Cutting and laminating device for processing water purification filter element

一种水净化、裁切的技术,应用在运输和包装、卷绕条材、发送物件等方向,能够解决工作效率低等问题,达到提高生产效率、高自动化水平、结构设计巧妙的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

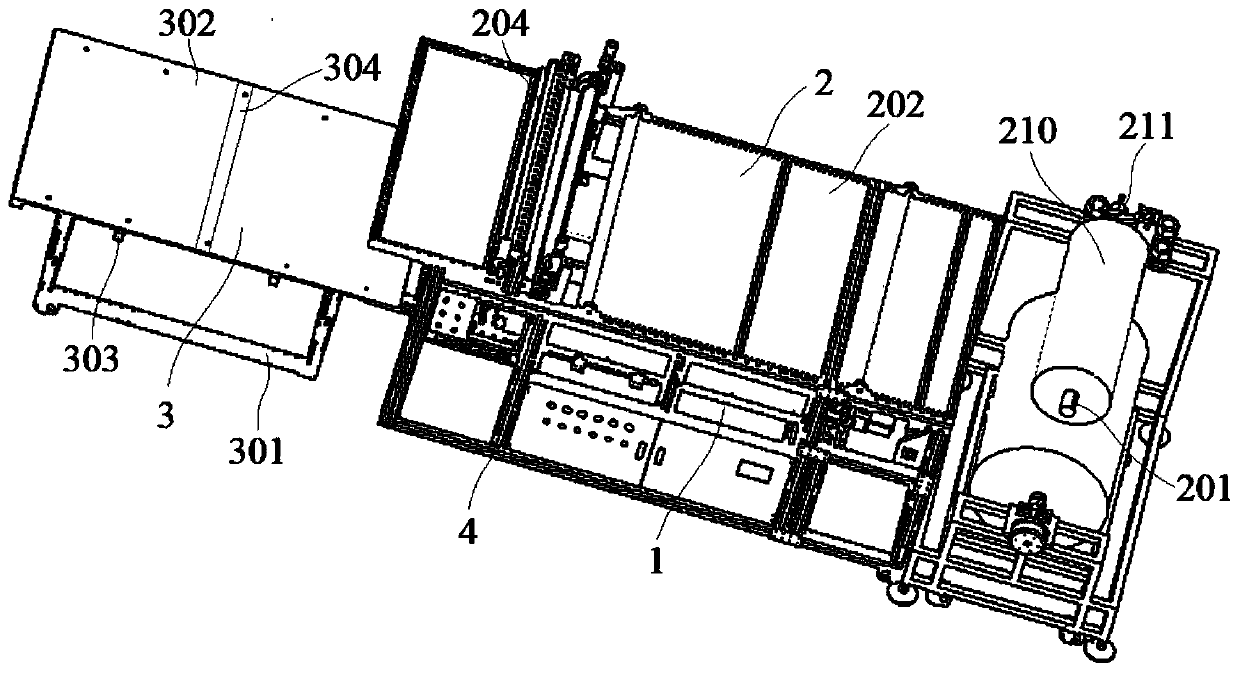

[0033]Embodiment 1: A cutting and laminating device for water purification filter core processing, including a first cutting mechanism 1, a second cutting mechanism 2, a stacking mechanism 3 and a frame 4, the first cutting mechanism 1 and The second cutting mechanism 2 is installed on the frame 4, the first cutting mechanism 1 is located directly below the second cutting mechanism 2, and the stacking mechanism 3 is arranged on the first cutting mechanism 1 and the second cutting mechanism. The rear side of the cutting mechanism 2;

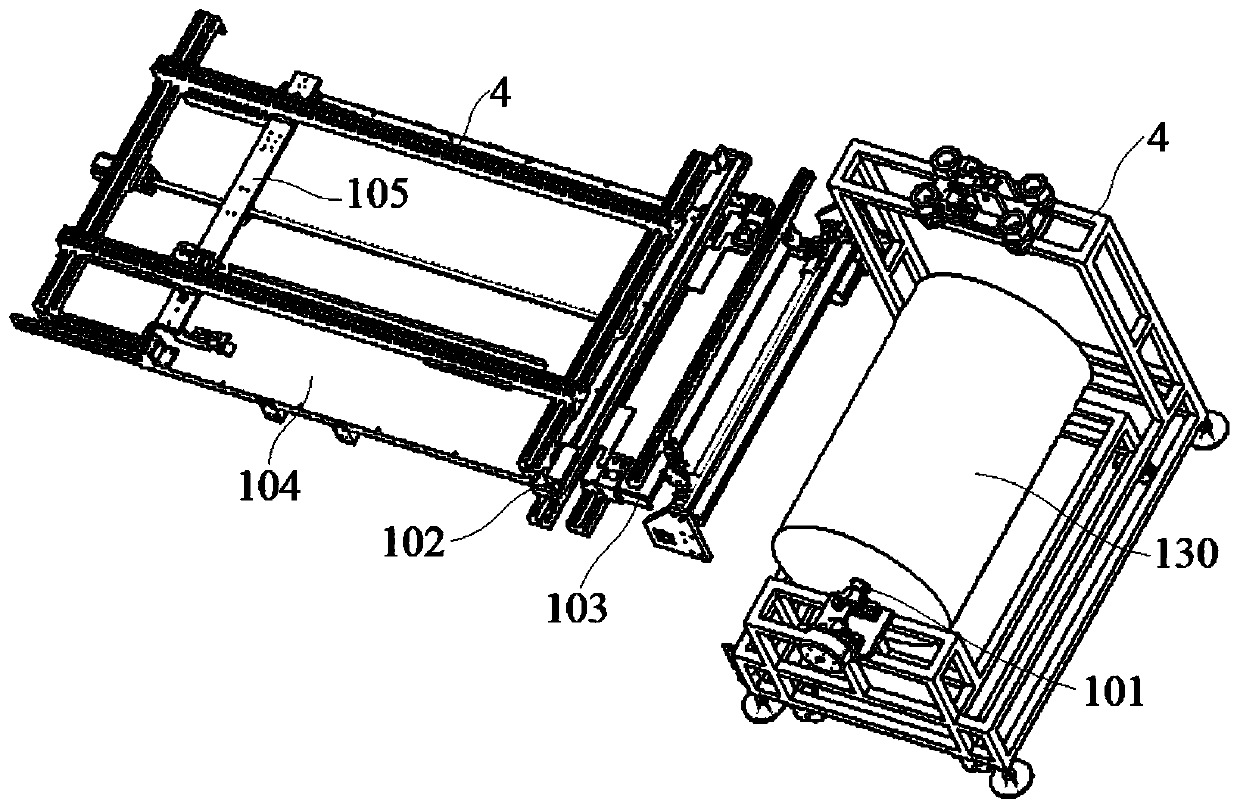

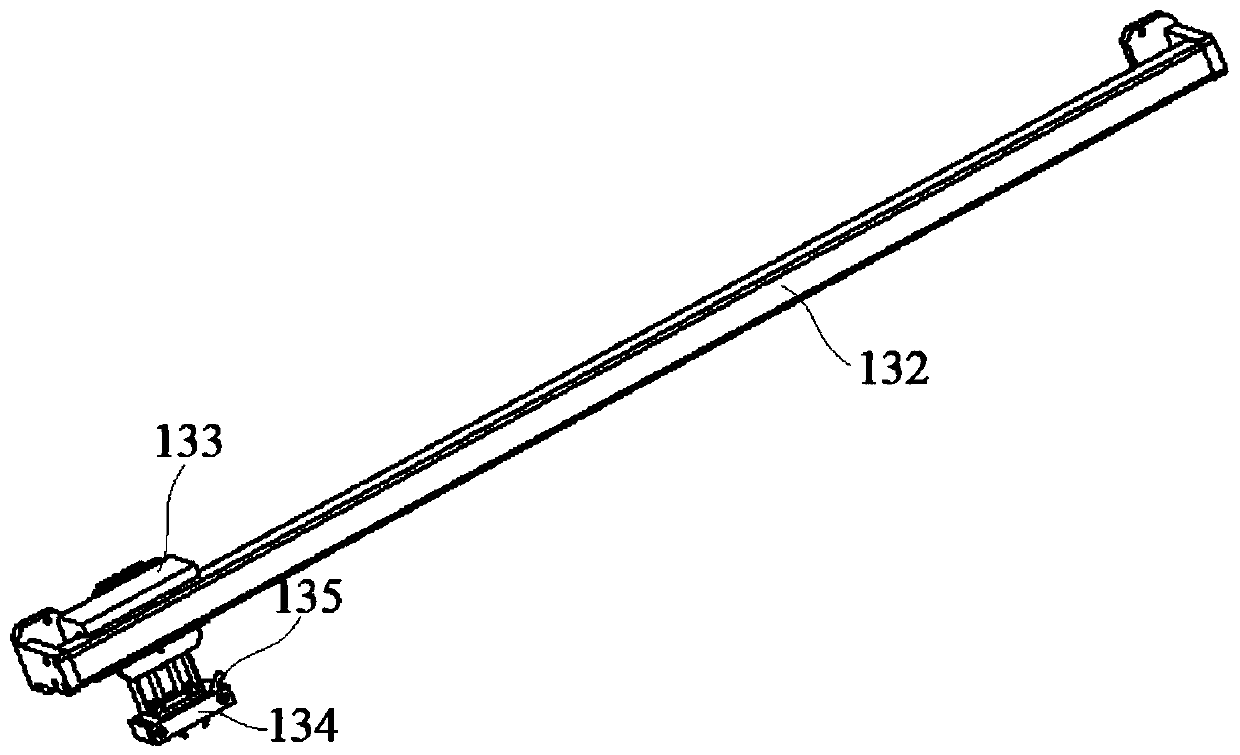

[0034] The first cutting mechanism 1 further includes a first installation cylinder 101, a film cutting mechanism 102, a film pressing mechanism 103, a movable carrier 104 and a first driving mechanism 105, and the first installation cylinder 101 is arranged at the front end of the frame 4 , the first driving mechanism 105 is arranged on the rear end of the frame 4, the movable carrier 104 is installed on the frame 4, and the film cutting mechanis...

Embodiment 2

[0046] Embodiment 2: A cutting and laminating device for water purification filter element processing, including a first cutting mechanism 1, a second cutting mechanism 2, a stacking mechanism 3 and a frame 4, the first cutting mechanism 1 and The second cutting mechanism 2 is installed on the frame 4, the first cutting mechanism 1 is located directly below the second cutting mechanism 2, and the stacking mechanism 3 is arranged on the first cutting mechanism 1 and the second cutting mechanism. The rear side of the cutting mechanism 2;

[0047] The first cutting mechanism 1 further includes a first installation cylinder 101, a film cutting mechanism 102, a film pressing mechanism 103, a movable carrier 104 and a first driving mechanism 105, and the first installation cylinder 101 is arranged at the front end of the frame 4 , the first driving mechanism 105 is arranged on the rear end of the frame 4, the movable carrier 104 is installed on the frame 4, and the film cutting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com