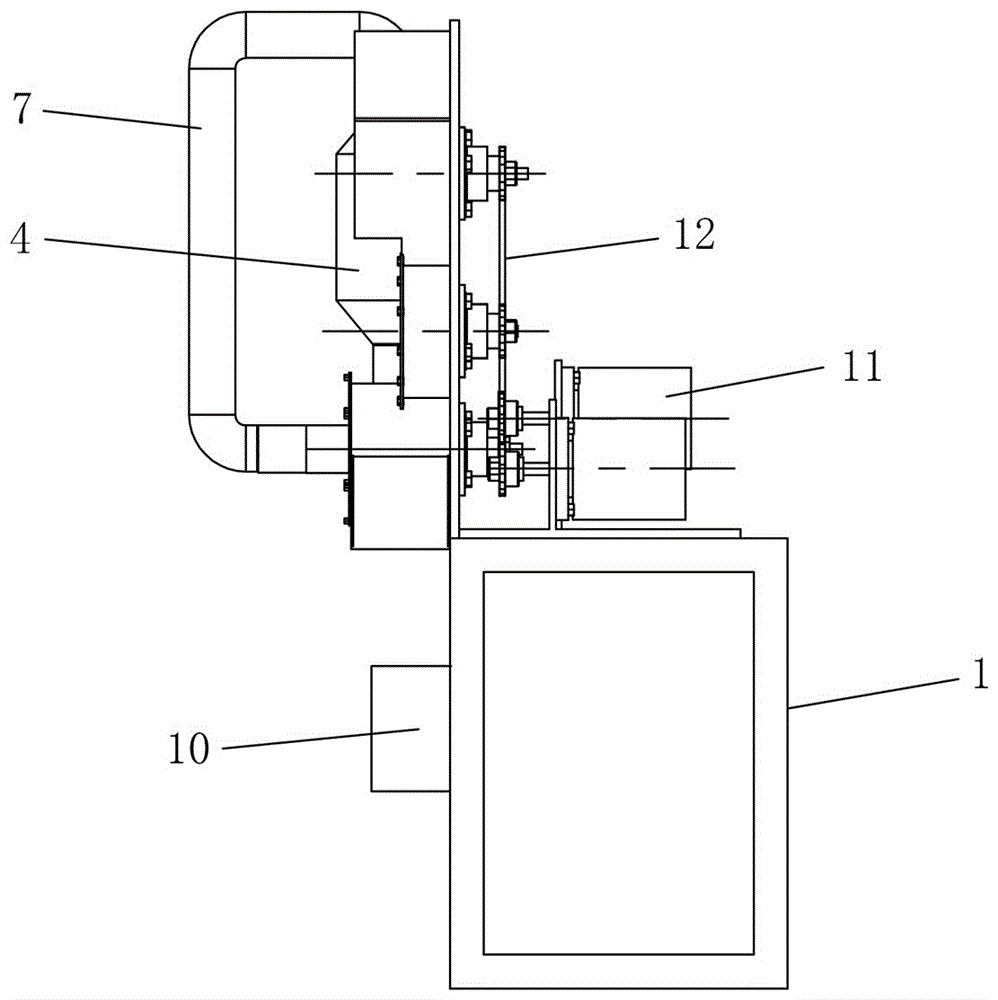

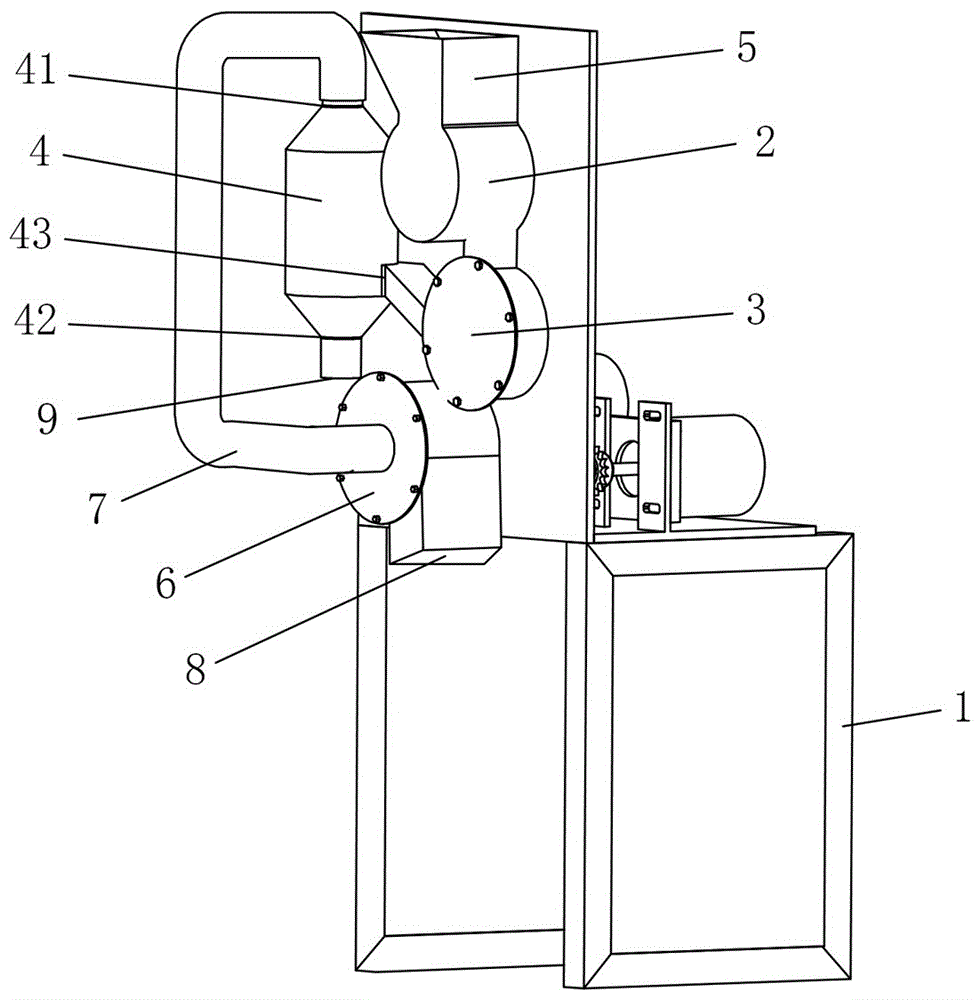

[0019] Such as Figure 1 to Figure 3 As shown, the multifunctional single-ear rice thresher of the present embodiment comprises a frame 1, and the frame 1 is provided with a threshing chamber 2 with a threshing cylinder inside, a material receiving chamber 3 with a rotating twist piece inside, an air-flow type Separate the material cylinder 4 and the driving mechanism used to drive the threshing drum and the rotary blade to rotate. The top of the threshing chamber 2 is provided with a feeding hopper 5, and the material receiving chamber 3 communicates with the bottom of the threshing chamber 2. The airflow type separates the material cylinder 4 is provided with the top outlet 41 that is positioned at the top, the bottom outlet 42 that is positioned at the bottom and the side inlet 43 that is positioned at the side, side inlet 43 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com