High-density polyethylene HDPE winding structural wall Q-shaped tube

A high-density polyethylene and structural wall technology, which is applied in the field of pipelines, can solve the problems of hard foundation, reduced pipe strength, and damage to the arc-shaped corrugated structure, and achieves the effect of simple structure, increased contact surface, and improved overall structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

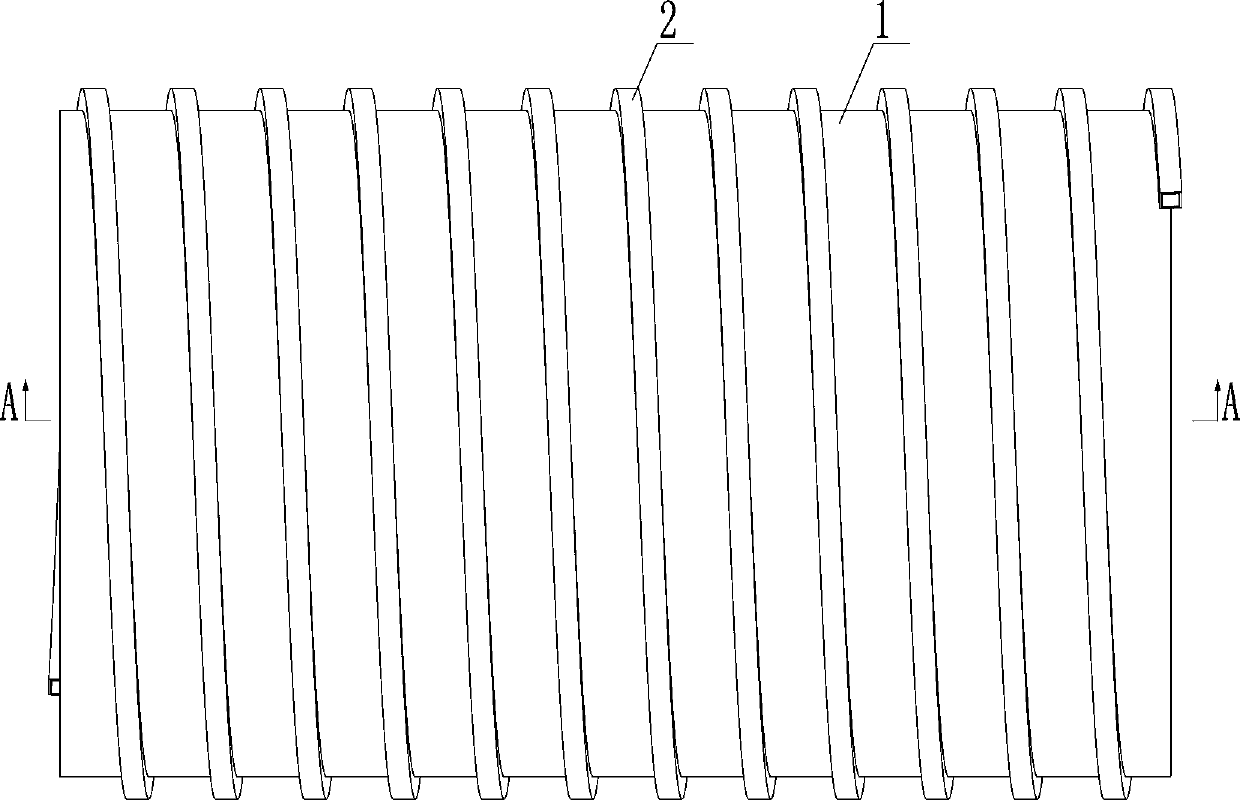

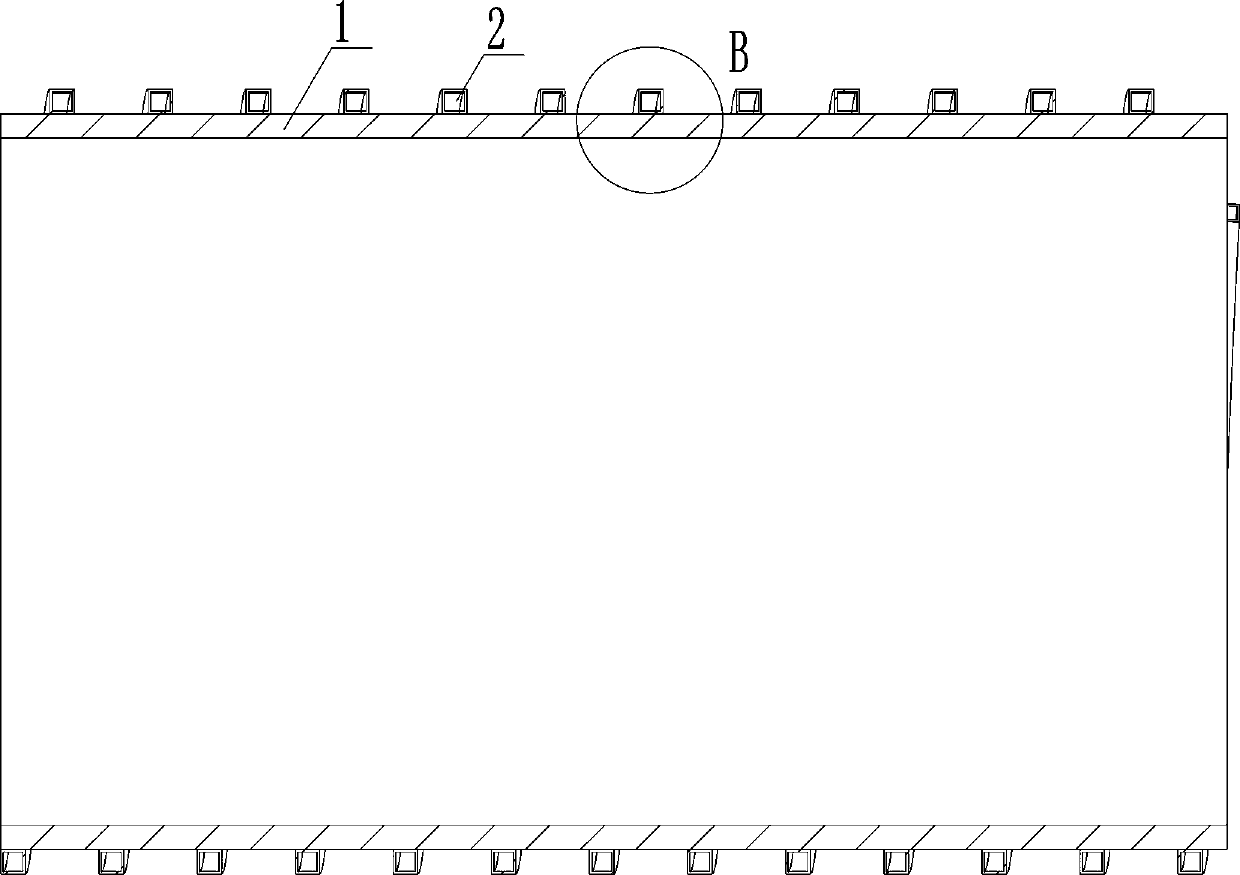

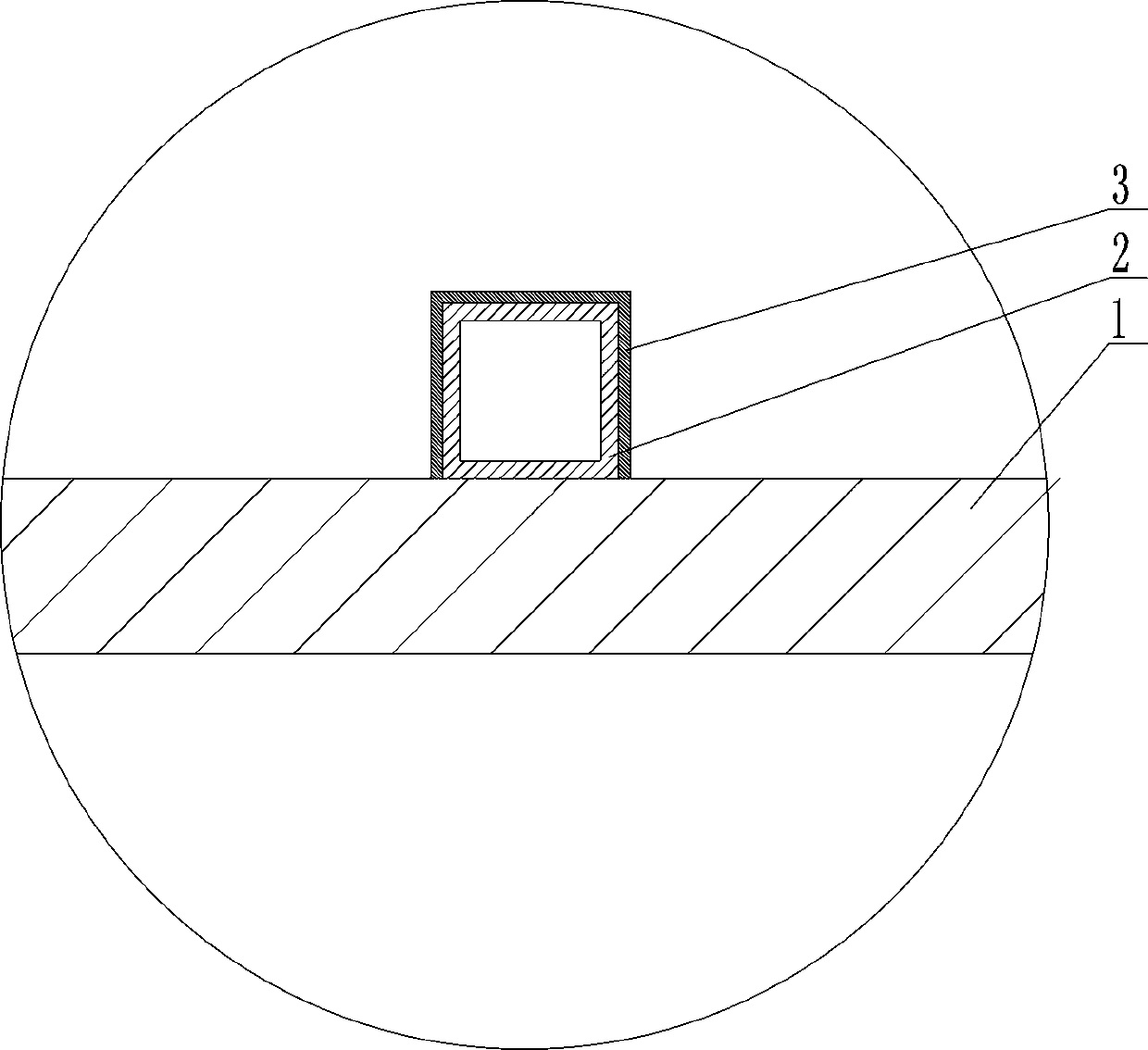

[0026] Such as Figure 1~Figure 5 Among them, a high-density polyethylene HDPE winding structure wall Q-shaped pipe, which includes a pipe body 1, a square pipe 2 and a cladding layer 3; the square pipe 2 is located on the outer wall of the pipe body 1 and contacts it, along the Extending axially, the cladding layer 3 covers the square tube 2 and the outer wall of the tube body 1; the square tube 2 protrudes from the outer wall of the tube body 1. The structure is simple. By setting the square tube 2 on the outer wall of the tube body 1, the tube body 1 and the square tube 2 are covered by the cladding layer 3, the overall structural strength is improved through the square tube 2, and the contact support is increased through the square tube 2 and the foundation. Surface, good load-bearing performance, high structural strength, not easy to break.

[0027] In a preferred solution, the square tube 2 on the outer wall of the tube body 1 is in a spiral shape. The structure is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com