Environment-friendly dustbin

A dustbin, environmental protection technology, applied in the direction of garbage cans, garbage collection, household utensils, etc., can solve the problems of polluting the environment, single collection of garbage, affecting the capacity of dustbins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

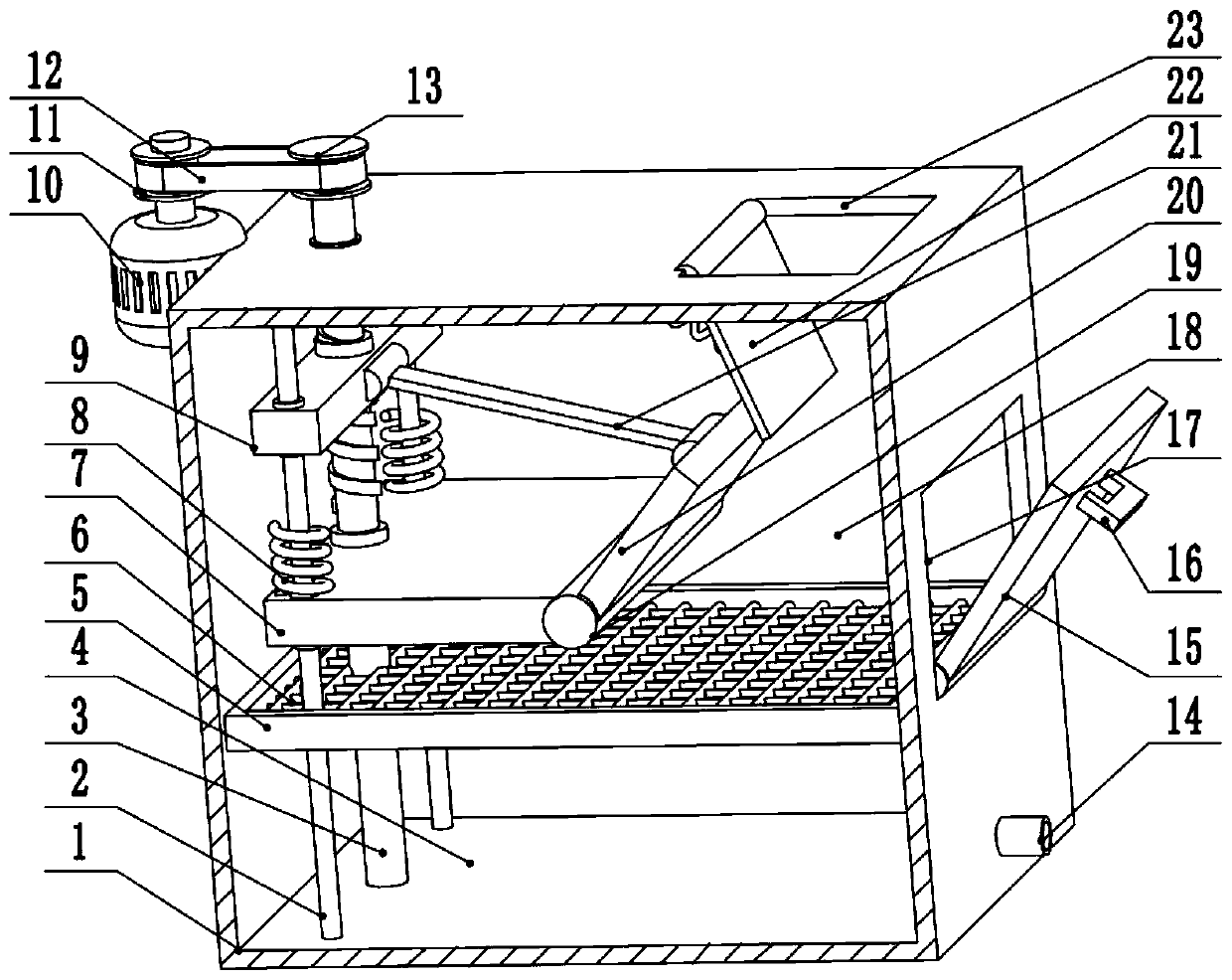

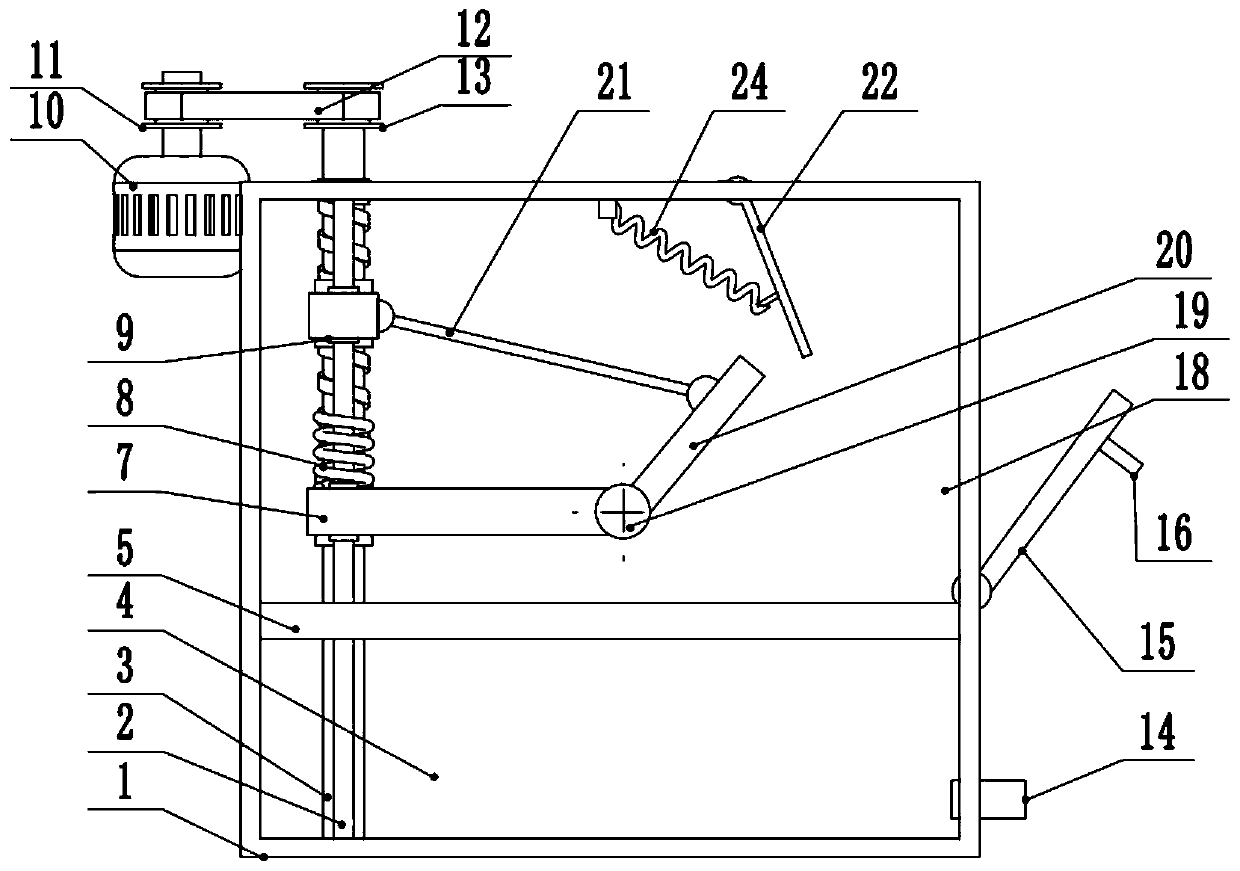

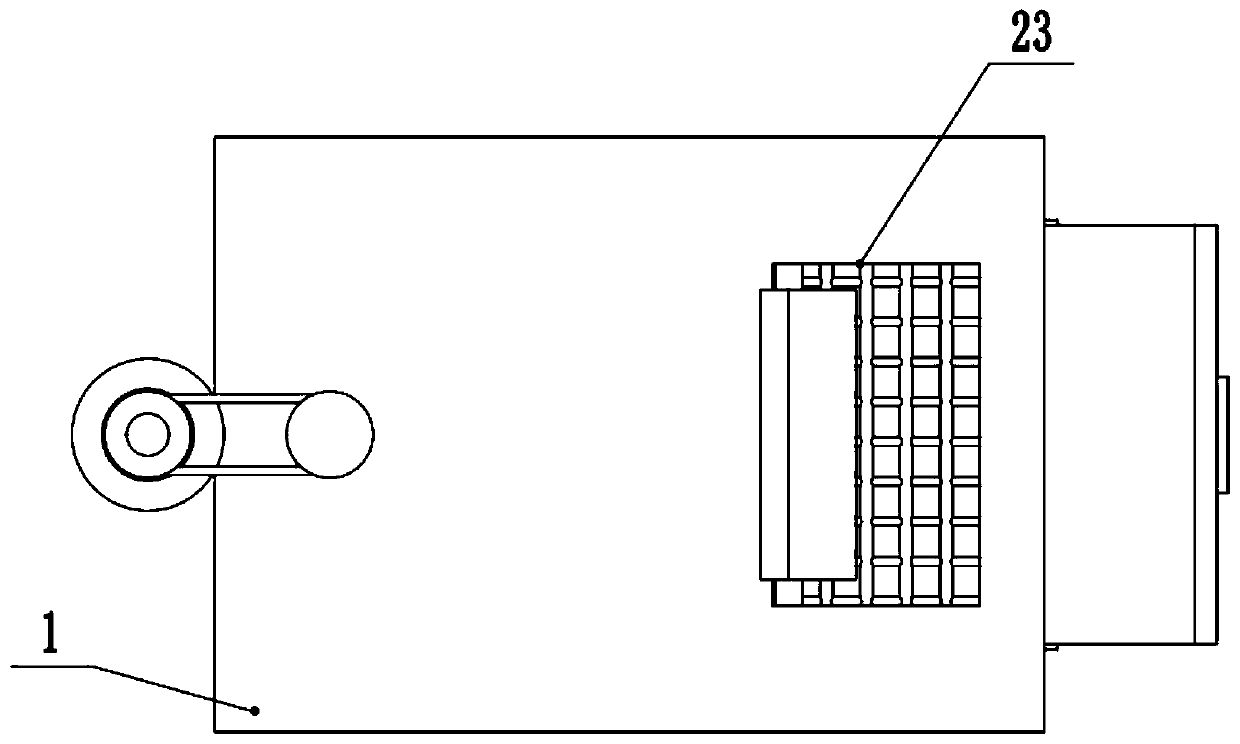

[0024] see Figure 1-3 , a kind of environmental protection dustbin, comprises dustbin 1, and the upper surface right side of dustbin 1 is provided with feed inlet 23, and feed inlet 23 is connected with the first baffle plate 22 in rotation, and the right side wall of dustbin 1 is provided with discharge Port 17, the discharge port 17 is rotatably connected to the second baffle 15, the lower surface of the second baffle 15 is provided with a handle 16, and the whole device is in a closed state when not in use through the first baffle 22 and the second baffle 15 , to prevent the leakage of gas with peculiar smell inside the dustbin 1 and affect the surrounding environment; the bottom of the dustbin 1 is provided with a filter plate 5, the inside of the filter plate 5 is provided with a filter screen 6, and the top of the filter plate 5 is provided with a solid warehouse 18 , the bottom of the filter plate 5 is provided with a liquid chamber 4, the bottom of the liquid chamber ...

Embodiment 2

[0027] The other contents of this embodiment are the same as the first embodiment, except that the lower surface of the first baffle plate 22 is connected to the lower end of the second spring 24 , and the upper end of the second spring 24 is connected to the top of the dustbin 1 . In order to facilitate the use of the first baffle plate 22, a second spring 24 is provided at the bottom of the first baffle plate 22. When it is necessary to put garbage into the device, the hand-held garbage is placed on the top of the feed port 23, and the first baffle is passed through the garbage. When the baffle plate 22 is pressed down, the first baffle plate 22 rotates clockwise, so that the feed port 23 is opened. At this time, the garbage can be put into the solid bin 18 of the device normally. After the hand is released, the second spring 24 stretches , thereby pushing the first baffle plate 22 to rotate counterclockwise, when the first baffle plate 22 rotates to the horizontal position, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com