Material taking and conveying mechanism, lifting and conveying mechanism and multi-layer circulating intelligent conveying system

A transmission mechanism and multi-layer circulation technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems that have not been widely used in other fields, affect transportation efficiency, and damage to cargo accumulation, so as to reduce the structure of the device The effect of increasing complexity, improving operational stability, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

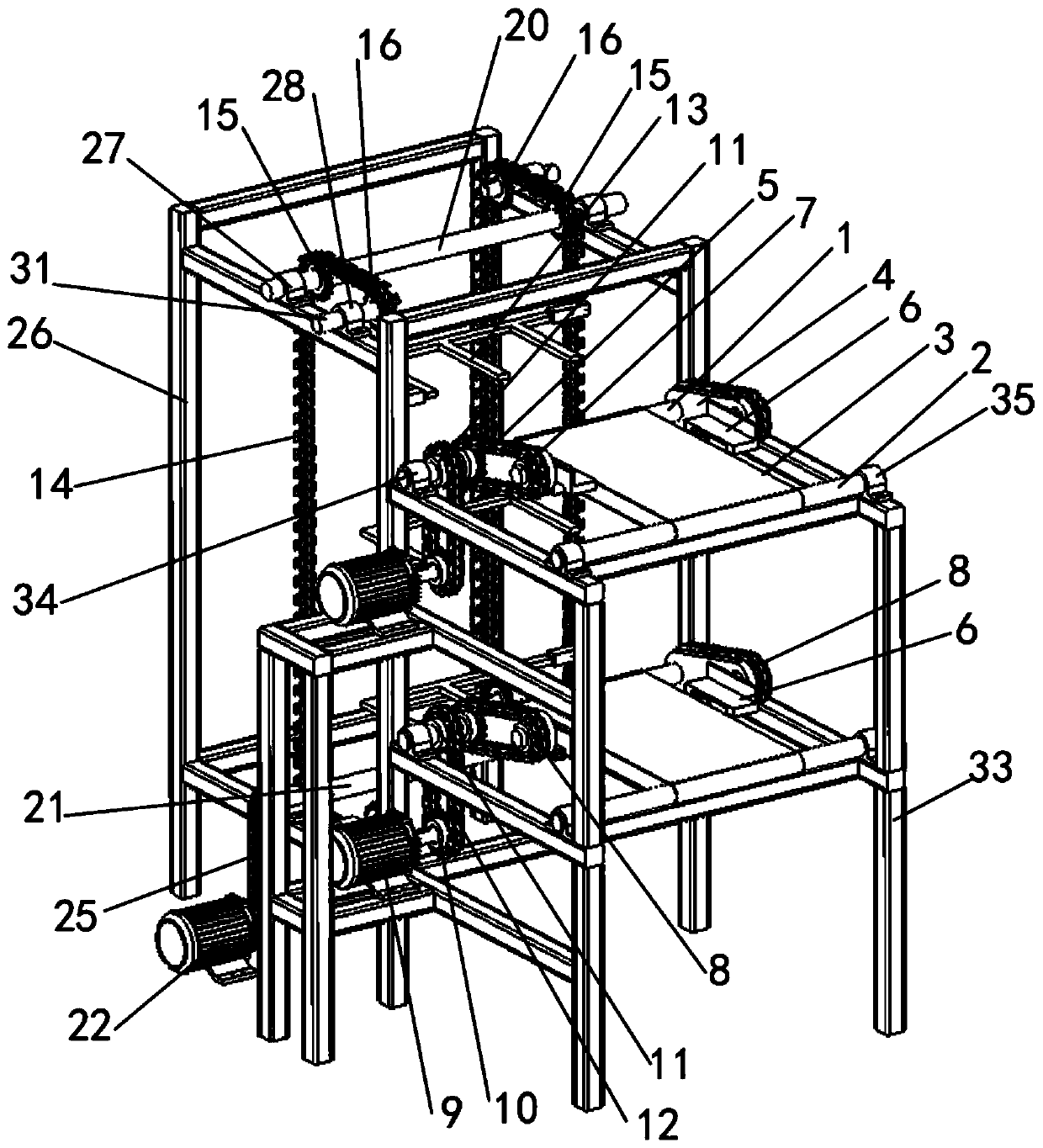

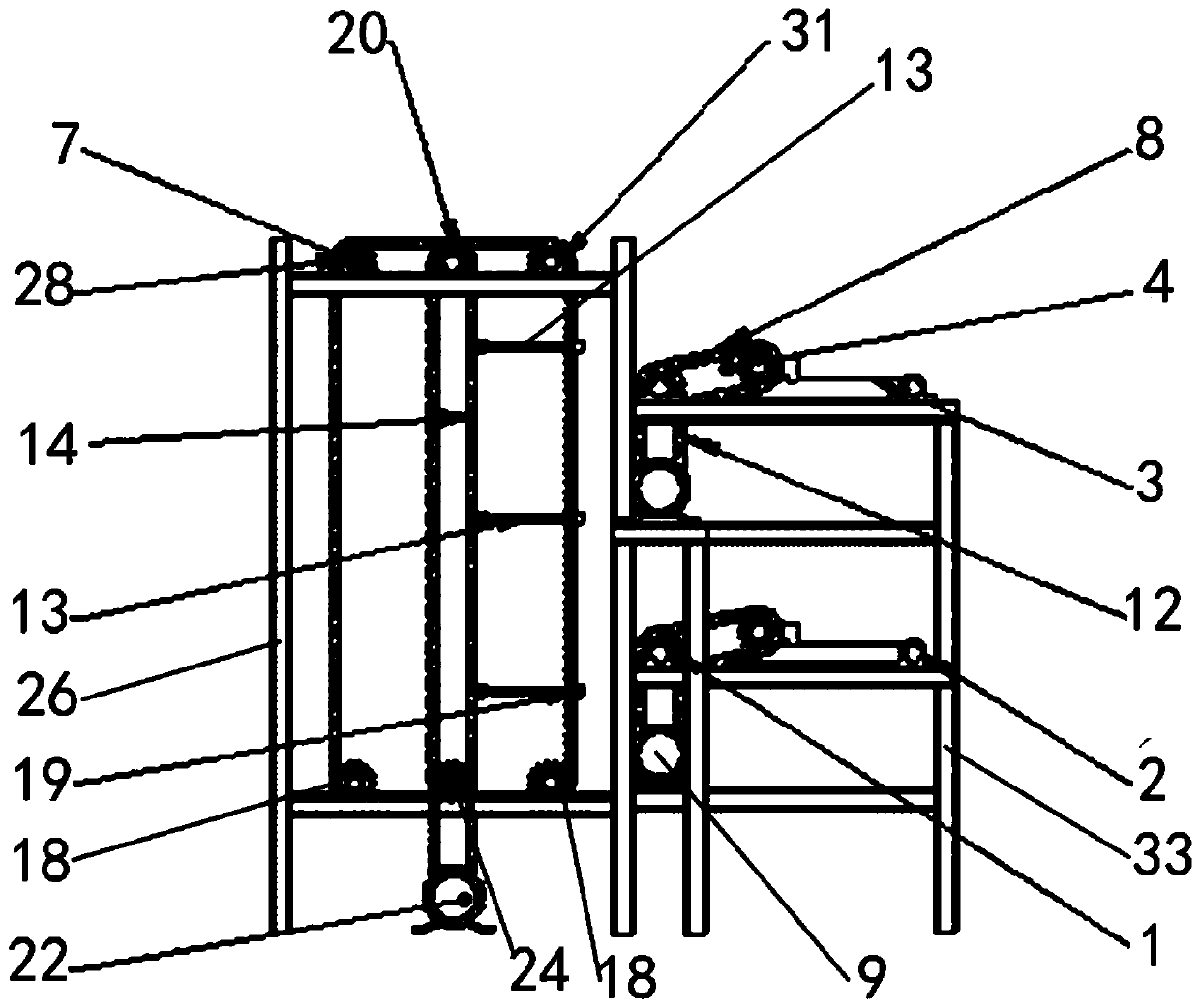

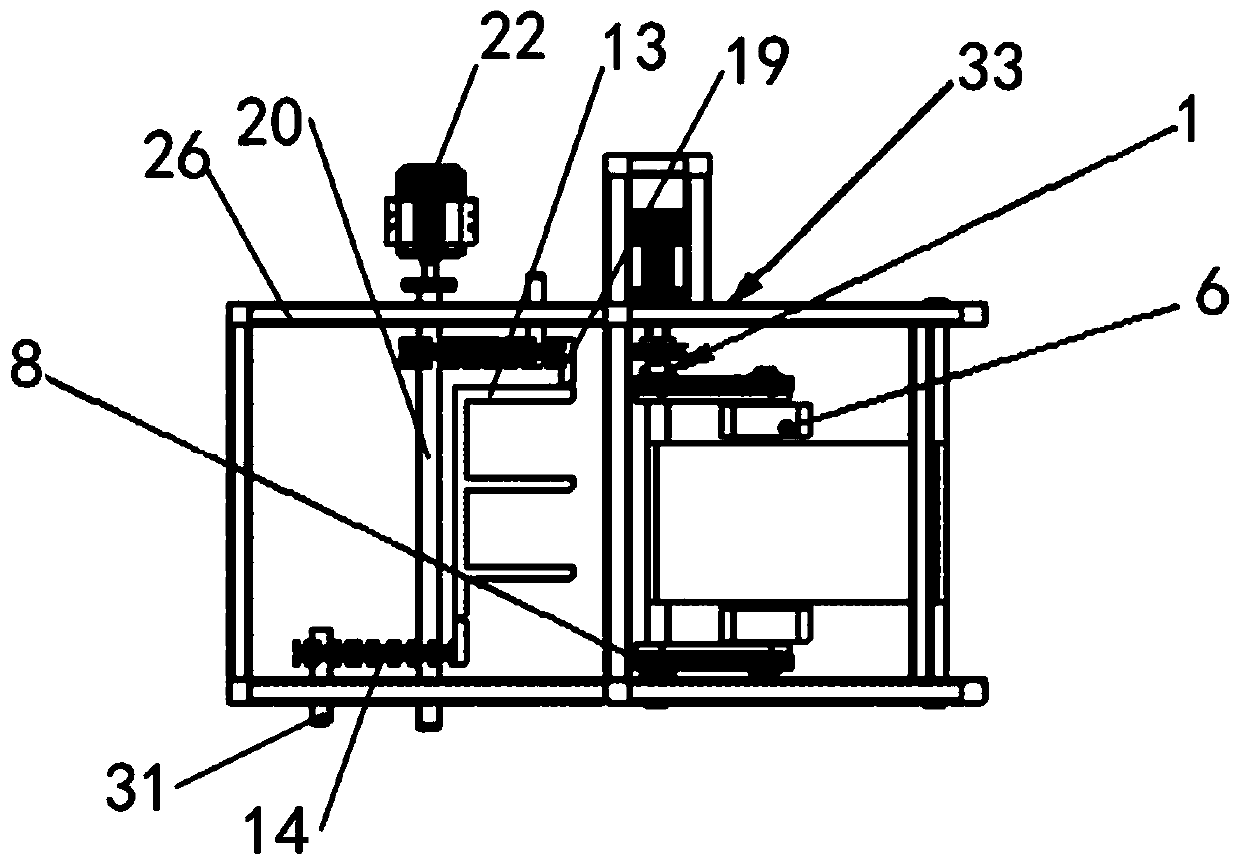

[0044] Such as Figure 1-Figure 4 As shown, the present embodiment provides a pick-up transmission mechanism, including a pick-up driving shaft 1, a pick-up driven shaft 2 and a pick-up drive mechanism connected to the pick-up drive shaft 1, a pick-up drive shaft 1 and a pick-up drive shaft. A conveyor belt 3 is arranged between the driven shafts 2; a pick-up arm 4 and a pick-up drive sprocket 5 are installed on the pick-up drive shaft 1, and a tray drive assembly is provided at the end of the pick-up arm 4; the tray drive assembly includes a tray 6 And the fetching driven sprocket 7, between the tray 6 and the fetching driven sprocket 7, a linkage shaft is arranged, the linkage shaft and the fetching arm 4 rotate and cooperate, and the fetching driving sprocket 5 and the fetching driven sprocket 7 Be provided with fetching chain 8 between.

[0045] Since there is a conveyor belt 3 between the fetching driving shaft 1 and the fetching driven shaft 2, when the fetching driving...

Embodiment 2

[0050] This embodiment is optimized and defined on the basis of the above-mentioned embodiment 1.

[0051] In order to improve the smooth effect of fetching objects, two fetching arms 4 and two fetching driving sprockets 5 are symmetrically arranged on the fetching driving shaft 1 .

[0052] Concretely, two pick-up driving sprockets 5 are positioned at the outsides of two pick-up arms 4, pick-up driven sprockets 7 and tray 6 are respectively arranged on the outside and inside of pick-up arms 4, and pick-up chains 8 are positioned at the pick-up arm 4. The outer side of the object arm 4.

Embodiment 3

[0054] A lifting transmission mechanism, comprising two oppositely arranged transmission assemblies, a plurality of racks 13 installed on the transmission assemblies and a transmission drive mechanism for driving the transmission assemblies, the transmission assembly includes a sprocket and a chain meshed with the sprocket 14. The sprocket includes an upper transmission sprocket and a lower transmission sprocket. The upper transmission sprocket includes an upper main transmission sprocket 15 and an upper slave transmission sprocket 16. The two upper slave transmission sprockets 16 are respectively arranged on two upper main transmission sprockets. On both sides of the line between the sprocket wheels 15, the lower transmission sprocket includes the following main transmission sprocket and the lower slave transmission sprocket 18, and the two lower slave transmission sprockets 18 are respectively arranged between the two lower main transmission sprockets The both sides of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com