Aluminum-plastic panel production technology

A production process and technology for aluminum-plastic panels, applied in the field of aluminum-plastic panel production and manufacturing, can solve problems affecting work efficiency, loose installation positions, and inability to accurately control the distance adjusted by the processing roller head, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

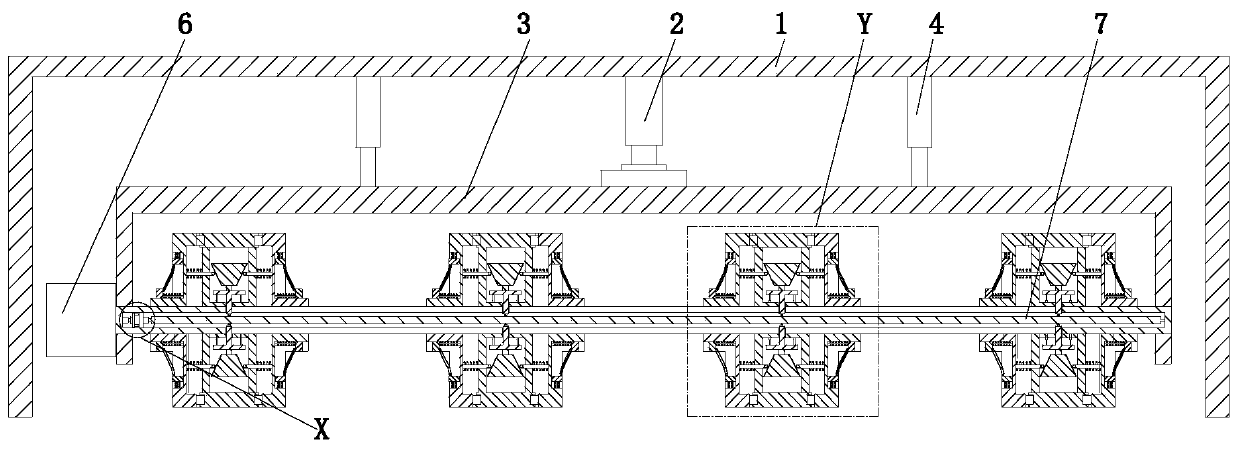

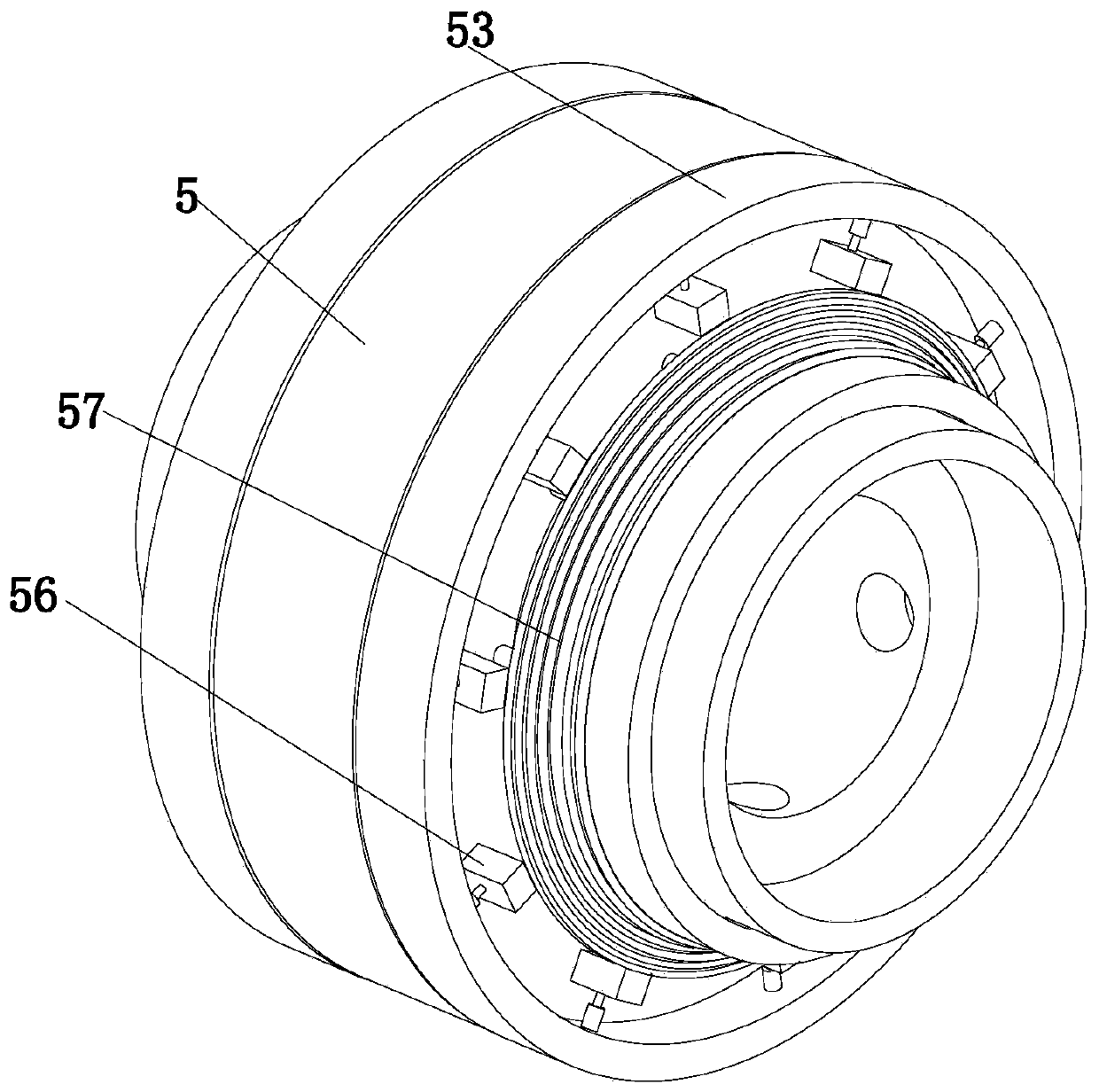

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

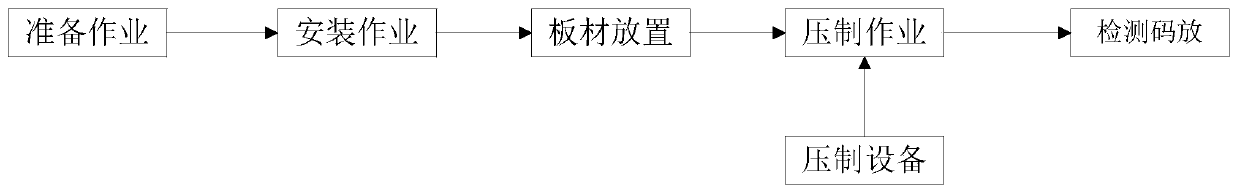

[0036] Such as Figure 1 to Figure 9 As shown, an aluminum-plastic panel production process mainly includes the following production steps:

[0037] Package step 1, prepare for the operation, determine the size of the processing roll according to the processing requirements, select the forming mold of the corresponding size, and fix the forming mold on the working position;

[0038] Step 2, installation work, fix the pressing equipment on the mobile machine, install the mobile machine with the pressing equipment on the designated working position, manually control the pressing equipment to automatically adapt and adjust according to the specifications of the forming mold, so that the pressing equipment and the forming Molds can cooperate with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com