Flanging and bottom sealing production technology

A production process and back-sealing technology, applied in the field of flanging and back-sealing production processes, can solve problems such as affecting production progress, complex process routes, and wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

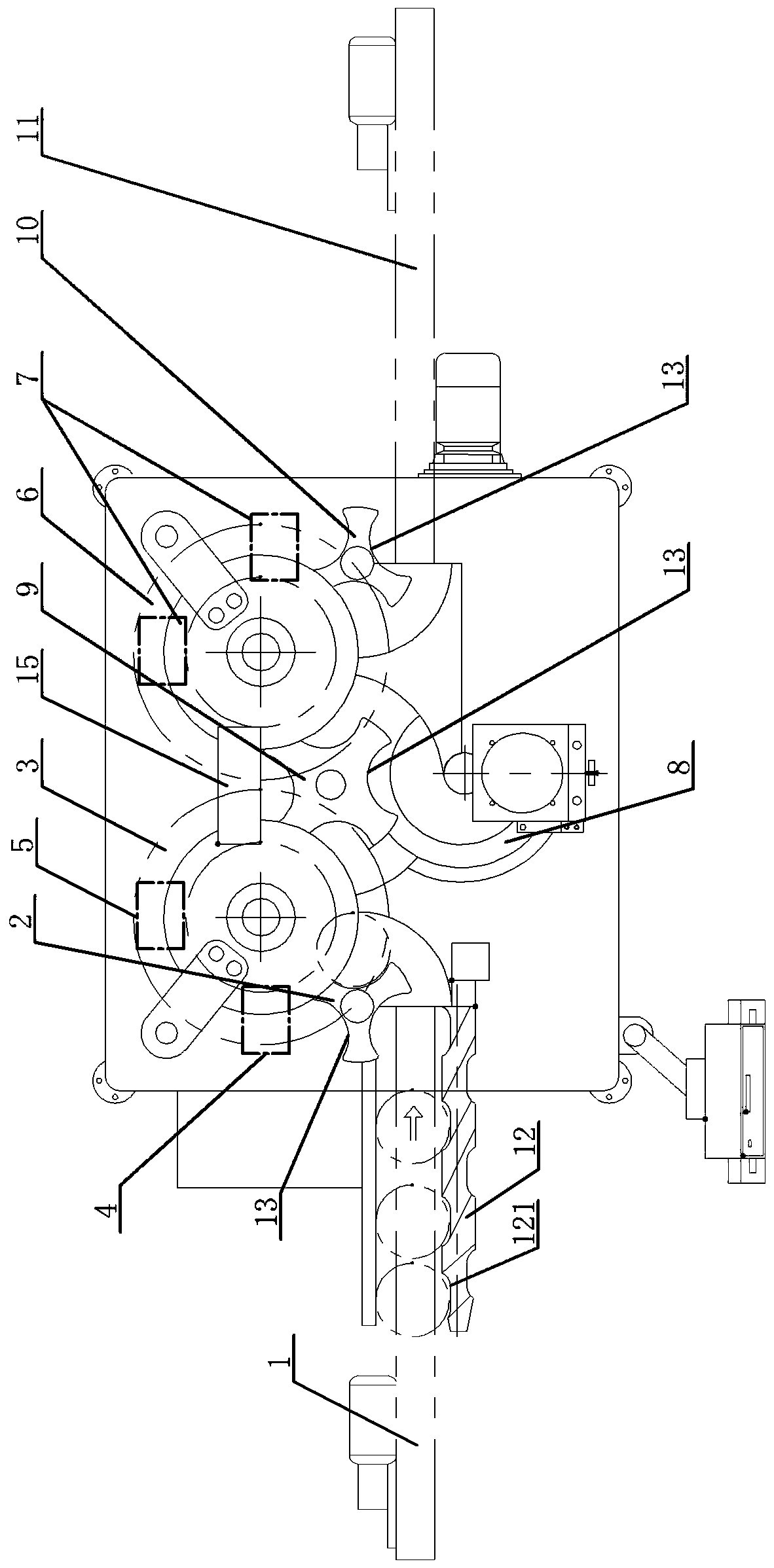

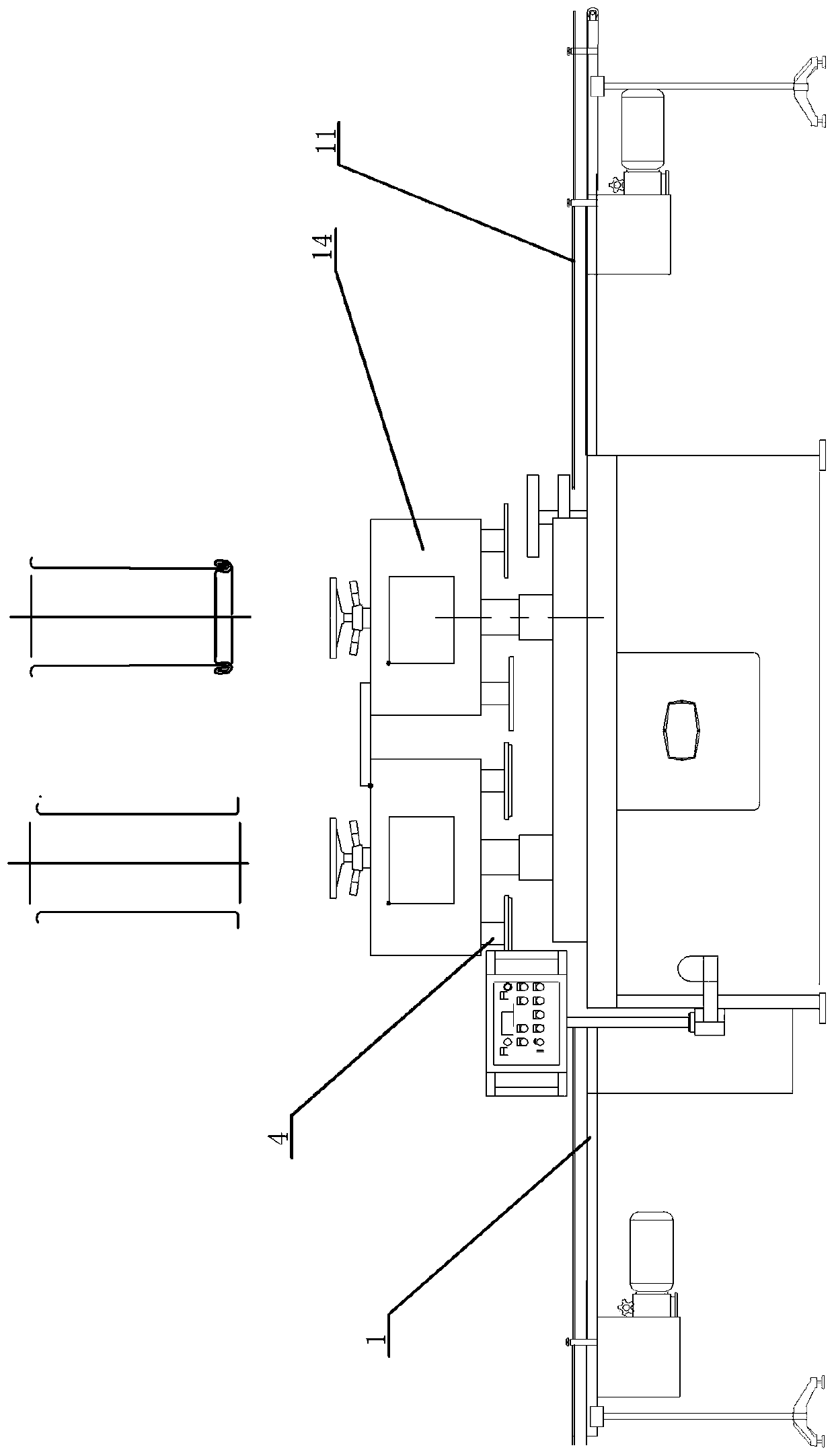

[0017] A flanging back cover production process, see figure 1 , figure 2 : Convey the rounded can body along the first can body conveying line 1, and then transport the can body to the first disc conveying line 3 through the first can feeding star wheel 2, the first disc conveying line 3 Step feeding, the position of the first disc conveying line 3 corresponds to the flanging station, and the stepping positions of the outer ring conveying area of the first disc conveying line 3 are respectively arranged with an upper flanging station 4, a lower flanging station The flanging structure corresponding to the edge station 5, the upper flanging station 4, and the lower flanging station 5 is a multi-roller crimping structure, and the second disc conveying line is arranged on the side of the first disc conveying line 3. Line 6, the second disc conveying line 6 step feeding, the position of the second disc conveying line 6 corresponds to at least two back cover stations 7, the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com