A wear-resistant ball valve capable of high temperature and high pressure

A high-temperature and high-pressure technology, applied in the field of wear-resistant ball valves, can solve problems such as mechanical wear, poor wear resistance, and high friction of ball valve parts, and achieve the effects of improving service life, high temperature resistance, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

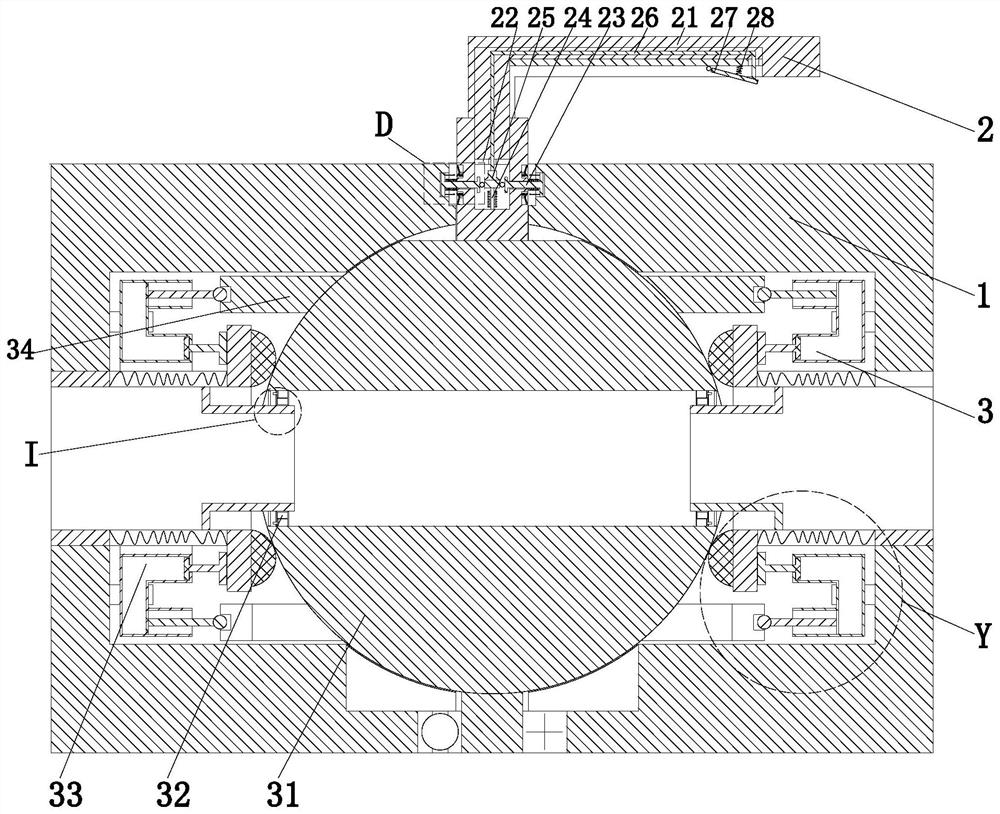

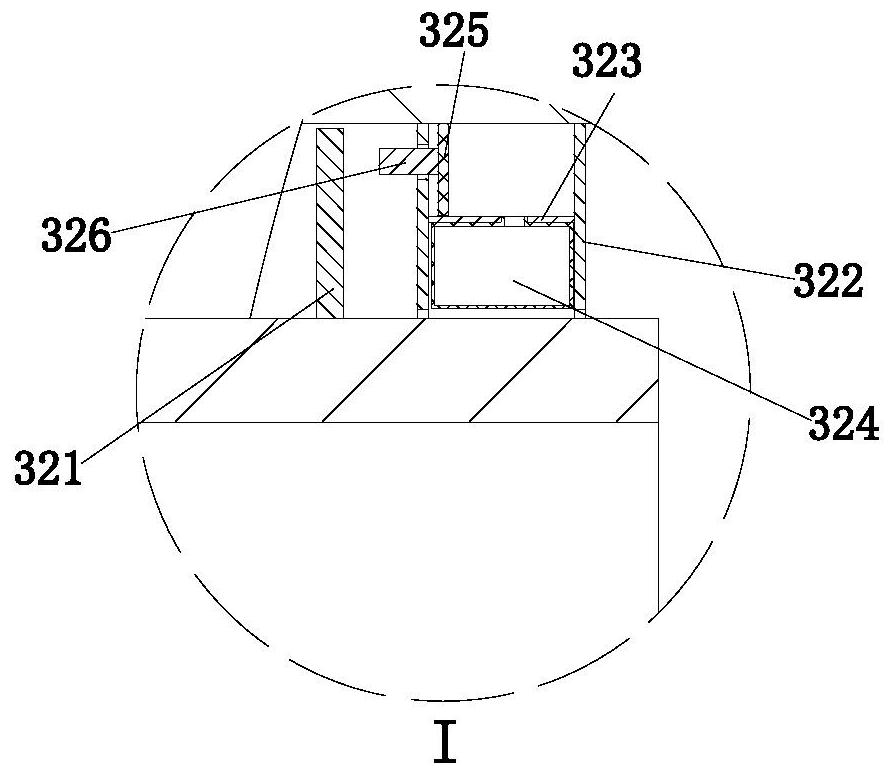

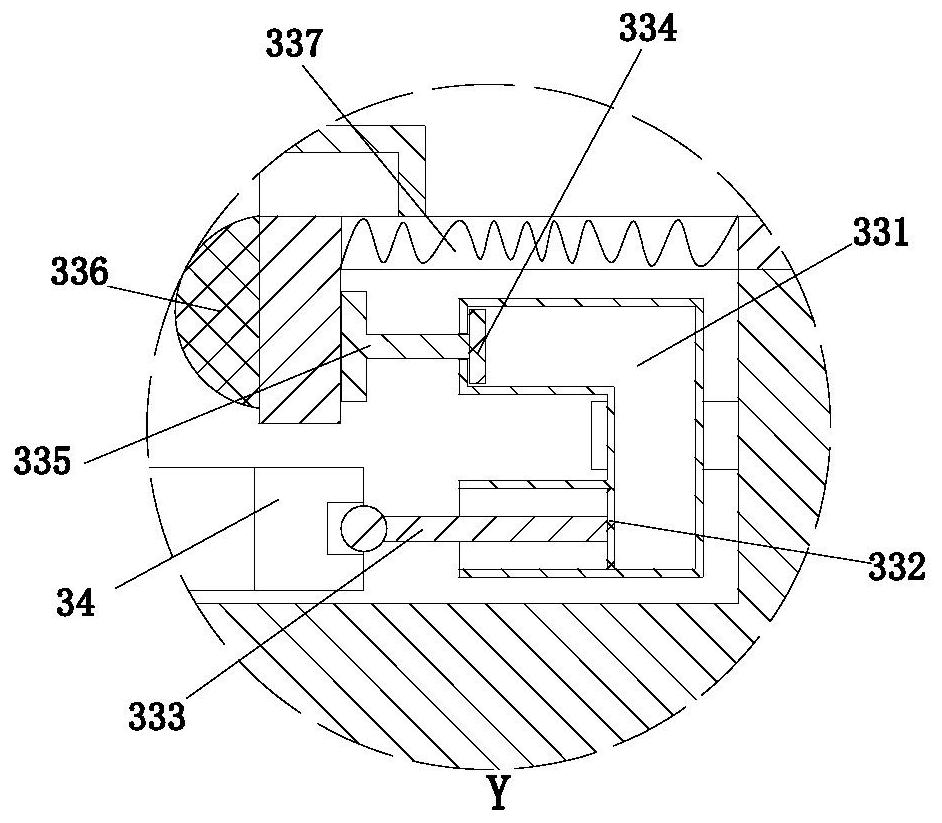

[0027] Such as Figure 1 to Figure 5 As shown, a wear-resistant ball valve that can withstand high temperature and high pressure includes a valve body 1, a control hole is opened on the upper end of the valve body 1, a control assembly 2 is arranged in the control hole, and an actuator assembly 3 is installed on the lower end of the control assembly 2. The actuator assembly 3 is arranged in the valve body 1 .

[0028] The control assembly 2 includes a control rod 21 installed on the execution ball 31, the control rod 21 is located in the control hole, the control rod 21 is provided with a threading chamber, the lower end of the control rod 21 is provided with a control chamber 22, the threading chamber and the control chamber 22 Unicom, the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com