Palletizing equipment for battery processing

A battery and palletizing technology, which is applied in the field of palletizing equipment for battery processing, can solve the problems of easy falling of batteries, and achieve the effect of preventing battery from falling and preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

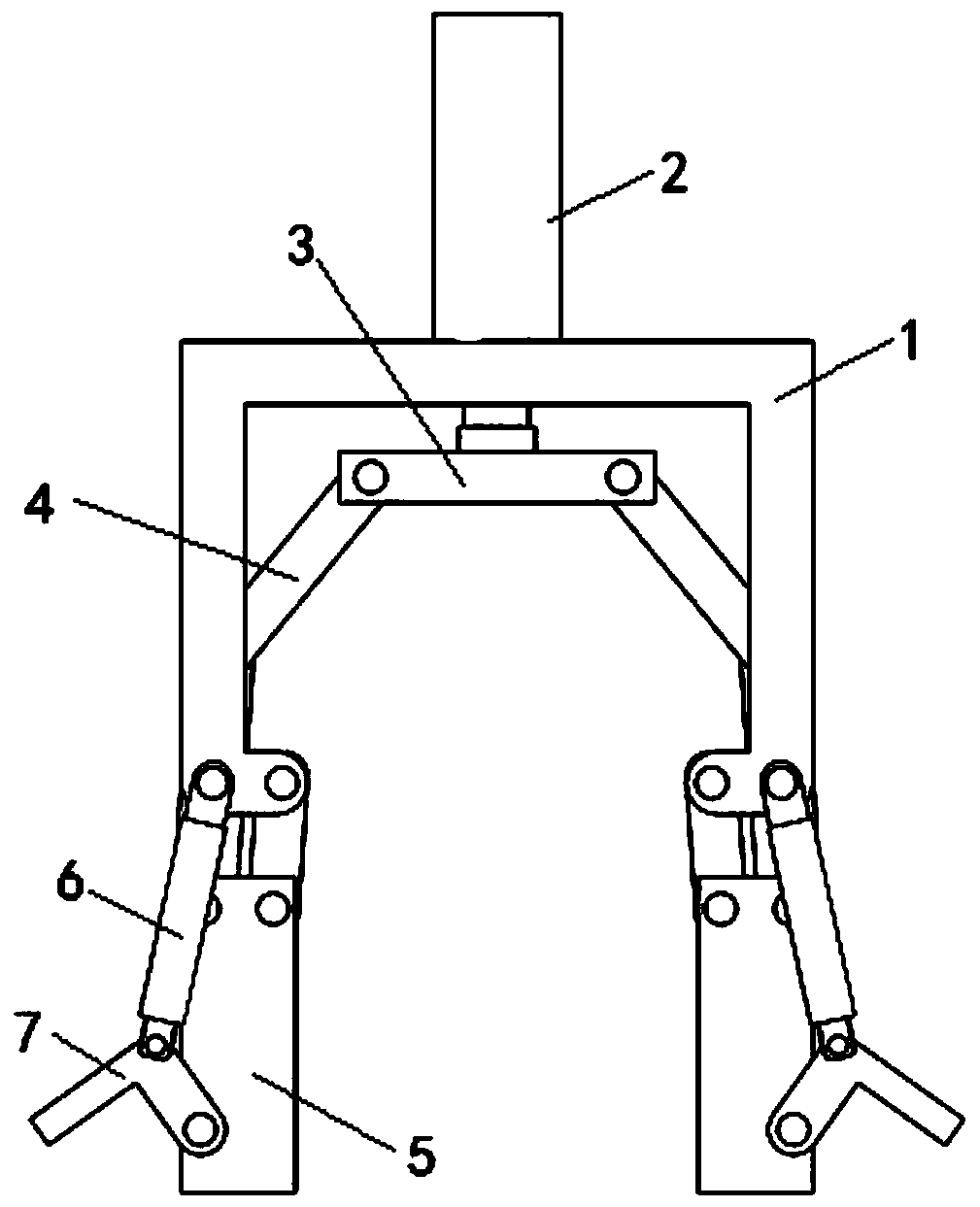

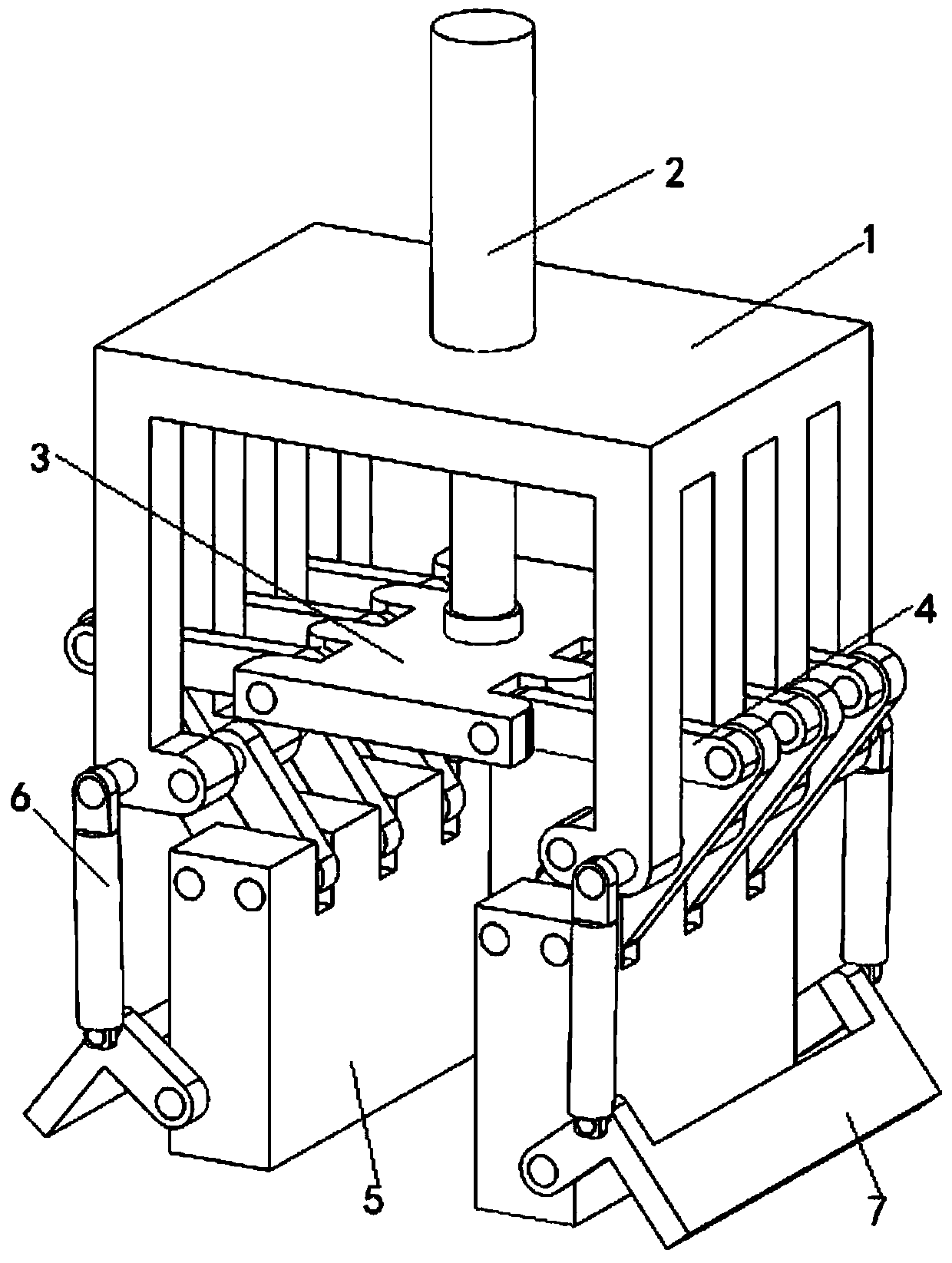

[0024] A palletizing equipment for battery processing, such as Figure 1-4 As shown, it includes the battery clamping and fixing device. After the battery is clamped and fixed by the battery clamping and fixing device, it moves to the stacking position under the movement of the manipulator, and then the batteries on the clamping device are stacked together. The battery clamp The holding and fixing device includes the jaw fixing seat 1 and the hydraulic cylinder 2 installed on the top of the jaw fixing seat 1. At the same time, the power output end of the hydraulic cylinder 2 is installed with a limit push-pull seat 3. A connecting rod clamping mechanism 4 is installed between them, and the bottom end of the connecting rod clamping mechanism 4 is equipped with a compression fixing plate 5. The bottom of the 5 is equipped with a bottom stop seat 7, and the two sides of the bottom stop seat 7 are installed on the adjustment hydraulic cylinder 6;

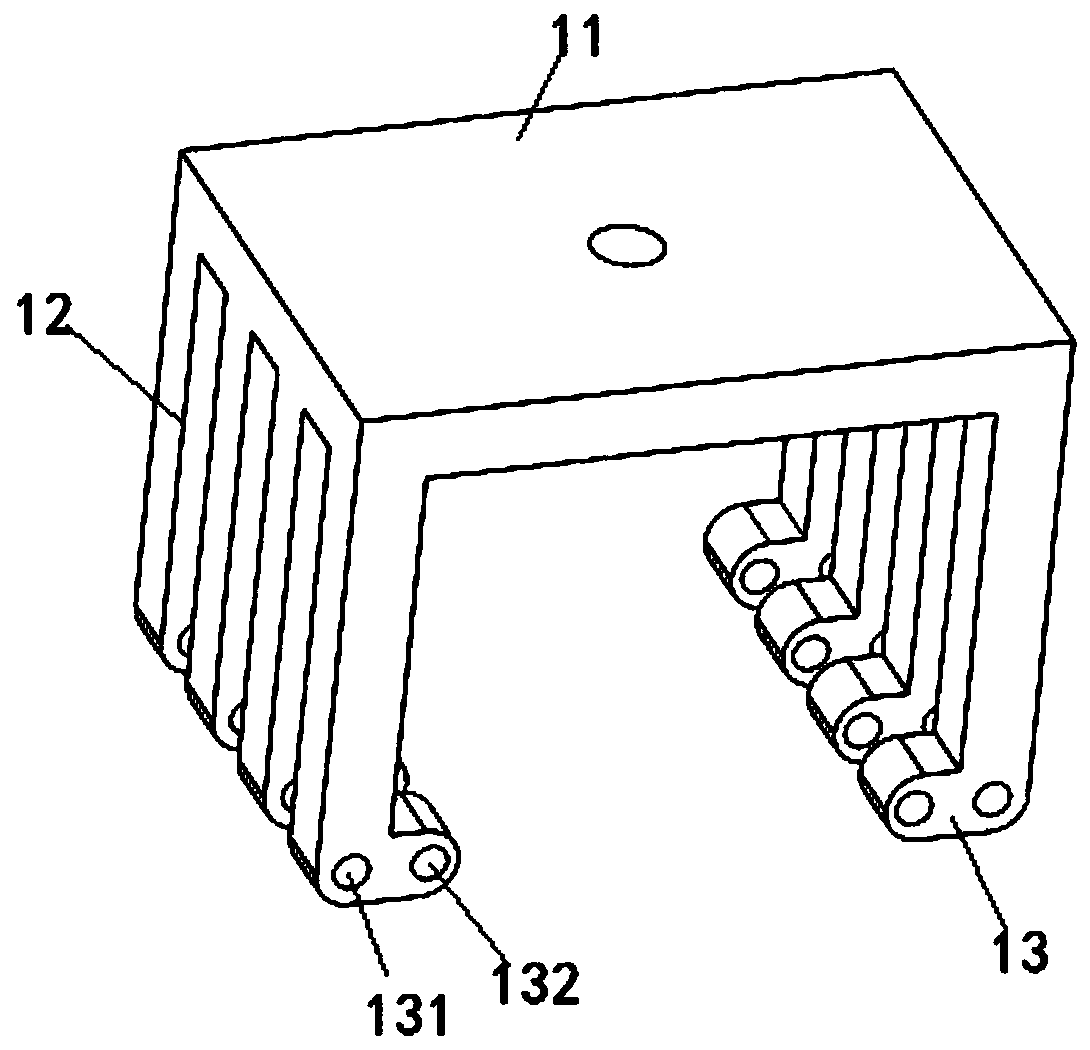

[0025] Such as Figure 5 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com