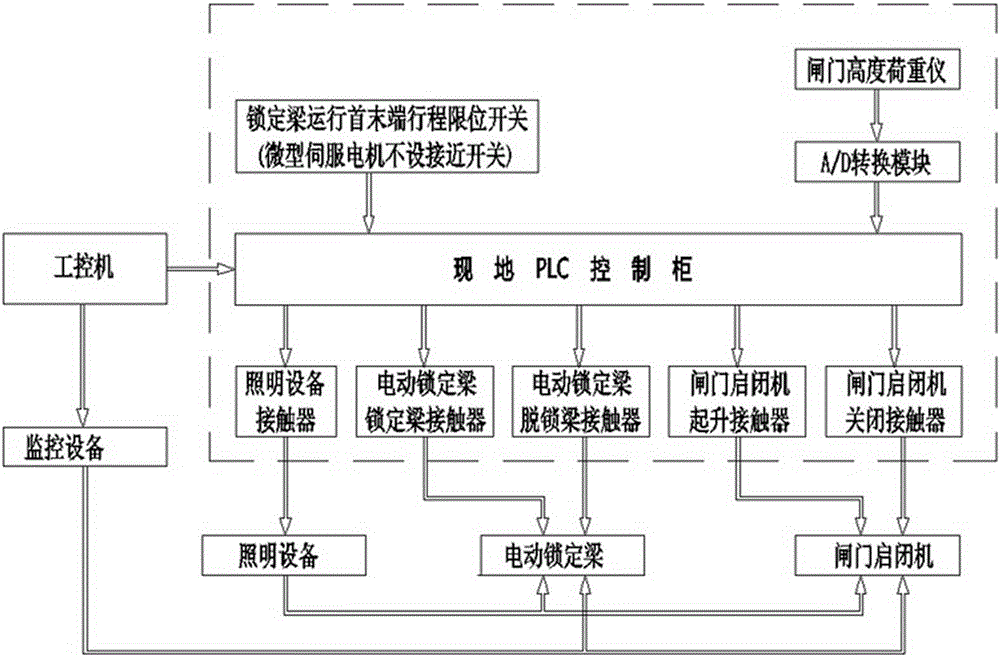

In-situ and remote full-automatic control system of gate hoist

A control system and gate hoist technology, applied in water conservancy projects, sea area projects, artificial waterways, etc., can solve problems such as inability to achieve centralized and remote control, reduce operating personnel and operating costs, avoid occurrence and expansion, and operate safely Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

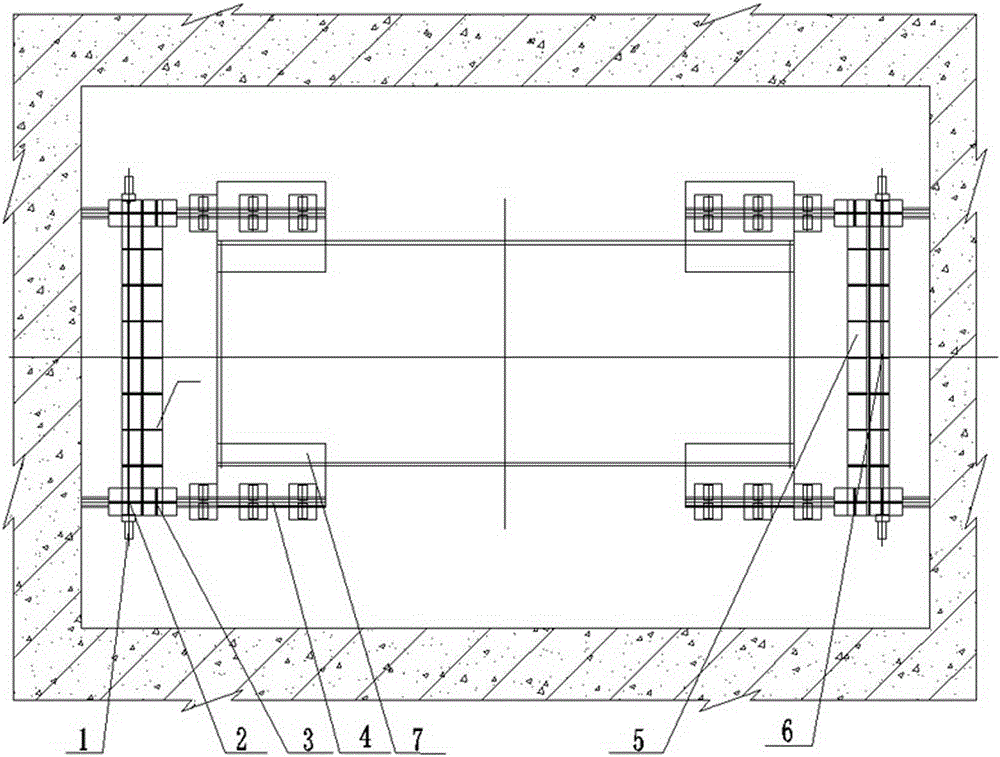

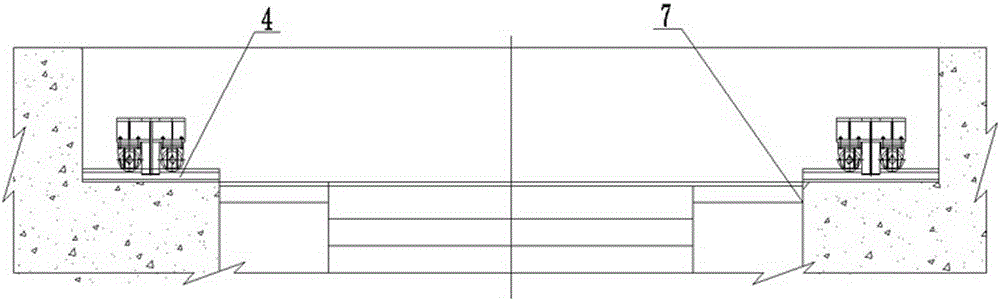

Examples

Embodiment 1

[0029] The lock beam of the inlet and outlet gates of a power station diversion canal weighs 120kg, and the walking mechanism weighs 120kg. The track model is 9kg / m, the wheel diameter of the running mechanism:, the running speed is ~1.5m / min, and the electric speed is 1320 rpm.

[0030] Set to reach the design speed from the start acceleration state within 1 second:

[0031] Moment of inertia: J=mR*R / 2=0.768;

[0032] Angular acceleration: α=n*360 / 57.3 / 60=138.22;

[0033] Torque: T=J*α=106.15NM;

[0034] Power: P=T*n / 9550=14.67W;

[0035] Taking the motor service coefficient as 1.5, the motor power can be initially determined as 14.67*1.5=22w;

[0036] Check the selection data of the micro motor: select the motor as 25w, select 1:10 for the middle gearbox, and 1:60 for the right-angle medium and real gearbox;

[0037] Operating speed of the operating mechanism: 1.105m / min;

[0038] Finally, the motor and its deceleration mechanism model: 25YS120DV.

[0039] The weight of the electric lockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com