Contact vibration detection device, rotating machine provided with same, and contact vibration detection method

A technology of contact vibration and detection device, which is applied in the field of rotating machinery and can solve the problems of inability to detect contact vibration and lack of vibration detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

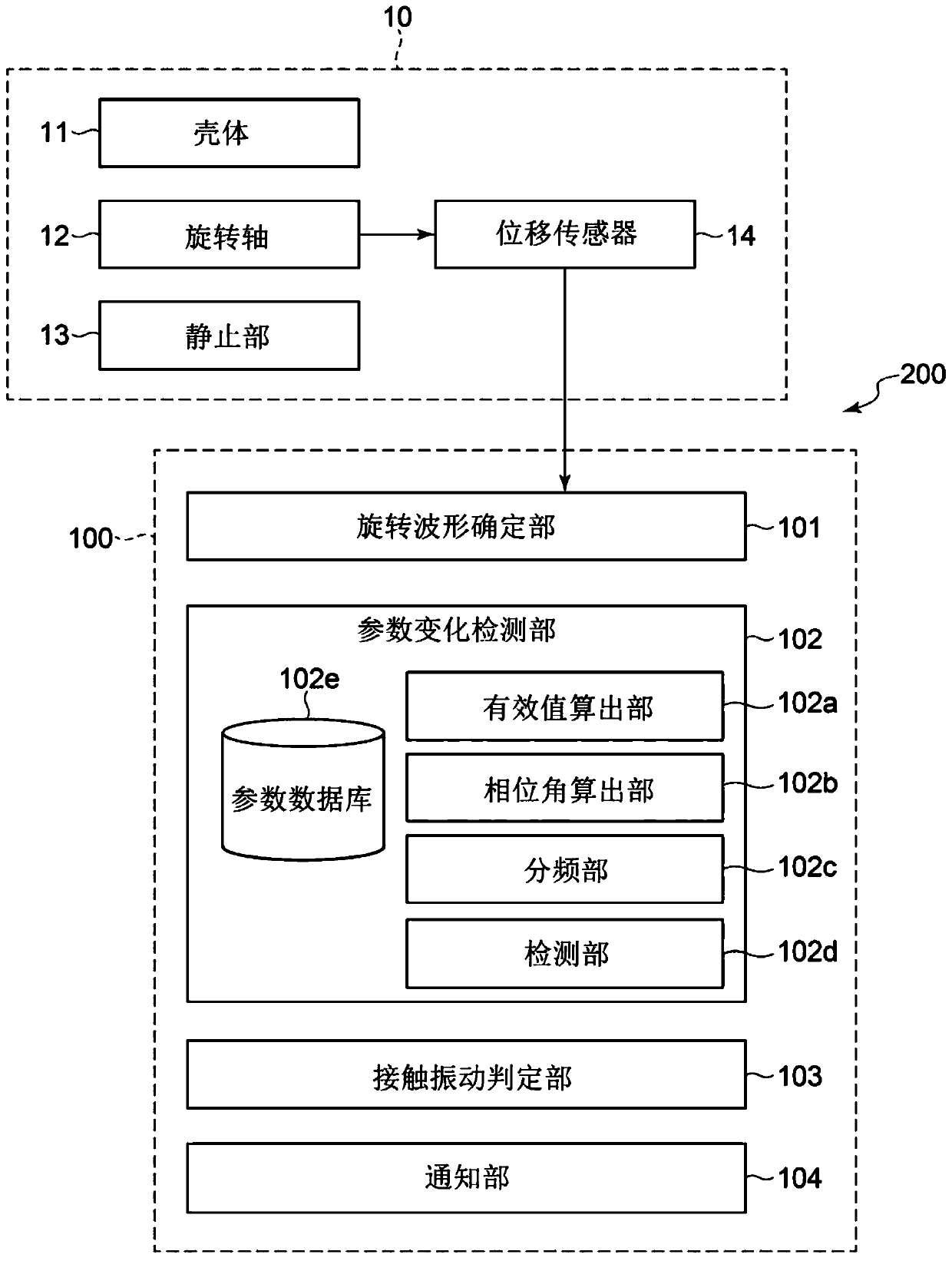

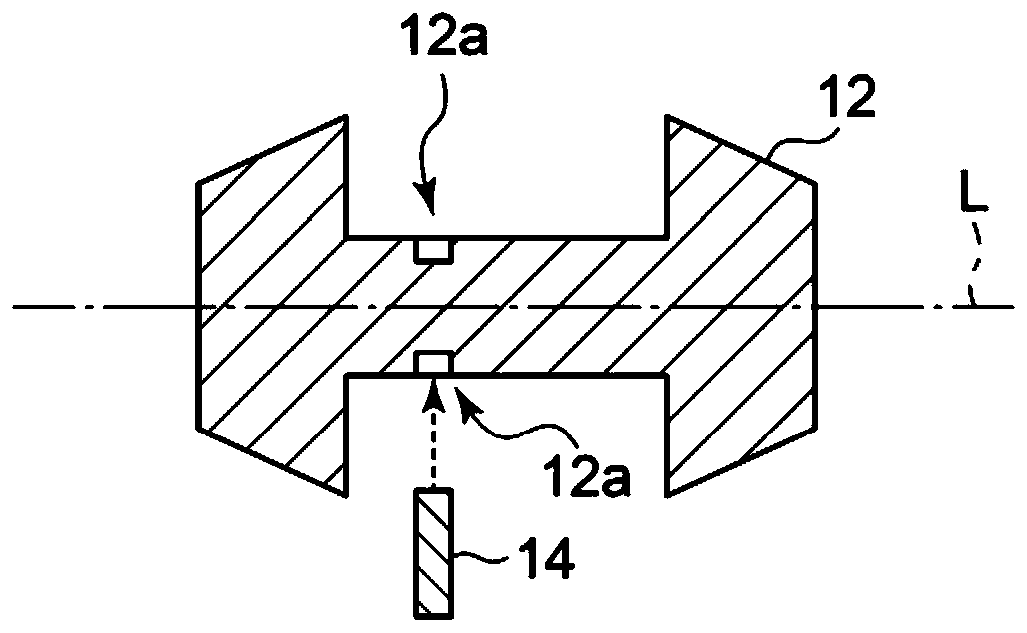

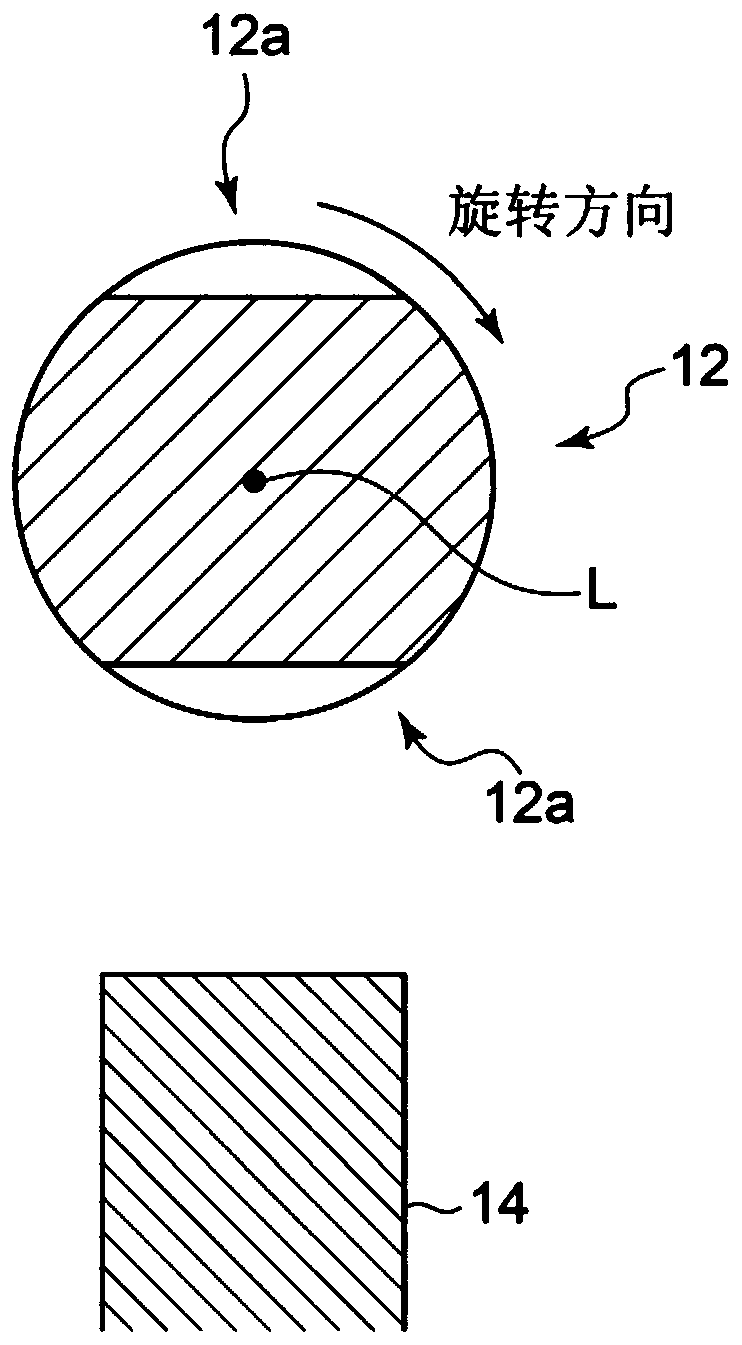

[0044] Hereinafter, several embodiments of the present invention will be described with reference to the drawings. However, the following contents described as the embodiments or the contents described in the drawings are merely examples, and can be arbitrarily changed and implemented without departing from the gist of the present invention. In addition, each embodiment can be implemented in any combination of two or more. In addition, in each embodiment, the same reference numerals are given to common components, and redundant descriptions are omitted in order to simplify the description.

[0045] In addition, the dimensions, materials, shapes, and relative arrangements of the components described in the embodiments or shown in the drawings are not intended to limit the scope of the present invention to these, and are merely illustrative examples.

[0046] For example, expressions such as "in a certain direction", "along a certain direction", "parallel", "orthogonal", "center", "...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com