Conveyor capable of achieving steering and overturning of finished cigarette box

A technology of conveyors and smoke boxes, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing material consumption, large manpower and material resources, and reducing the efficiency of logistics systems, so as to ensure work efficiency and convey The process is stable and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

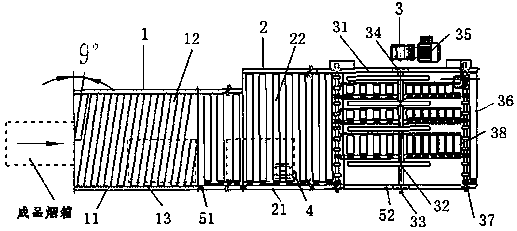

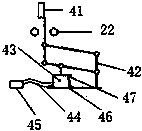

[0023] Such as Figure 1 to Figure 4 As shown, the conveyor capable of turning and overturning the finished cigarette boxes includes a skewed roller conveying device 1 for arranging the incoming cigarette boxes in a straight line, and is used to accept the cigarette boxes sent out by the skewed roller conveying device 1 and continue to The vertical roller conveying device 2 for front conveying, the cigarette case steering device 4 for guiding and turning the cigarette cases transported on the vertical roller conveying device 2, and the cigarette case for receiving the cigarette cases sent out by the vertical roller conveying device 2 and being able to The overturning conveying devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com