Apparatus for manufacturing parts and related methods

A technology for parts and prefabricated parts, used in the manufacture of tools, forging/pressing/hammer devices, forging/pressing/hammering machines, etc., which can solve the problems of time-consuming, expensive, and undesired, avoid storage costs, and simplify maintenance. cost, effect of avoiding the need for refurbishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

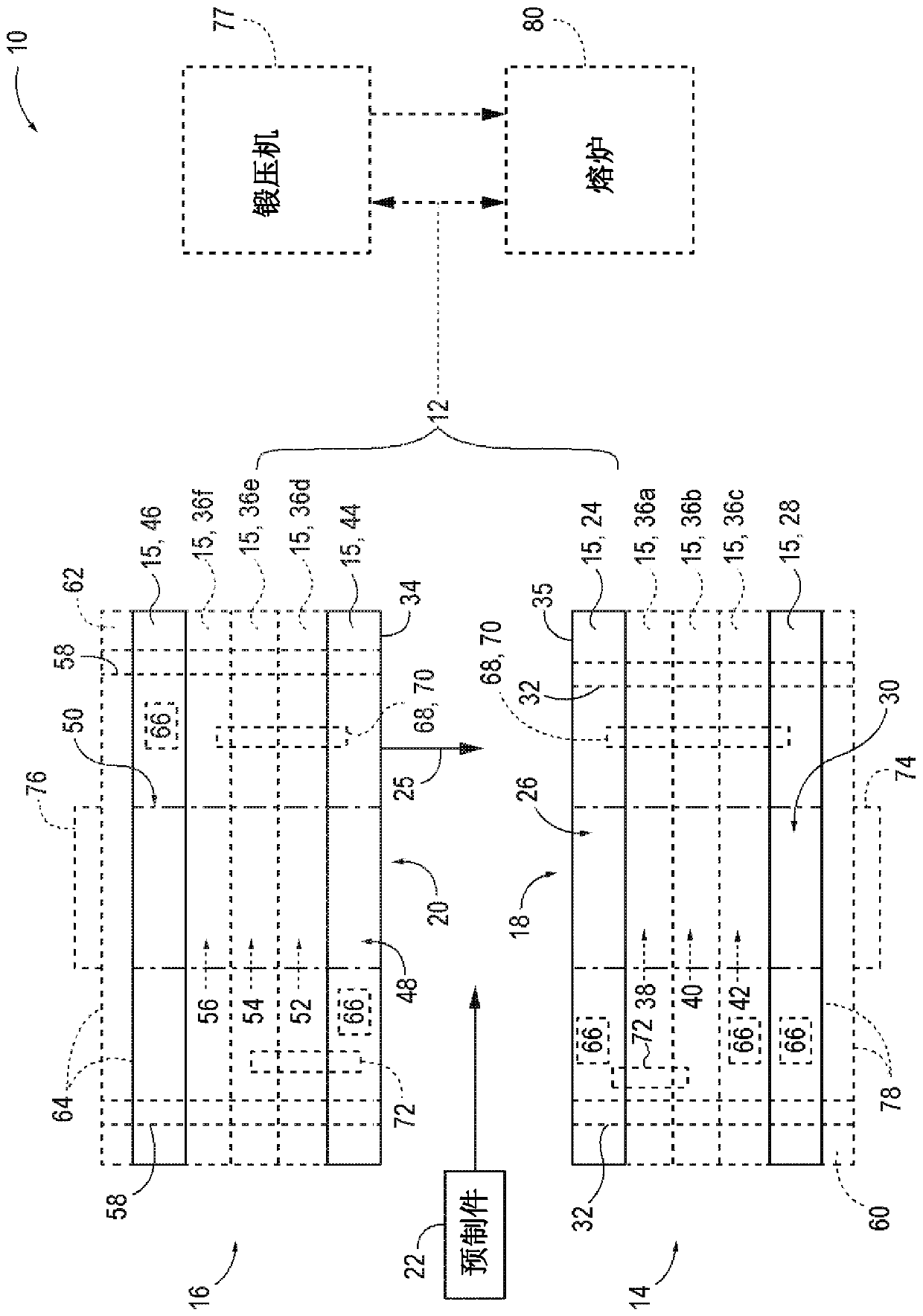

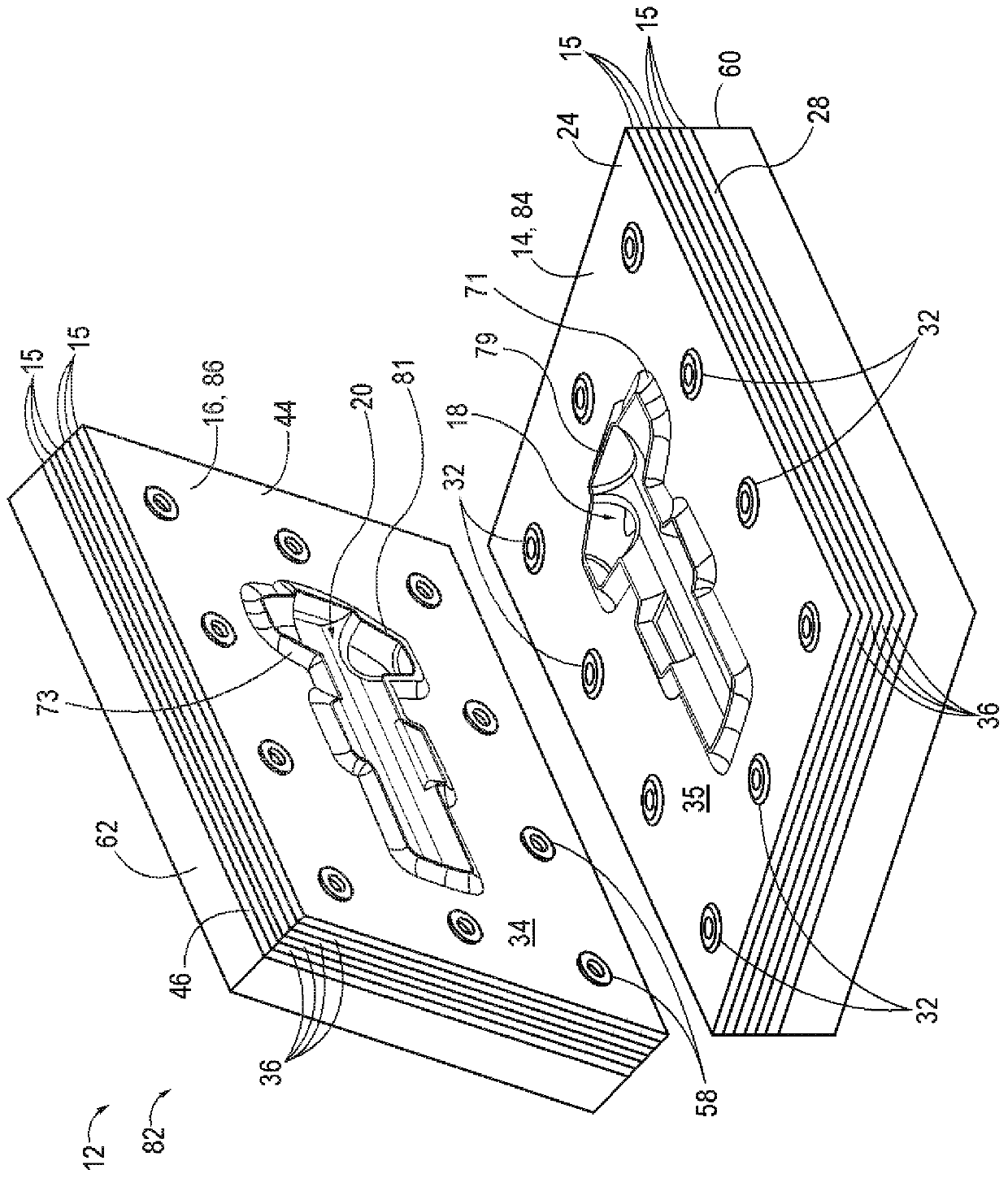

[0020] Unlike traditional forging dies, which are ground from solid blocks of material, the presently disclosed forging dies can be assembled from individual layers of material, which saves time and cost compared to traditional forging dies, Details are as follows. figure 1 An example of a system 10 is shown schematically and generally includes a forging die 12 formed from a first die half 14 and a second die half 16 . First mold half 14 and / or second mold half 16 may include mold cavities (e.g., first mold cavity 18 formed in first mold half 14 and / or second mold cavity formed in second mold half 16 20 ), the mold cavity configured to receive at least a portion of the preform 22 . When so configured, first mold half 14 and second mold half 16 may be press forged together, forcing preform 22 to form the desired part during the forging process. Generally, in the figures, elements that may be included in a given example are shown in solid lines, while elements that are optiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com