Preparation method of PDCPD raw material containing cyclopentadiene tripolymer

A technology of cyclopentadiene and dicyclopentadiene is applied in the field of preparation of PDCPD raw materials, can solve the problems of low reaction yield, high production cost, reduced yield and the like, achieves simple and reliable process route, reduced side reactions, Reduce the effect of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

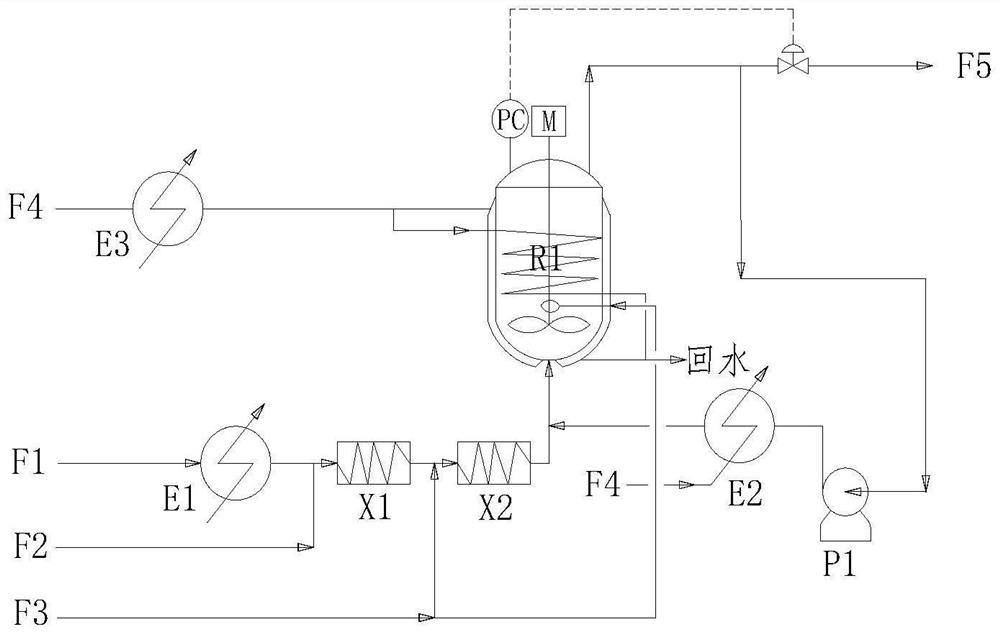

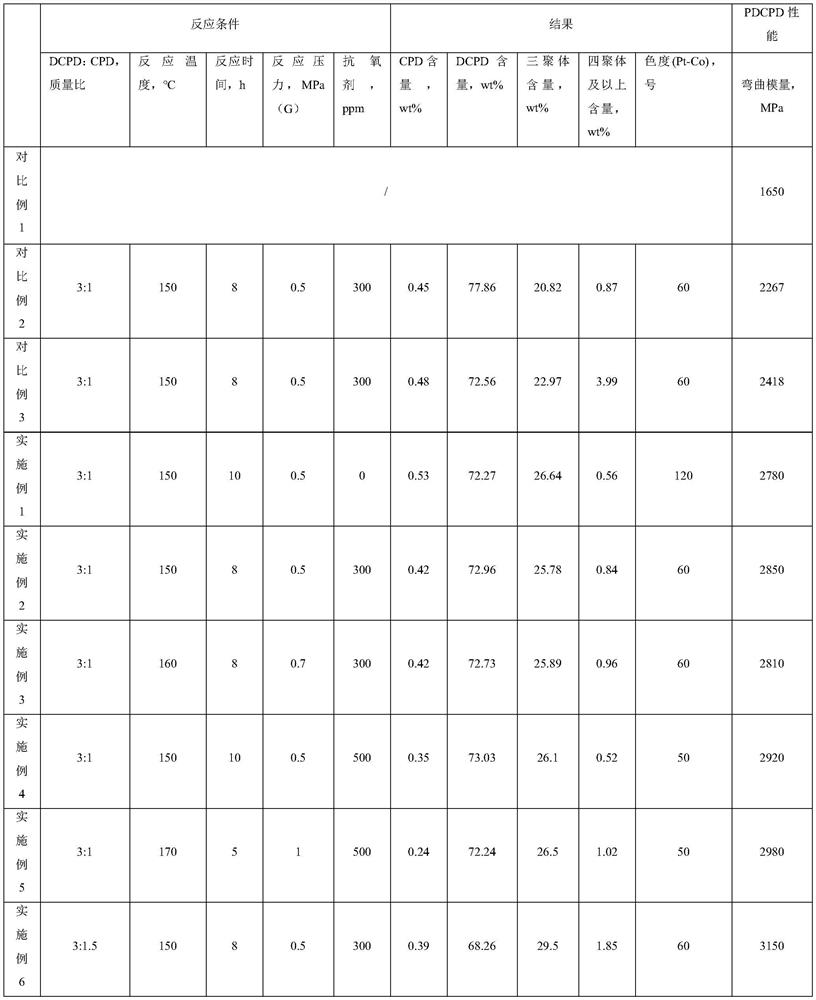

Embodiment 1

[0047] After the dicyclopentadiene feedstock F1 is preheated to 100°C by the feed heater E1, it is mixed with the cyclopentadiene feedstock F3 from the depolymerization unit at a mass ratio of 3:0.5 in the mixer X2. The mixed material is mixed with the pressurized material from the circulating pump P1. The mixing ratio is fresh feed: the mass ratio of circulating material is 1:20. The mixed material enters the polymerization reactor R1, while the second strand of cyclopentadiene is mixed. Material F3 (with a mass ratio of DCPD of 3:0.5) is injected at the stirring paddle of the polymerization reactor R1, and the polymerization reaction is carried out in the polymerization reactor R1. The device E3 controls the hot water F4 fed into the stirred tank R1 at 150°C, the polymerization residence time is controlled by the feed flow to 10h, and the reactor pressure is controlled by the control valve to be 0.5Mpa. Material F5 is produced from the top of the polymerization kettle throug...

Embodiment 2

[0051] After the dicyclopentadiene raw material F1 is preheated to 100 ℃ by the feed heater E1, it is mixed with the antioxidant F2 in the mixer X1. The amount of the antioxidant added is 300ppm of the total fresh feed. The incoming cyclopentadiene material F3 is mixed in the mixer X2 in a mass ratio of 3:0.5. The mixed material is mixed with the pressurized material from the circulating pump P1. The mixing ratio is fresh feed: the mass ratio of circulating material is 1:20. The mixed material enters the polymerization reactor R1, while the second strand of cyclopentadiene is mixed. The material (with a mass ratio of DCPD of 3:0.5) was injected at the stirring paddle of the polymerization reactor R1, and the polymerization reaction was carried out in the polymerization reactor R1. At the same time, the polymerization stirring speed was set to 98r / min, and the polymerization reaction temperature was controlled by the hot water system. At 150°C, the polymerization residence time...

Embodiment 3

[0055] After the dicyclopentadiene raw material F1 is preheated to 100 ℃ by the feed heater E1, it is mixed with the antioxidant F2 in the mixer X1. The amount of the antioxidant added is 300ppm of the total fresh feed. The incoming cyclopentadiene material F3 is mixed in the mixer X2 in a mass ratio of 3:0.5. The mixed material is mixed with the pressurized material from the circulating pump P1. The mixing ratio is fresh feed: the mass ratio of circulating material is 1:20. The mixed material enters the polymerization reactor R1, while the second strand of cyclopentadiene is mixed. The material (with a mass ratio of DCPD of 3:0.5) was injected at the stirring paddle of the polymerization reactor R1, and the polymerization reaction was carried out in the polymerization reactor R1. At the same time, the polymerization stirring speed was set to 98r / min, and the polymerization reaction temperature was controlled by the hot water system. At 160°C, the polymerization residence time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com