Induction coil heating device

A heating device, induction coil technology, applied in the direction of induction heating device, coil device, induction heating, etc., can solve the problems of burnt black, easy carbonization of the appearance surface, etc., and achieve the best quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

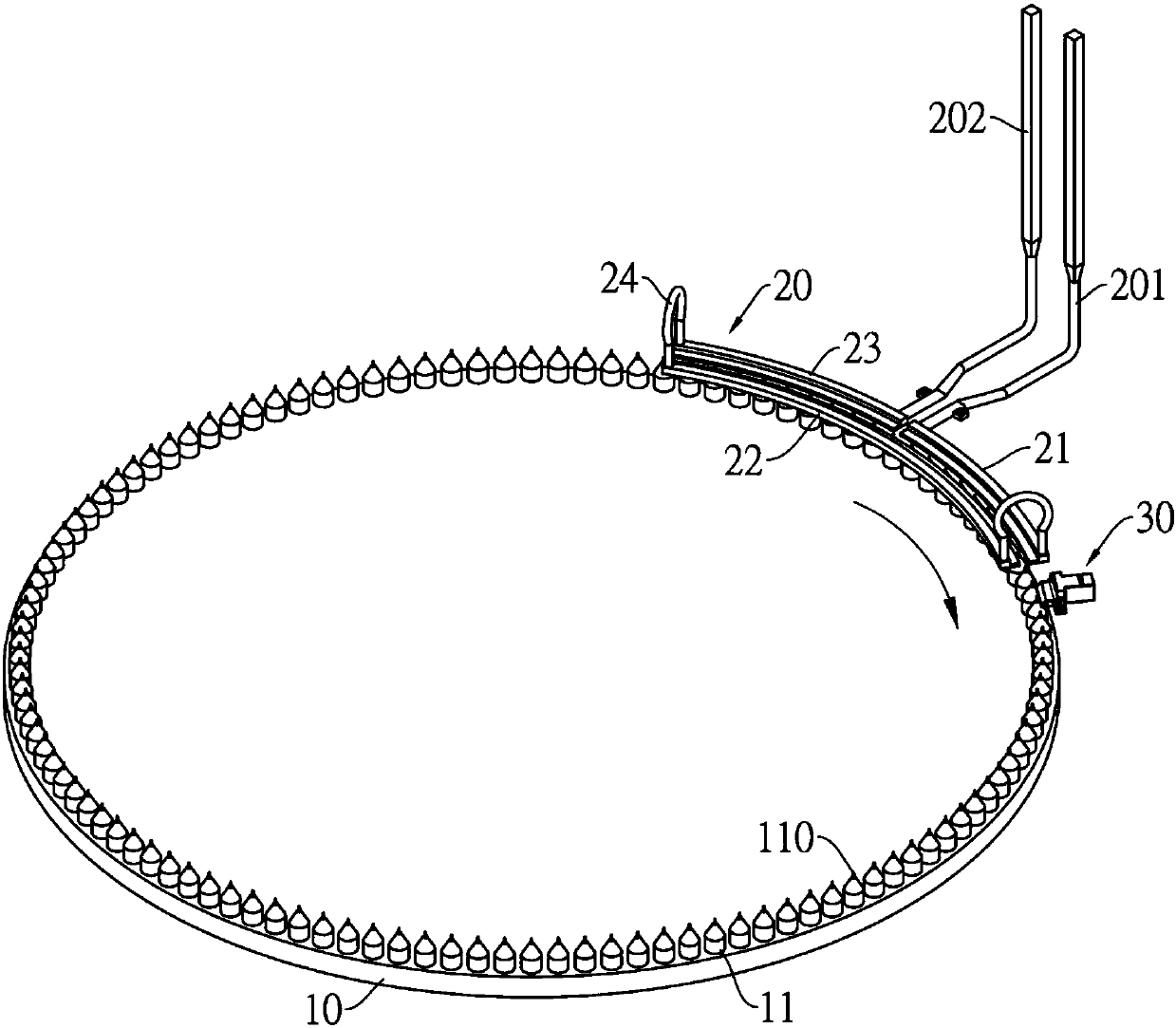

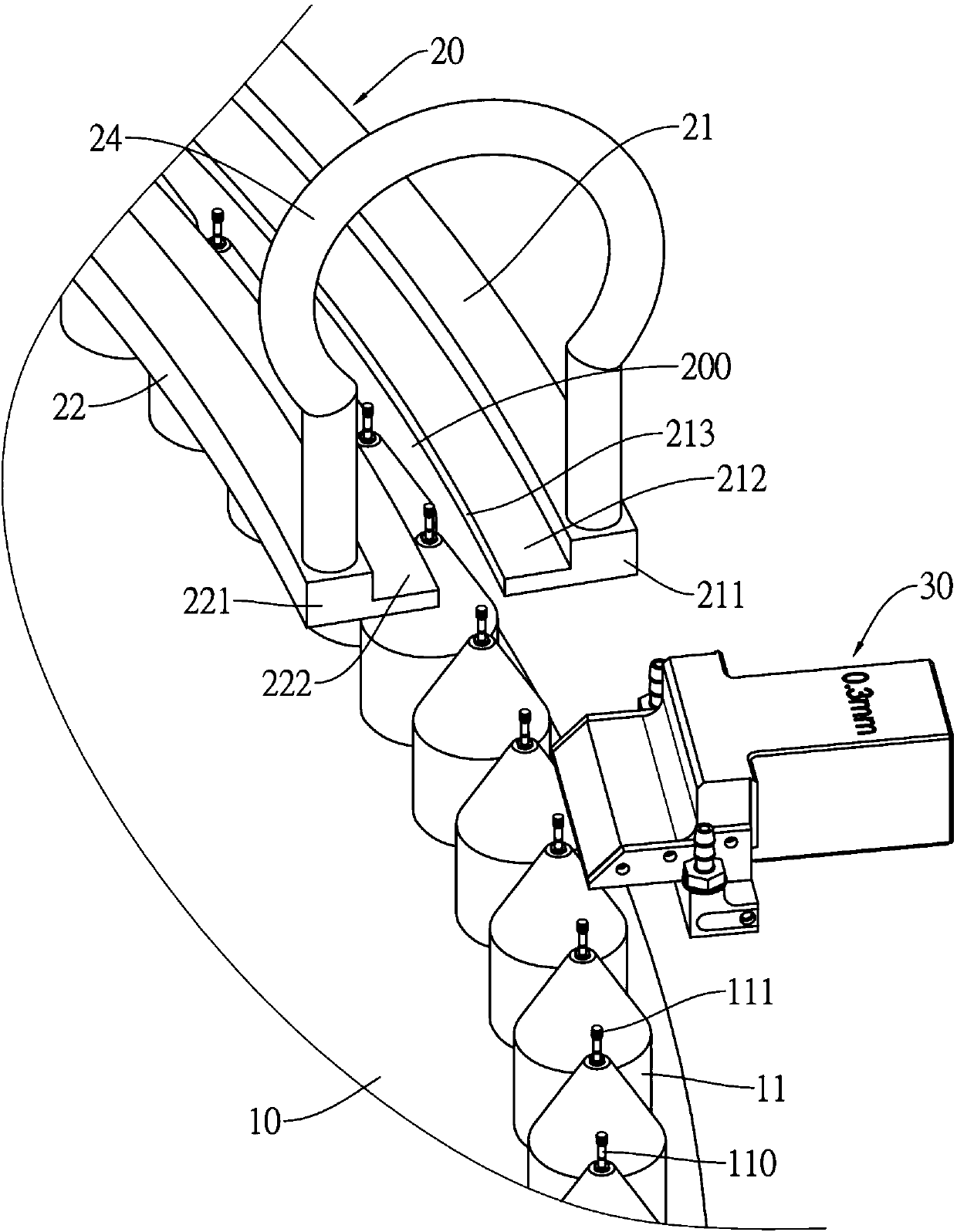

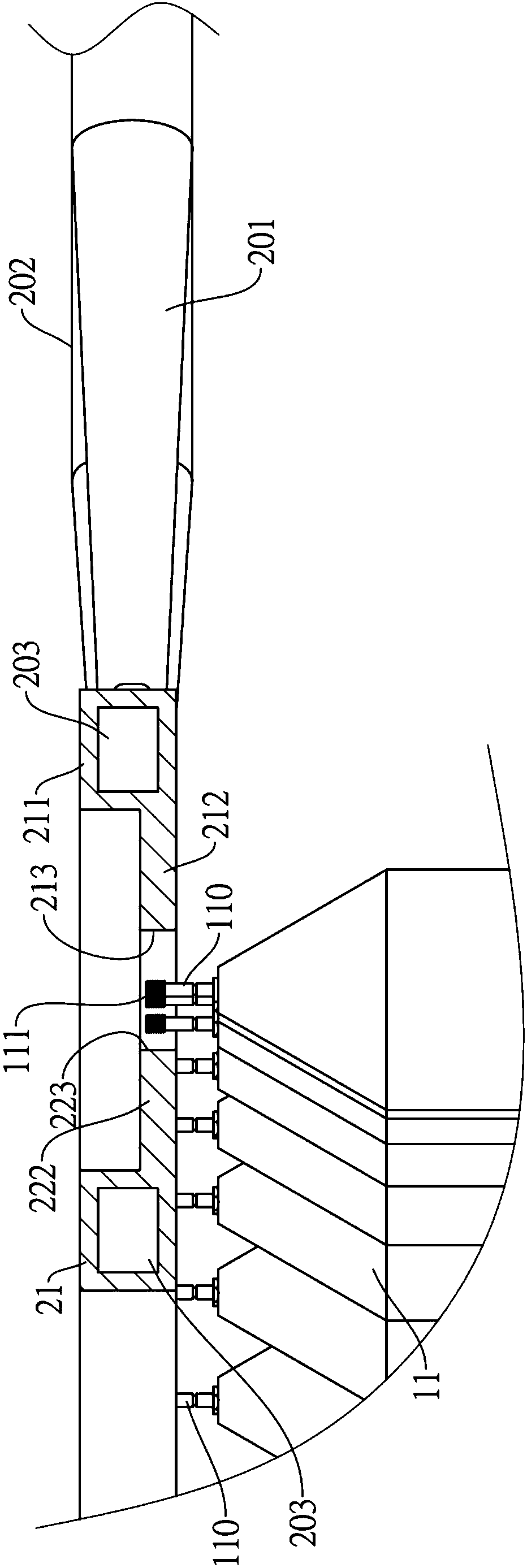

[0028] see figure 1 and figure 2 As shown, the present invention is an induction coil heating device, which includes a working turntable 10 and an induction electromagnetic heating group 20, the working turntable 10 and the induction electromagnetic heating group 20 can be installed on a frame, and the frame is an existing There are technologies, not shown in the figure. The working turntable 10 is connected to the drive shaft of a motor, and the motor is arranged on the frame to drive the working turntable 10 to rotate. Tool 11, each of the fixtures 11 can carry the screws 110 to be processed respectively, that is to say, the screws 110 to be processed can be transported to the corresponding fixture 11 from a feed end in sequence, and after the processing is completed, a The material ends leave the jig 11 in sequence.

[0029] The induction electromagnetic heating group 20 can be a strip body and is arranged on the action path position of each fixture 11, and a coil chann...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap