A new technique for dismantling coupling keys with liquid nitrogen

A technology of coupling and new technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult disassembly of keys and keyways, scratches on the inner wall of keyways, etc. The effect of the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] [1] Separate the small shaft of the gearbox from the coupling, and leave the key in the keyway on the side of the coupling;

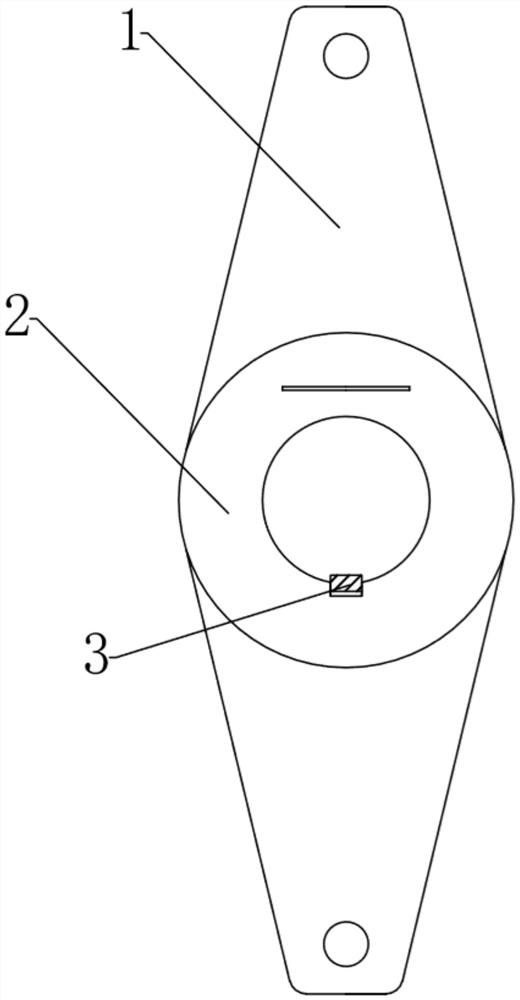

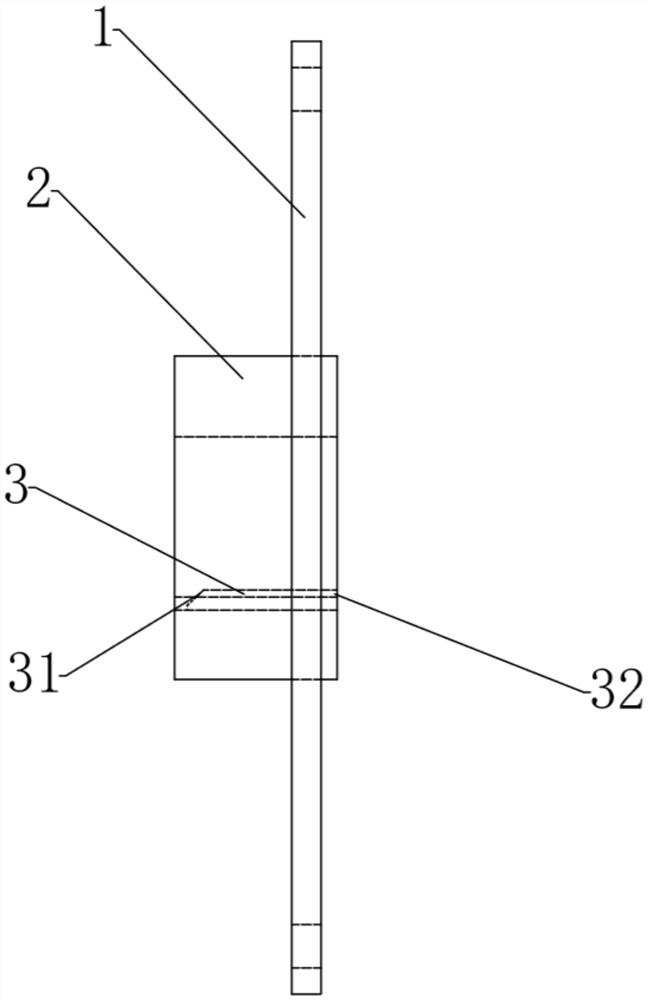

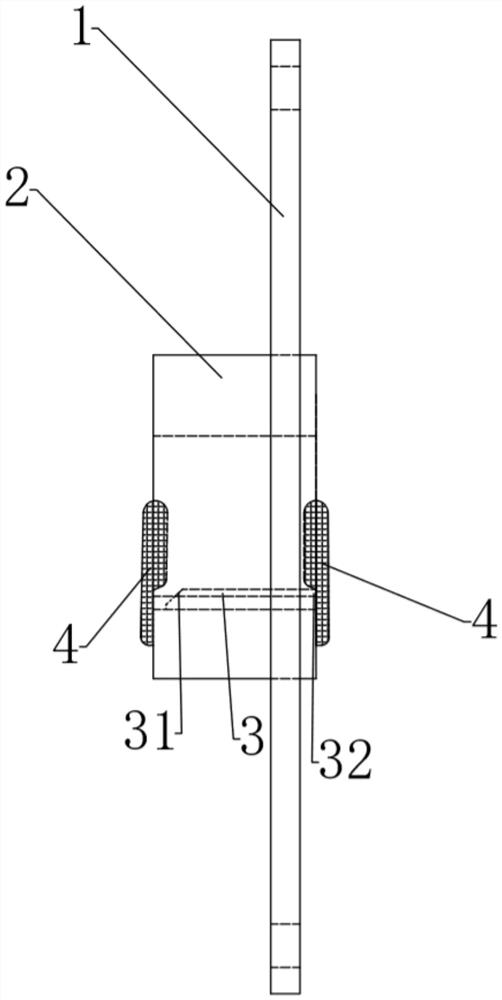

[0030] [2] The fence made of non-drying putty is used to seal the two ends of the coupling, and the fence is as follows image 3 As shown, they are respectively located at both ends of the through hole of the main body of the coupling, and the enclosure part blocks the through hole, so that the inner wall of the through hole and the enclosure form a frame-shaped space together; on the circumference of the edge of the through hole, the key and keyway It should be located within the range blocked by the enclosure so that the key and keyway are located in the box-shaped space;

[0031] [3] Pour liquid nitrogen into the frame-shaped space through the unblocked part of the through hole to soak the key and keyway. The preferred time for soaking the key and keyway in liquid nitrogen is 20-40S. If ...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] [1] Separate the small shaft of the gearbox from the coupling, and leave the key in the keyway on the side of the small shaft of the gearbox;

[0035] [2] Use non-drying putty to make a fence on the shaft extension end of the small shaft of the gearbox, so that the non-drying putty and the gearbox together form a frame-shaped space with an opening upward, so that the key and keyway are located in the frame-shaped space , for example, the frame-shaped space can be made into shapes such as strips, ellipses, or cuboids;

[0036] [3] Pour liquid nitrogen into the frame-shaped space through the upper opening of the frame-shaped space to soak the key and keyway. The preferred time for soaking the key and keyway in liquid nitrogen is 20-40S. If the liquid nitrogen evaporates or leaks within this time If it is reduced, liquid nitrogen should be replenished in time to keep the key and keyway in liquid nitrogen; after soakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com