The production method of 5-ethylidene-2-norbornene enb

A production method and a norbornene technology are applied in the production field of 5-ethylidene-2-norbornene ENB, can solve the problems of high energy consumption, low product purity and the like, and achieve low energy consumption, high product purity, The effect of fewer by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

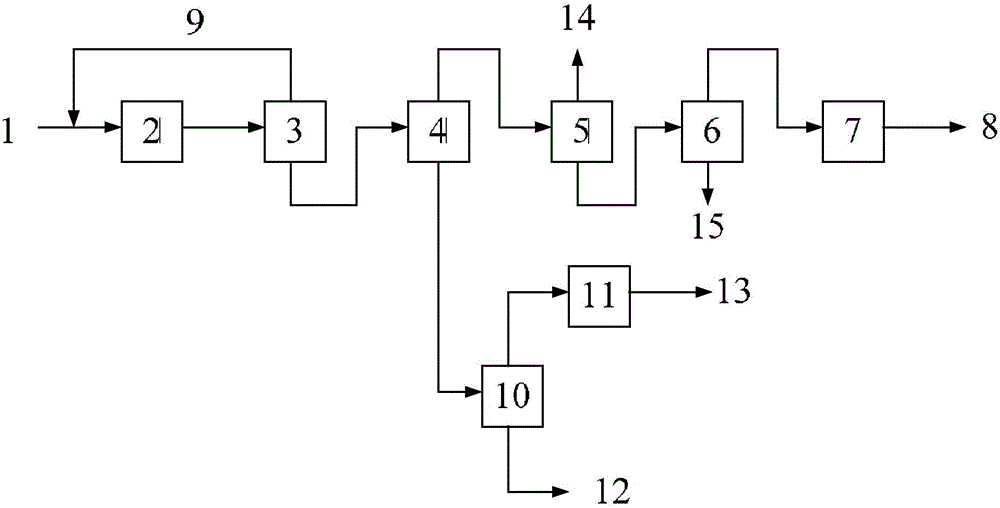

Method used

Image

Examples

Embodiment 1

[0021] The production scale of 5-ethylidene-2-norbornene ENB is 1000t / a.

[0022] The reaction raw materials cyclopentadiene 91.6kg / h and 1,3-butadiene 96.9kg / h and the solvent toluene 1.22kg / h, DEHA 0.15kg / h are sent to the first reactor through the static mixer, and the reaction pressure 3.5MPaA, reaction temperature 140°C.

[0023] The reaction product of the first reactor enters the light removal tower, and the light components and other components are separated by a rectification tower. The pressure at the top of the tower is 0.030MPaA. 1.0. The light component obtained from the top of the light removal tower is sent back to the first reactor together with the raw materials, and the product in the bottom of the tower is separated by a weight removal tower. , the mixture is obtained at the top of the tower; the distillate of the tower still is further separated by a rectification tower, the pressure at the top of the tower is 0.018MPaA, the temperature of the tower still...

Embodiment 2

[0028] According to the conditions and steps described in Example 1, the ENB production scale is 2000 t / a, cyclopentadiene 200kg / h and 1,3-butadiene 190kg / h and solvent toluene 2.50kg / h, OTMPO0.75kg / h h, through the static mixer, and then sent to the first reactor, the reaction pressure is 3.0MPaA, and the reaction temperature is 130°C.

[0029] The reaction product of the first reactor enters the light removal tower, and the light components and other components are separated by a rectification tower. The pressure at the top of the tower is 0.030MPaA. 1.0. The light component obtained from the top of the light removal tower is sent back to the first reactor together with the raw materials, and the product in the bottom of the tower is separated by a weight removal tower. The mixture is obtained at the top of the tower; the distillate of the tower bottom is further separated by a rectification tower. The top distillate can be purified to obtain the pure product dicyclopentad...

Embodiment 3

[0034] According to the conditions and steps described in Example 1, the ENB production scale is 2000t / a, cyclopentadiene 200kg / h and 1,3-butadiene 190kg / h and solvent toluene 2.50kg / h, OTMPO0.75kg / h , passed through a static mixer, and then sent to the first reactor with a reaction pressure of 3.0MPaA and a reaction temperature of 130°C.

[0035] The reaction product of the first reactor enters the light removal tower, and the light components and other components are separated by a rectification tower. The pressure at the top of the tower is 0.094MPaA. 1.8. The light component obtained from the top of the light removal tower is sent back to the first reactor together with the raw materials, and the product in the tower bottom is separated by a heavy weight removal tower. The mixture is obtained at the top of the tower; the distillate of the tower still is further separated by a rectifying tower, the pressure at the top of the tower is 0.032MPaA, the temperature of the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com